Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone else?

- Thread starter DeathBySnuSnu

- Start date

No but giving the 2.4 Ecotec 170 hp computer motor a lot of thought . $2200 plug and play straight to the door comes with everything I need .:Shrug:

Doug D.

"Tin Man"

Fuel who and curve what?? Dude, you just went way above my pay grade! I'm still settin' points!

Good luck and let us know how it turns out! I might even learn something! ThumbUp

Good luck and let us know how it turns out! I might even learn something! ThumbUp

- Thread starter

- #4

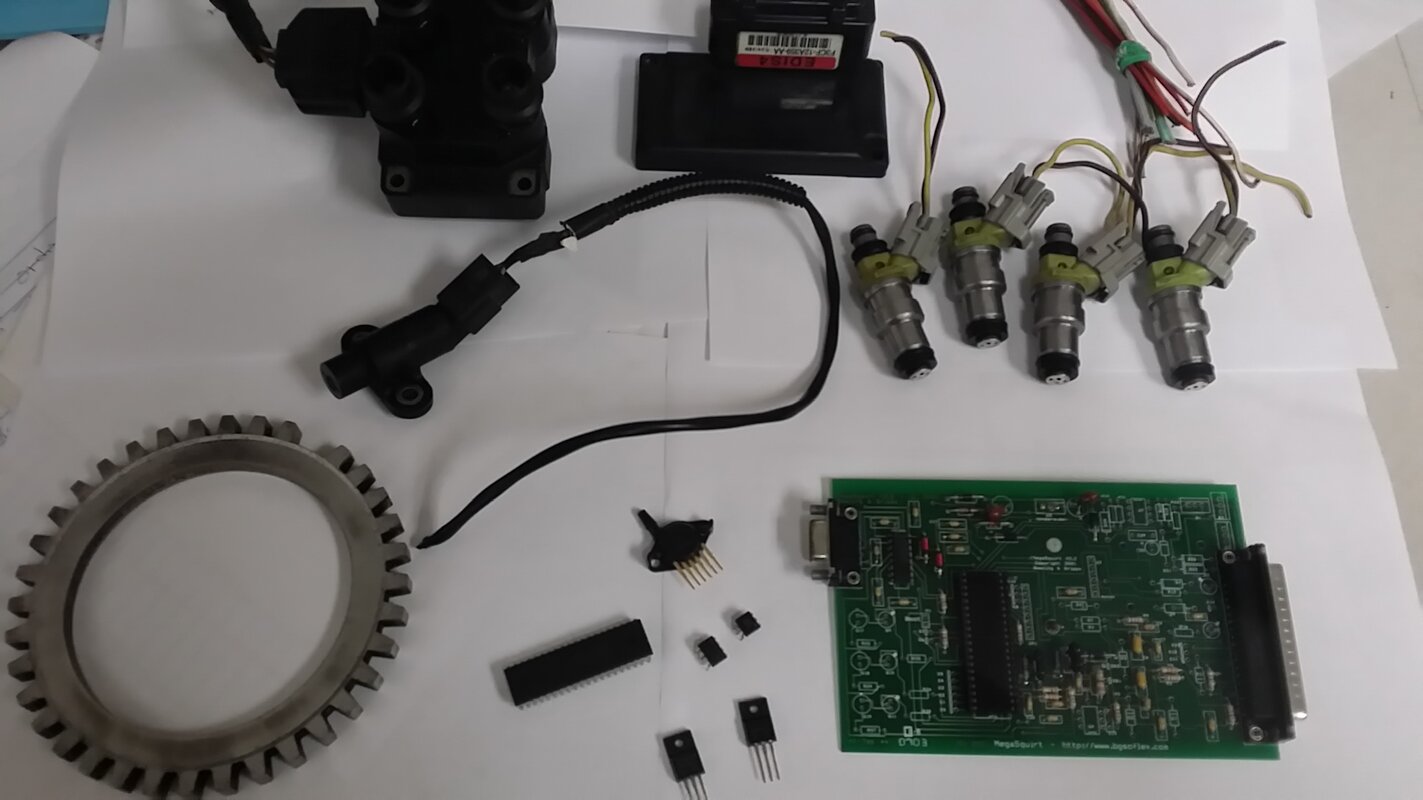

Well I have it apart.

Looks like it is gonna be a 2276cc or so.

I have ford edis coil driver and coil.

Crank trigger and wheel.

Mitshubishi high impedance 320 cc injectors.

Chevy sensors.

Camero throttle bodies that I ain't too sure about. Might do something else. Wanting to use a Ford idle air valve and it is pwm instead of the chevy stepper motor. The camero bodies have the idle air on the body themselves instead of seperate.

Currently building the controller board.

I have all the code to load on the chip and the software to set it.

Just need to figure out what to set it all to.

I have done stuff like this to other motors.

But not to an old air cooled vw.

I could just do enough math and make a guess and tune from there trial and error.

Or maybe I should get some wide band o2 sensors and just make it auto tune.

O well I will figure it out as I go.

Looks like it is gonna be a 2276cc or so.

I have ford edis coil driver and coil.

Crank trigger and wheel.

