Fowler

◇BUILD IT BOB◇

- Thread starter

- #31

It can and will.I can't contribute anything mathwise, but could trail changes be made by changing rocker length?

Unless I figured something wrong my rockers will have to be long.

Remember I cant change the neck angle. I could change the angle at the trees but don't want to do that

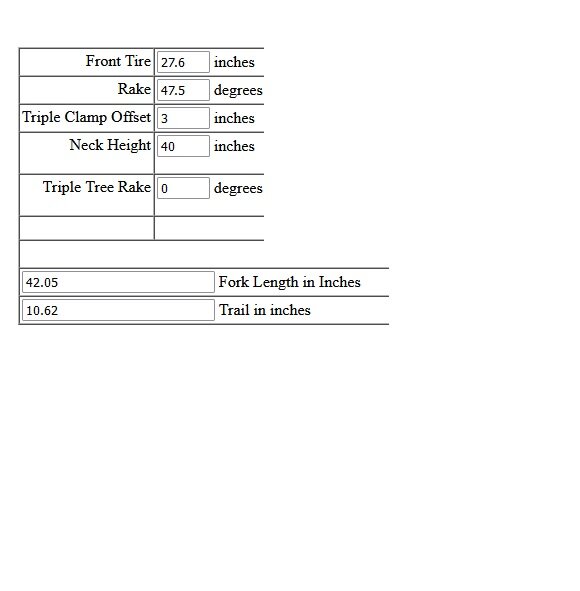

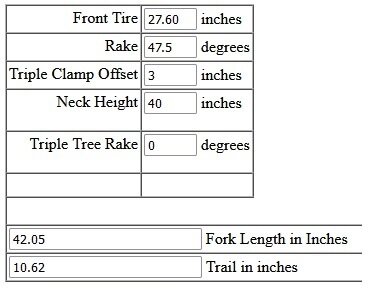

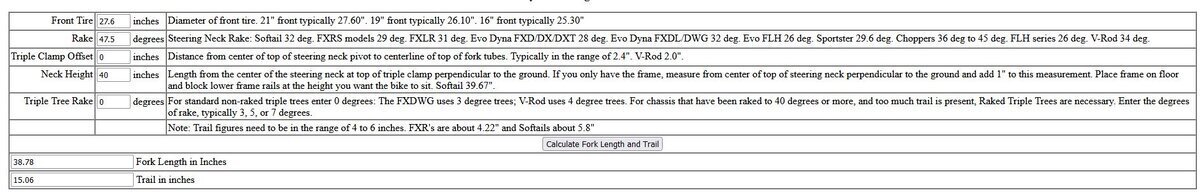

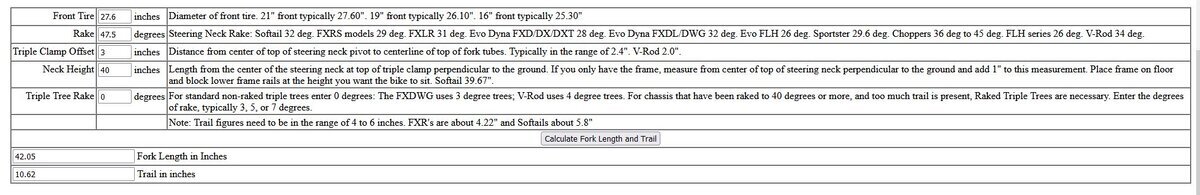

RB Racing Fork Length and Trail Calculator

With a 3" offset I get 10.62 trail. If I have 6" rockers that will take it down to a 5.62 trail (if I am correct). Not going to be able to make the 2" trail I wanted

Since I cant change the neck angle I am limited as to what I can do.

I hope I am figuring this correctly