irondad01

150+ Posts

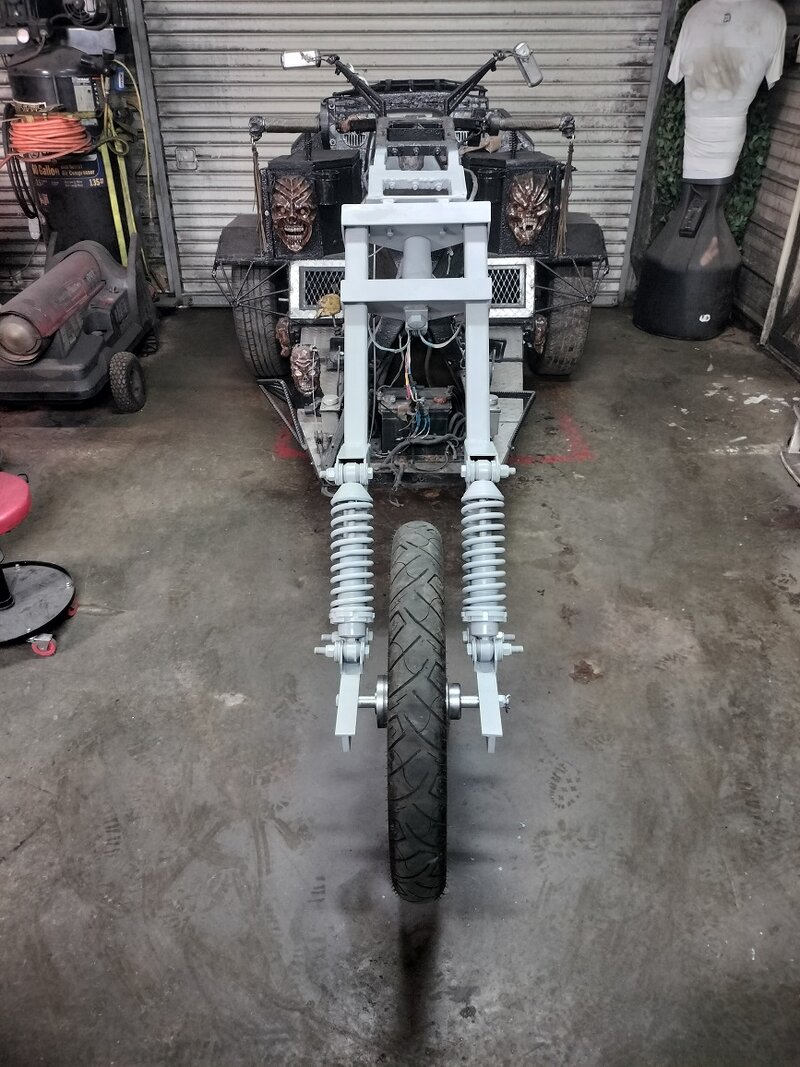

Will cutting 1/8" off help or hurt setting the preload on your neck bearings?

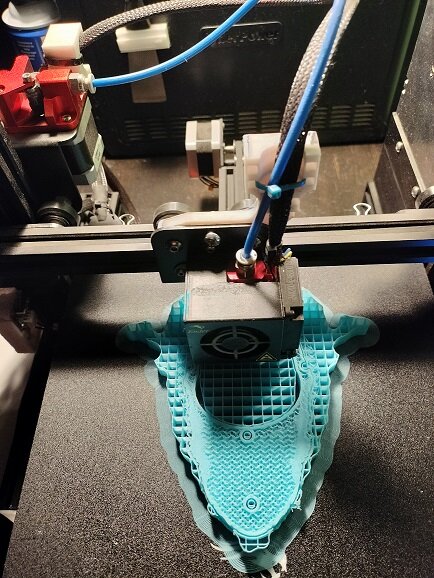

On the wheel bearings, do you have a local store that sells bearings and seals? I have one near me and it's nice to be able to look at them before you buy. They carry name brand stuff ( Timken, etc. ) that's not too expensive. They can measure your old ones and match them.

On the wheel bearings, do you have a local store that sells bearings and seals? I have one near me and it's nice to be able to look at them before you buy. They carry name brand stuff ( Timken, etc. ) that's not too expensive. They can measure your old ones and match them.