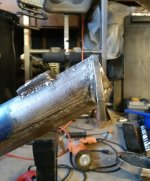

That 3/4 stem is a bit odd.

Most stuff is built with the harley parts which are 1 inch and readily available in many configurations.

Back yard builds are usually whatever 2 wheeler that could be found laying around.

I would not be scared to cut the neck off it and weld in a harley style and use a harley style front end.

But then I do forget that everyone is not like me.

What resources do you have?

Most stuff is built with the harley parts which are 1 inch and readily available in many configurations.

Back yard builds are usually whatever 2 wheeler that could be found laying around.

I would not be scared to cut the neck off it and weld in a harley style and use a harley style front end.

But then I do forget that everyone is not like me.

What resources do you have?