- Thread starter

- #241

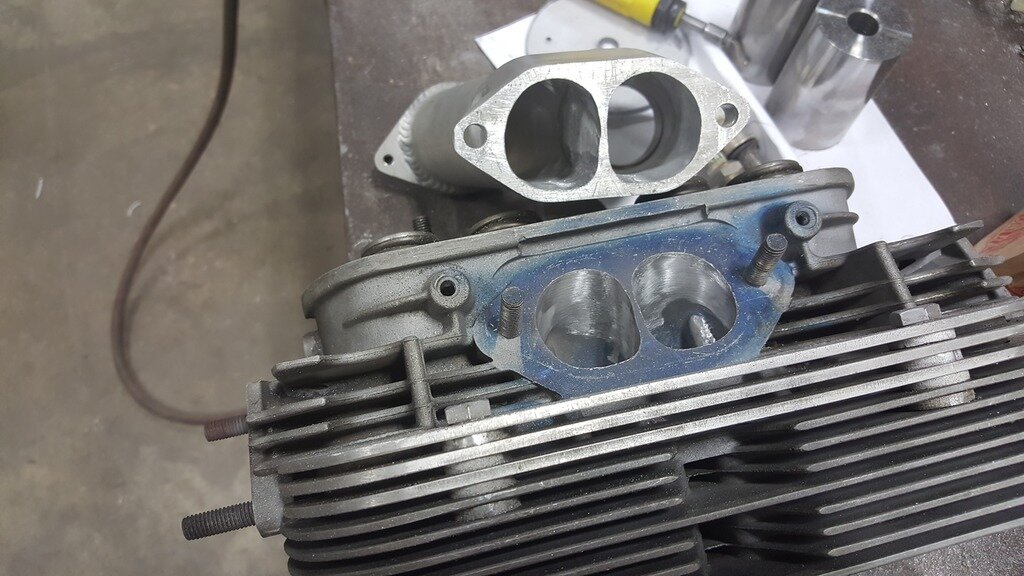

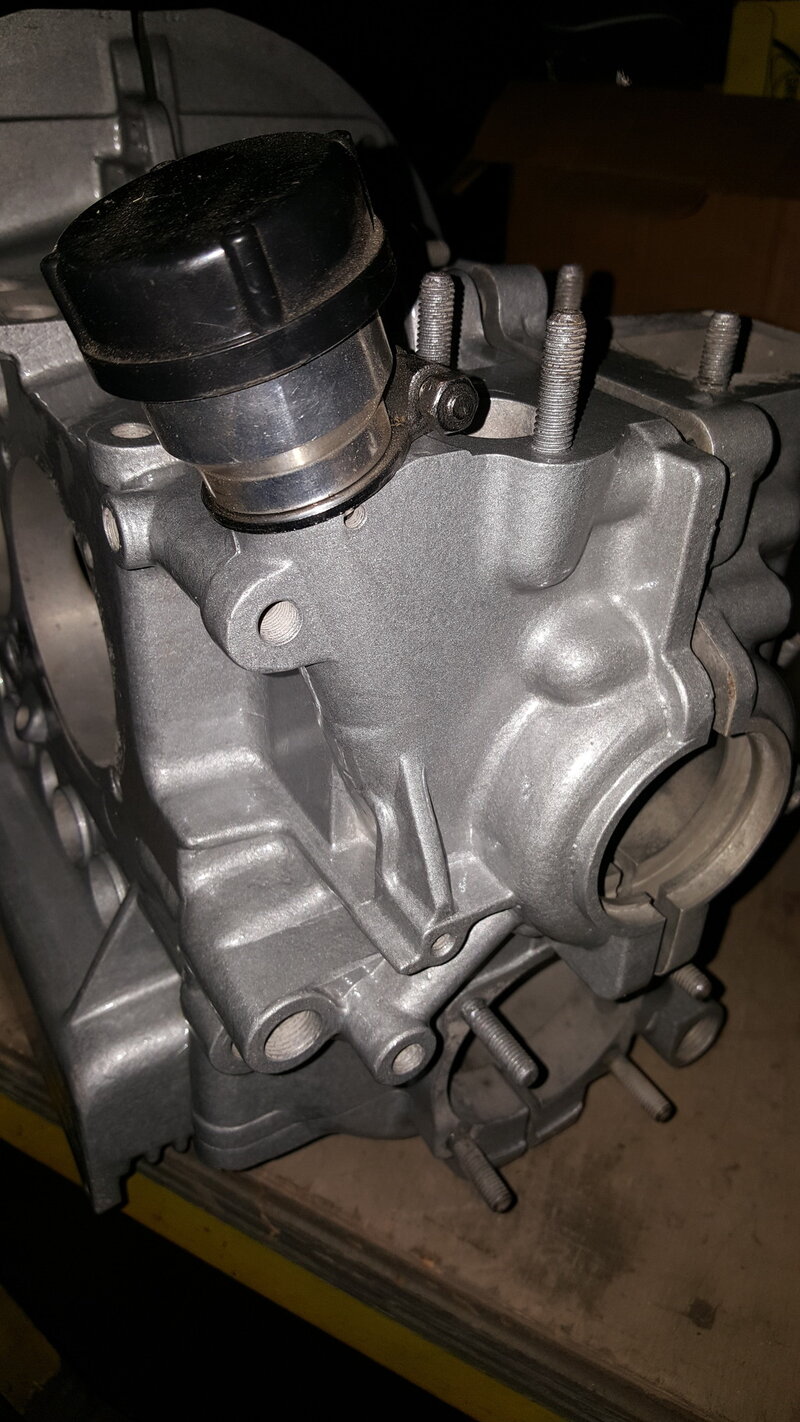

Remember the pump cover from a few pages back?

Trying to finish it up. Completing the machining of the smaller details.