Mitshubishi high impedance 320 cc injectors.

Chevy sensors.

Camero throttle bodies that I ain't too sure about. Might do something else. Wanting to use a Ford idle air valve and it is pwm instead of the chevy stepper motor. The camero bodies have the idle air on the body themselves instead of seperate.

Currently building the controller board.

I have all the code to load on the chip and the software to set it.

Just need to figure out what to set it all to.

I have done stuff like this to other motors.

But not to an old air cooled vw.

I could just do enough math and make a guess and tune from there trial and error.

Or maybe I should get some wide band o2 sensors and just make it auto tune.

O well I will figure it out as I go.

good luck and let us know how it turns out.

all of the sensors , computers, and wiring night mares are why I retired my wrenches to my garage and went to nursing school.

all of the sensors , computers, and wiring night mares are why I retired my wrenches to my garage and went to nursing school.

- Thread starter

- #6

Last edited:

Doug D.

"Tin Man"

Damn... Now I want one!

WOW now I really feel OLD. I recently got a '71 single carb 1600 and I ain't used all it's got to offer. But I still remember when I would have wanted one. Boy Howdy, a 1000 miles and I would've been there in the morning. Gas, tires, and tickets. Sure did enjoy it. Which is part of the reason for my disability. But it was a hoot. Boy am I feeling old.

Thanks for your time and the memories.

Thanks for your time and the memories.

- Thread starter

- #9

Good luck and keep us updated .

- Thread starter

- #11

- Thread starter

- #12

- Thread starter

- #13

- Thread starter

- #14

- Thread starter

- #15

ThumbUp Very nice job !!!

ThumbUp

ThumbUp

- Thread starter

- #17

Thanks!

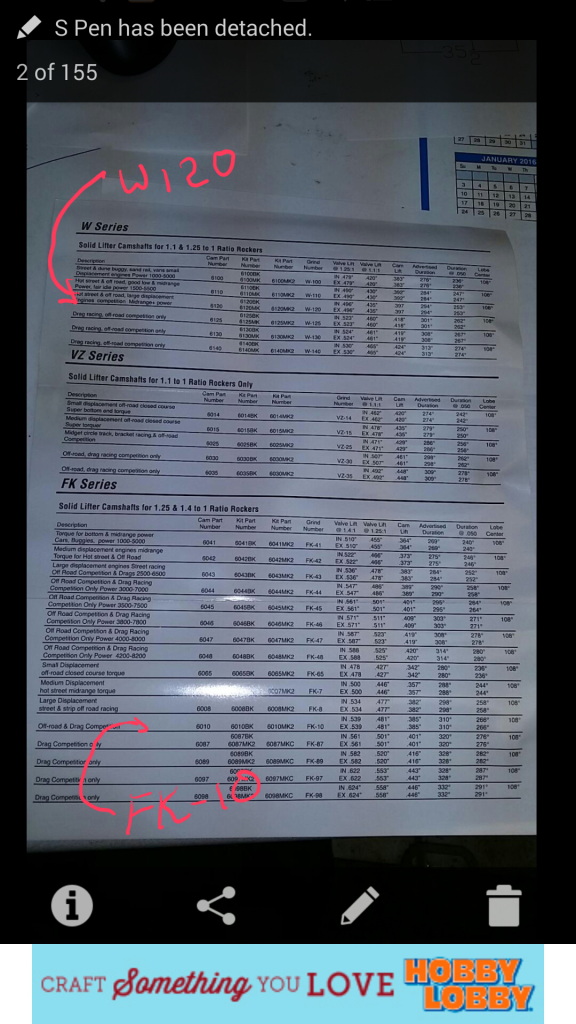

I have been emailing with Pat Downs.

I am going to be hard pressed to get to my 200 hp goal because of my 4 straights exhaust. He told me without a merged 4 into one collector I will not be able to run the big cam.

Did recommend a more aggressive cam than what I have now.

I am going to study it again. Maybe now I can figure out a place to put a real header.

I have been emailing with Pat Downs.

I am going to be hard pressed to get to my 200 hp goal because of my 4 straights exhaust. He told me without a merged 4 into one collector I will not be able to run the big cam.

Did recommend a more aggressive cam than what I have now.

I am going to study it again. Maybe now I can figure out a place to put a real header.

Good luck seems as though 4 into 1 riding that low with a mid engine is gonna be hard but I think if anybody can do it you will .

Now there is still the Ecotec 2.4 turbo 200 plus . LOL :Agree:

LOL :Agree:

Now there is still the Ecotec 2.4 turbo 200 plus .

Doug D.

"Tin Man"

Lookin' real sweet! Great job on those manifolds, I wish I had your shop!

- Thread starter

- #20

I went ahead and ordered 94mm pistons and cylinders. Also an Engle Fk10 cam.

New displacement. ........2387cc

Now to get back to working on it.

New displacement. ........2387cc

Now to get back to working on it.

Keep up posted Rex ,:clapping: get that thing going may have to go find Asian up in Oklahoma .

- Thread starter

- #22

- Thread starter

- #23

This is the upside down and backwards trans.

Normal 1 and 2.

