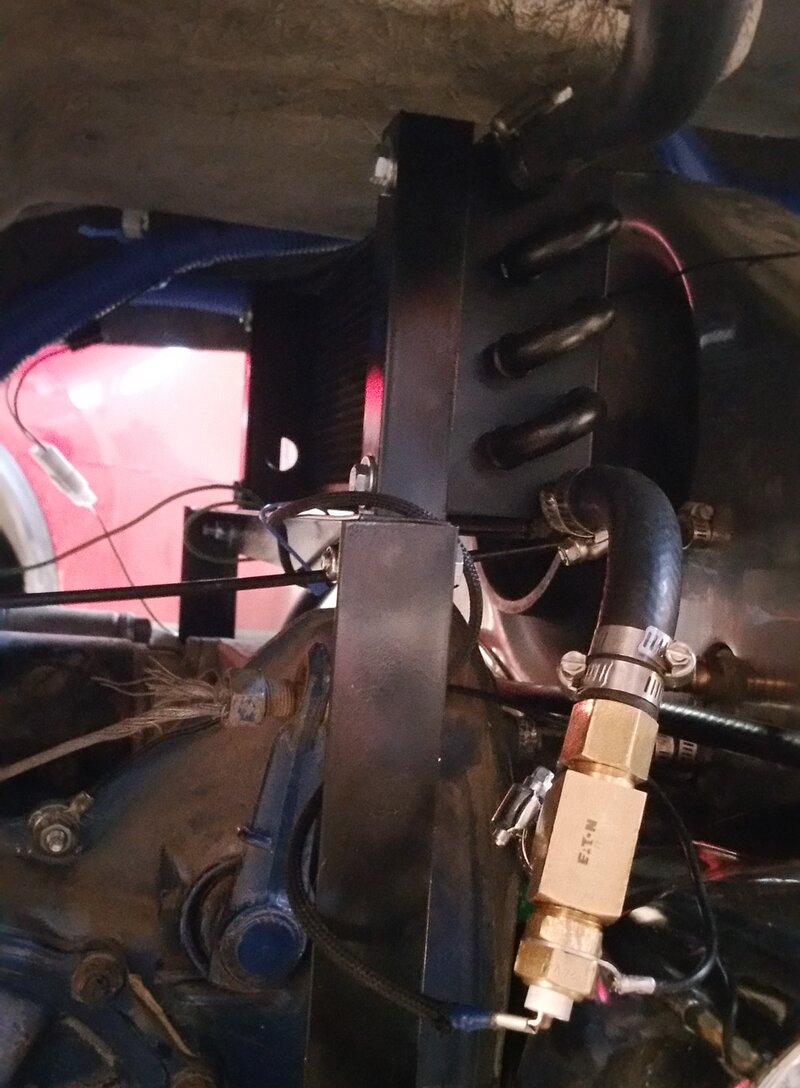

Mounting a cooler over the fan intake might not be ideal.....but with an open engine and light load you should be fine.

I would be more worried about have the correct springs on the oil control than I would be be worried about the cooler over intake.

Pull the fan housing off and clean out the mouse nest, dirt dobbers, wasp nest.

Change the oil.

Adjust the valves.

Put a simple cooler on it.

Clean out the carbs.

Clean the points.

Change the condenser.

Change the spark plugs.

Crank it up.

Monitor the oil pressure.

If it has decent pressure then don't worry about what pump is in it.

Drive it.

Drive it some more.

Check compression psi to see if it has evened out.

If then you have oil pressure and the compression is not crazy uneven and the head temp and oil temp stay reasonable. Run the fool out of it.

You have a modified engine you should be happy with the power. One day when it starts getting weak...low psi on 3....low oil pressure...ect.

Then start playing with the insides and put a better fan housing and oil cooler set up on it.

I would be more worried about have the correct springs on the oil control than I would be be worried about the cooler over intake.

Pull the fan housing off and clean out the mouse nest, dirt dobbers, wasp nest.

Change the oil.

Adjust the valves.

Put a simple cooler on it.

Clean out the carbs.

Clean the points.

Change the condenser.

Change the spark plugs.

Crank it up.

Monitor the oil pressure.

If it has decent pressure then don't worry about what pump is in it.

Drive it.

Drive it some more.

Check compression psi to see if it has evened out.

If then you have oil pressure and the compression is not crazy uneven and the head temp and oil temp stay reasonable. Run the fool out of it.

You have a modified engine you should be happy with the power. One day when it starts getting weak...low psi on 3....low oil pressure...ect.

Then start playing with the insides and put a better fan housing and oil cooler set up on it.