Drill and tap to size.

For the oil thermo switch on the fan.

So it is nearly finished.

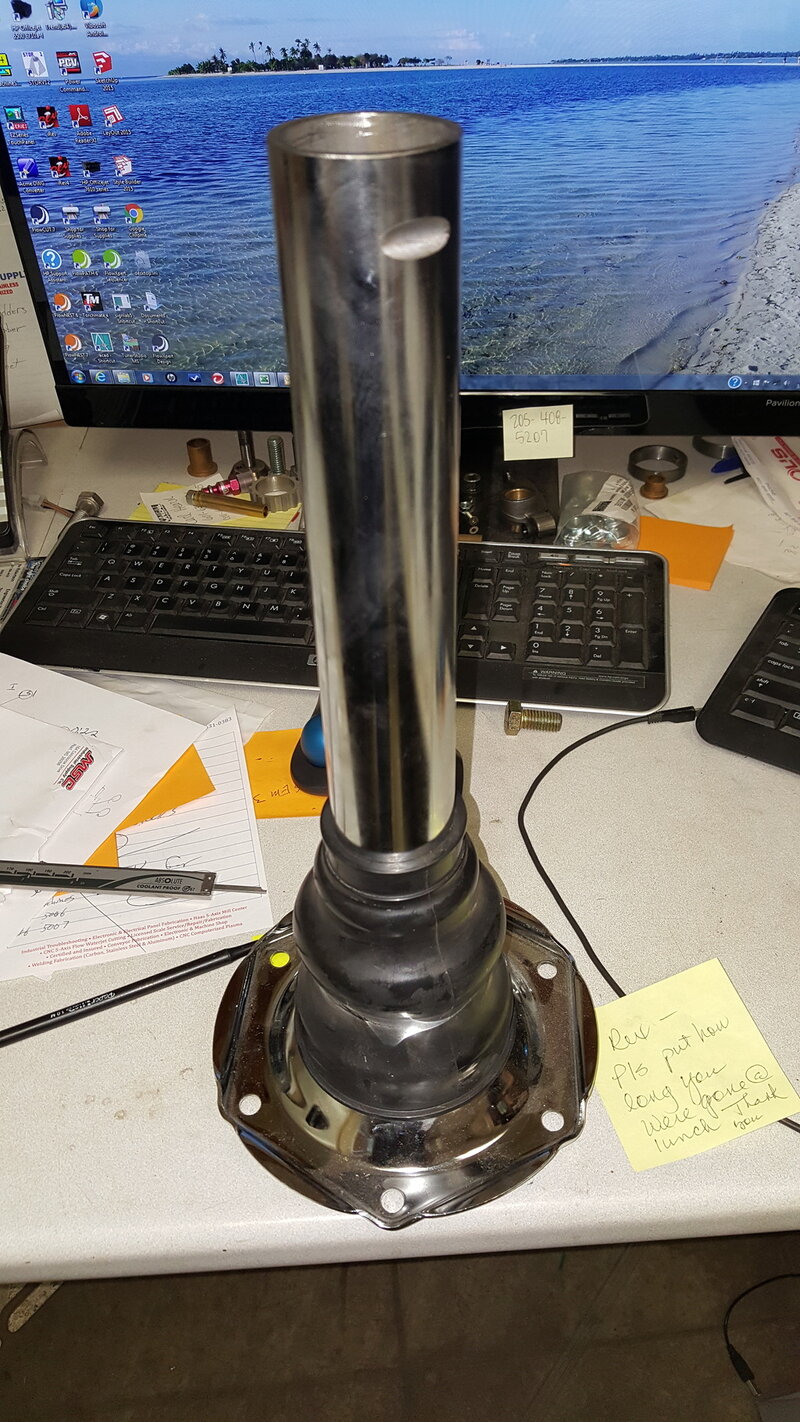

Finished the oil port through the bolt center.