Later style 1.26 3rd from us gear.

0.82 4th from rancho.

3.44 ring and pinion from rancho.

Welded on syncros.

Splined shafts.

Billit side plates

8 bolt carrier.

4 spider

Shortened axle

Disc brake conversion.

It is coming apart to check out any issues.

It has been gronking into 4th. Got to check the bearing adapter and nut at the end of the shaft by 4th. The Splined shafts are not supposed to fit a swing so it has adapters to match the different bearing sizes. My adapters leave no place for the lock tab washers. I suspect a loosened nut. I may have to tack weld the nut.

- - - Updated - - -

Drive extension.

The bearing in this runs on grease from a remote nipple.

Gotta check that too.

Feels fine from the outside.

I have not torn these down yet.

My pile is large enough already

- - - Updated - - -

Building a fuel injection and ignition controller.

- - - Updated - - -

Whittling on the cases.

Making room for more bore and more stroke.

- - - Updated - - -

Stainless steel rockers.

Did not go with the pistol shapes just did not seem to go with my style.

- - - Updated - - -

Fork legs did not come out as expected.

Would not stay straight enough for me.

Here they are in the scrap bin.

Starting over with solid bar.

Normal 1 and 2.

Later style 1.26 3rd from us gear.

0.82 4th from rancho.

3.44 ring and pinion from rancho.

Welded on syncros.

Splined shafts.

Billit side plates

8 bolt carrier.

4 spider

Shortened axle

Disc brake conversion.

It is coming apart to check out any issues.

It has been gronking into 4th. Got to check the bearing adapter and nut at the end of the shaft by 4th. The Splined shafts are not supposed to fit a swing so it has adapters to match the different bearing sizes. My adapters leave no place for the lock tab washers. I suspect a loosened nut. I may have to tack weld the nut.

- - - Updated - - -

Drive extension.

The bearing in this runs on grease from a remote nipple.

Gotta check that too.

Feels fine from the outside.

I have not torn these down yet.

My pile is large enough already

- - - Updated - - -

Building a fuel injection and ignition controller.

- - - Updated - - -

Whittling on the cases.

Making room for more bore and more stroke.

- - - Updated - - -

Stainless steel rockers.

Did not go with the pistol shapes just did not seem to go with my style.

- - - Updated - - -

Fork legs did not come out as expected.

Would not stay straight enough for me.

Here they are in the scrap bin.

Starting over with solid bar.

- Thread starter

- #24

- Thread starter

- #25

Keep up posted Rex ,:clapping: get that thing going may have to go find Asian up in Oklahoma .

Already took three hands and the "pucker method" to stay with it to start with.

I call myself putting enough duration on the cam that I soften up the bottom end. So maybe just normal putt around riding it won't even be on the cam at all.

Putt around sub 3500 at an off the cam 50hp. Then twist on it and in comes the cam at 200 hp all the way to 7500rpm.

The old motor came on pretty low and was "twitchy" to ride sometimes. Fun but scary at times in traffic. I have had a few panic "get on the brake- get the front on the ground- before I run into someone" moments.

- Thread starter

- #26

- Thread starter

- #27

I am curious about the process of building a front engine VW trike. It seems I've heard it takes two tranaxles, one flipped upside down as yours is. I have old transaxles around and who knows, maybe someday I would attempt a front engine build. Looks interesting. Thanks.

- Thread starter

- #29

It takes internal machine work inside the case to make it oil.

Rancho will build you an inverted. They are the only ones I know of.

I have full access to a machine shop. So it does not bother me to do heavy modifications.

The normal way to do it is to pull the ring and carrier out one side of the case and stick it in the other. All then is shimming the backlash. No machine work.

I flipped the entire trans to make mine much lower than the car would be.

If you use a full width irs you could squat it down fairly low. If you narrow it then no.

If you want to run a swing then no again.

Bad ass trike company sells frames and drive components for a normal set up.

But mine is 6 inches lower than normal.....lol

- - - Updated - - -

This is what it looked like before I took it apart.

Drain plug is 3-1/2" off the ground unloaded.

Rancho will build you an inverted. They are the only ones I know of.

I have full access to a machine shop. So it does not bother me to do heavy modifications.

The normal way to do it is to pull the ring and carrier out one side of the case and stick it in the other. All then is shimming the backlash. No machine work.

I flipped the entire trans to make mine much lower than the car would be.

If you use a full width irs you could squat it down fairly low. If you narrow it then no.

If you want to run a swing then no again.

Bad ass trike company sells frames and drive components for a normal set up.

But mine is 6 inches lower than normal.....lol

- - - Updated - - -

This is what it looked like before I took it apart.

Drain plug is 3-1/2" off the ground unloaded.

Definitely one of the meanest looking trikes around. I don't have access to a machine shop so is it possible to do this without machine work? Uh oh, looks like I may be researching another project.:laugh:

Similar threads

- Replies

- 6

- Views

- 760

- Replies

- 6

- Views

- 5,914

- Replies

- 4

- Views

- 8,807

- Replies

- 6

- Views

- 16,211

- Replies

- 3

- Views

- 12,010

- Replies

- 2

- Views

- 8,613