Fowler

◇BUILD IT BOB◇

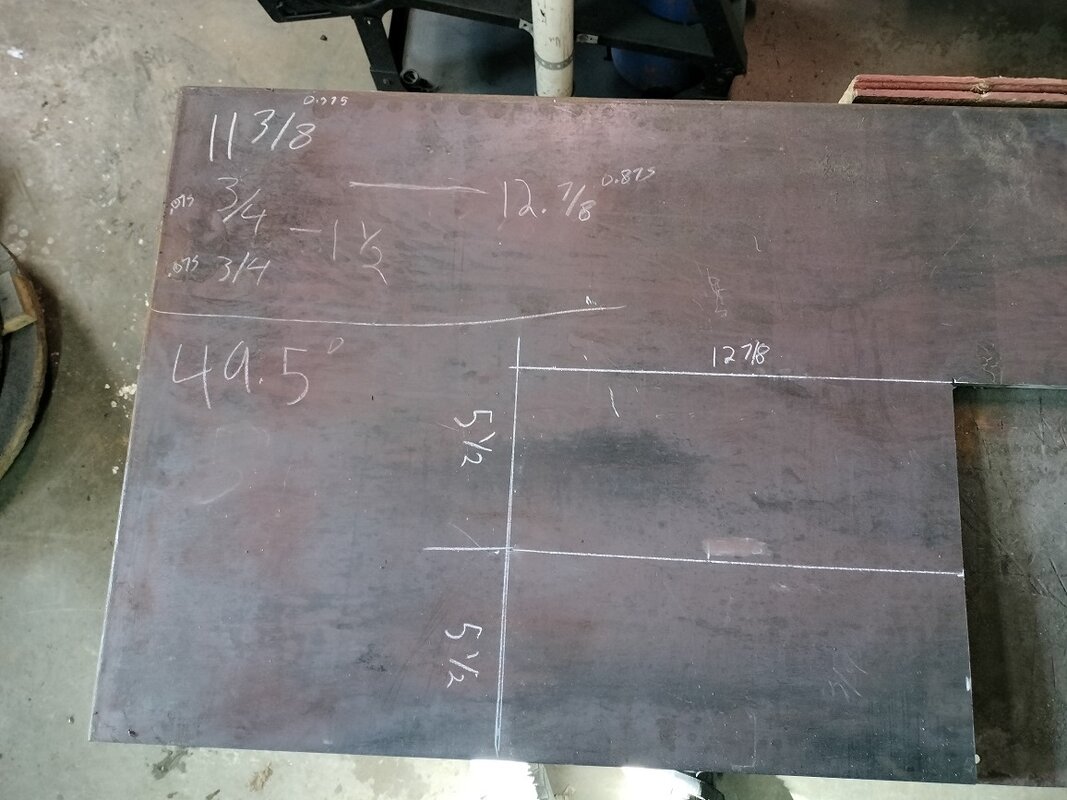

I have not posted on this side for a long time Im usually on the Non-VW side now. But im working on my VW Trike now. So here I am

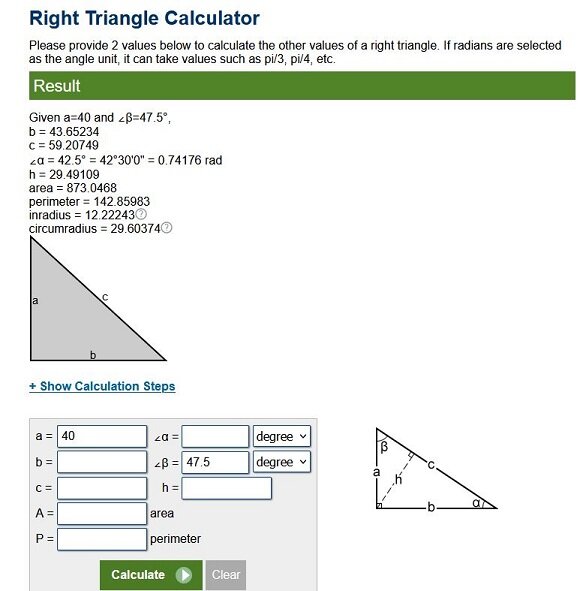

Anyway... I want to build new front forks for my VW trike. I want to build a leading link setup and was thinking of using VW coilover

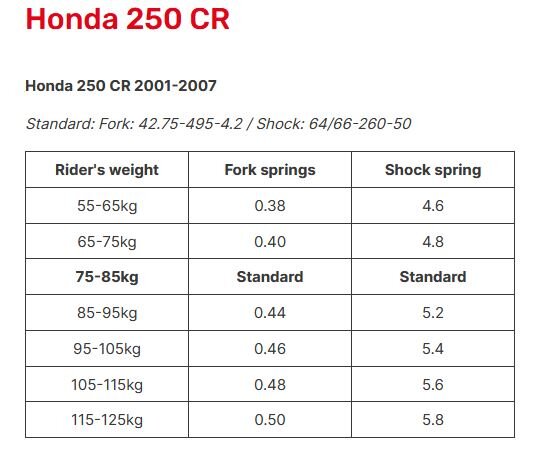

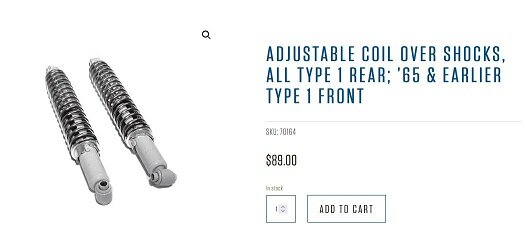

Does anyone know the average spring weight of something like these?

Anyone ever try this with these

Anyway... I want to build new front forks for my VW trike. I want to build a leading link setup and was thinking of using VW coilover

Does anyone know the average spring weight of something like these?

Anyone ever try this with these