Jack Klarich

Guest

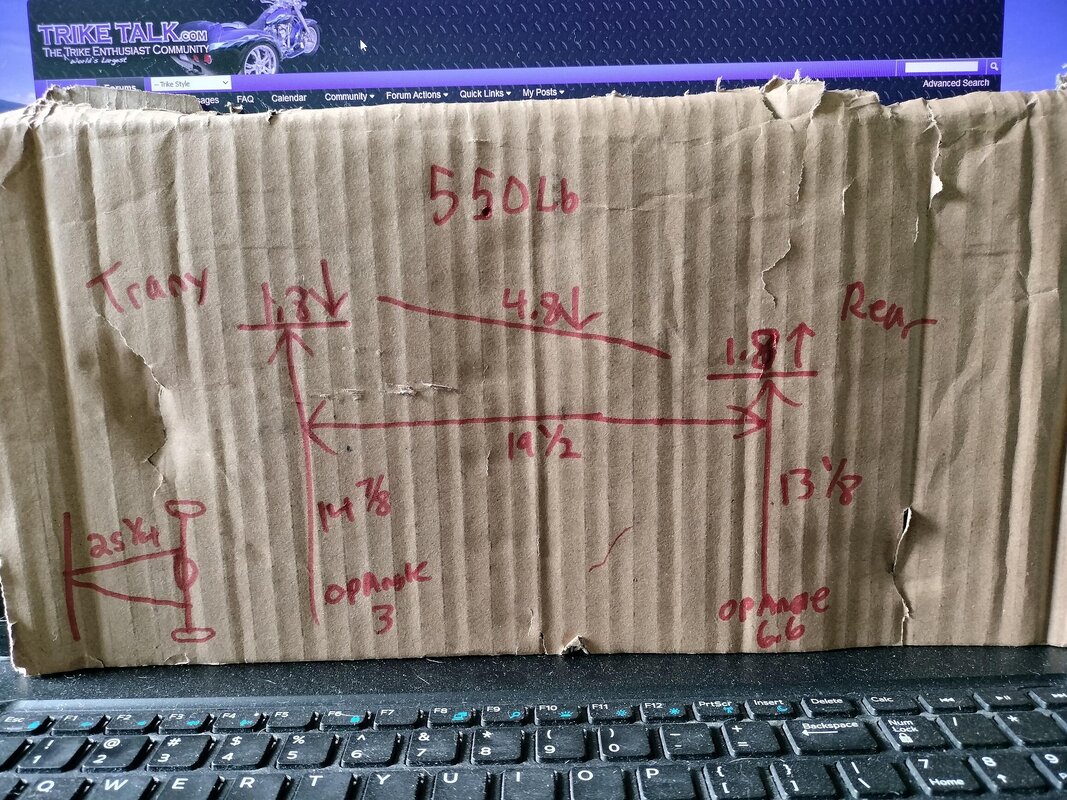

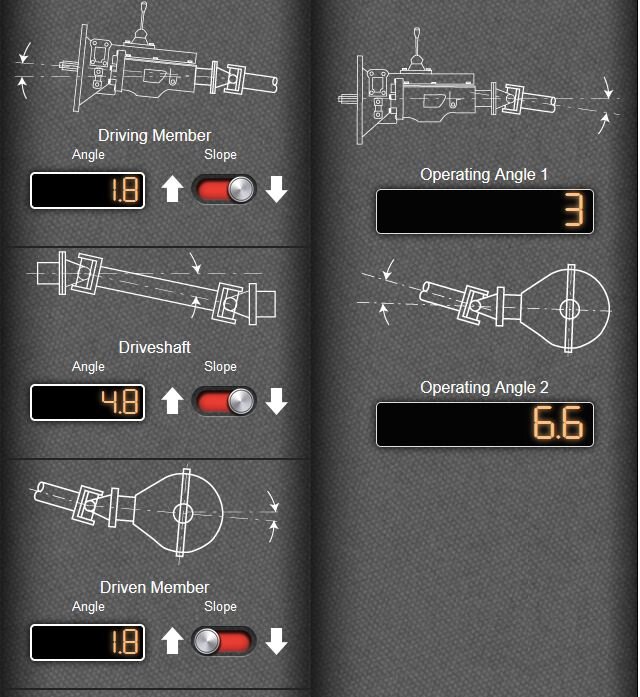

linkage at booster not depressed and depressed. I need to move the rod in the first pic to the right side of the linkage. I did not notice that until I looked at the PIC

View attachment 115772 View attachment 115773

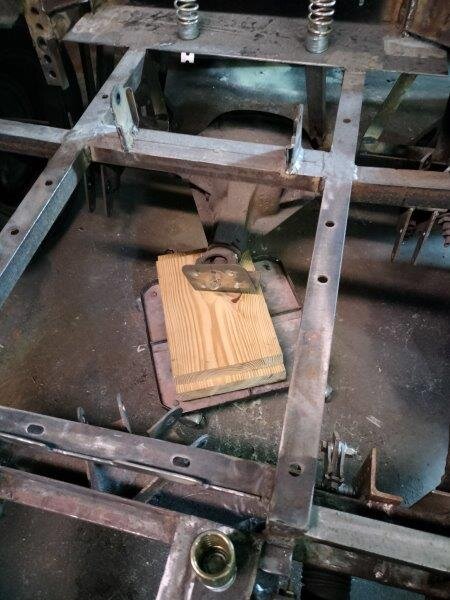

Added a support for my seat bracket. Not finished yet. I can remove the master cyl still with this brace. The problem is now I have to redo the brace on the other side sine its not at the same angle.

View attachment 115774

Mocking up all the geometry is time consuming but your finished project will be worth it