Now to seal the bolt head to hole.

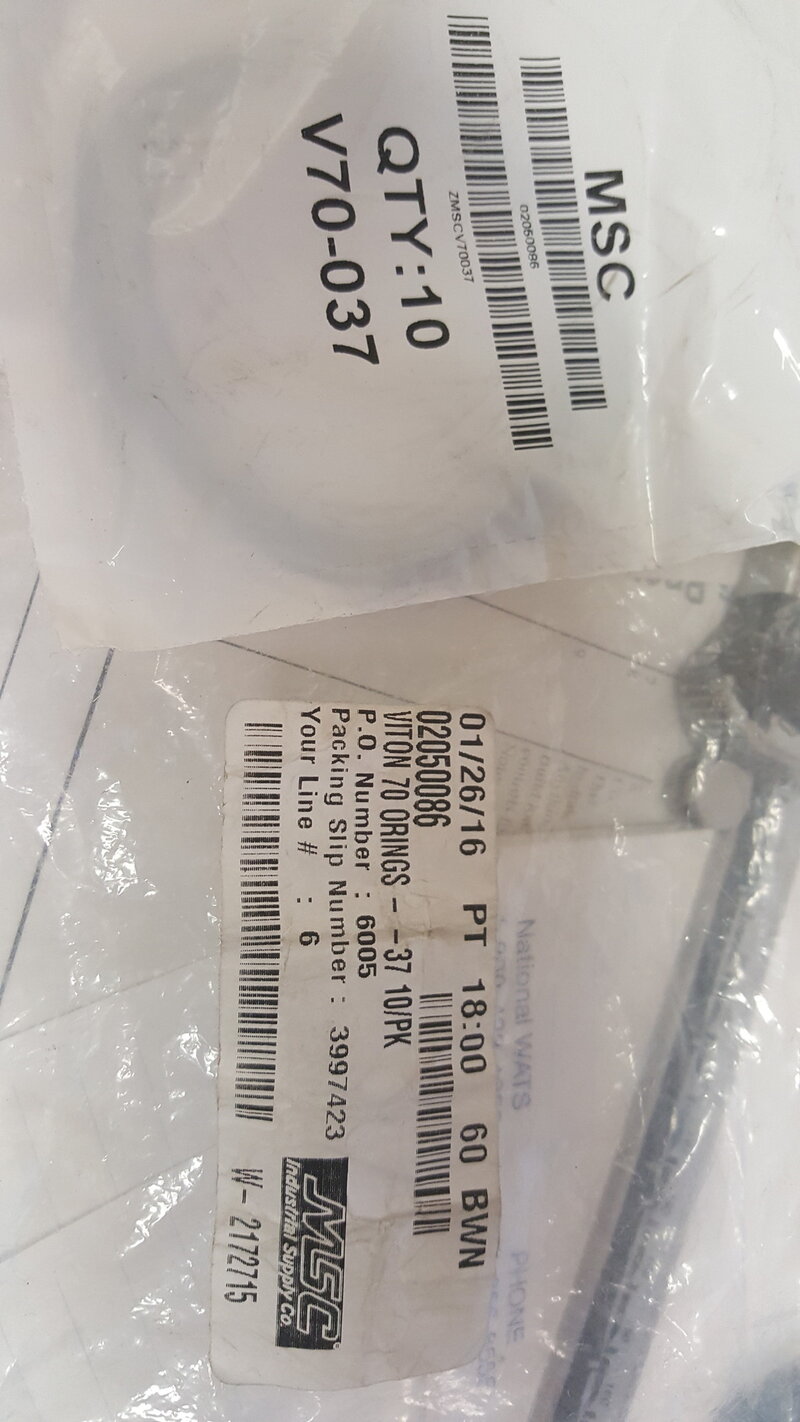

I am thinking o ring. Hence the chamfer.

I may have to put a groove under the bolt head.*

I still might find one that fits the chamfer only.

Trying to finish it up. Completing the machining of the smaller details.

Drill and tap to size.

For the oil thermo switch on the fan.

So it is nearly finished.

Finished the oil port through the bolt center.

Now to seal the bolt head to hole.

I am thinking o ring. Hence the chamfer.

I may have to put a groove under the bolt head.*

I still might find one that fits the chamfer only.