Fowler

◇BUILD IT BOB◇

- Thread starter

- #601

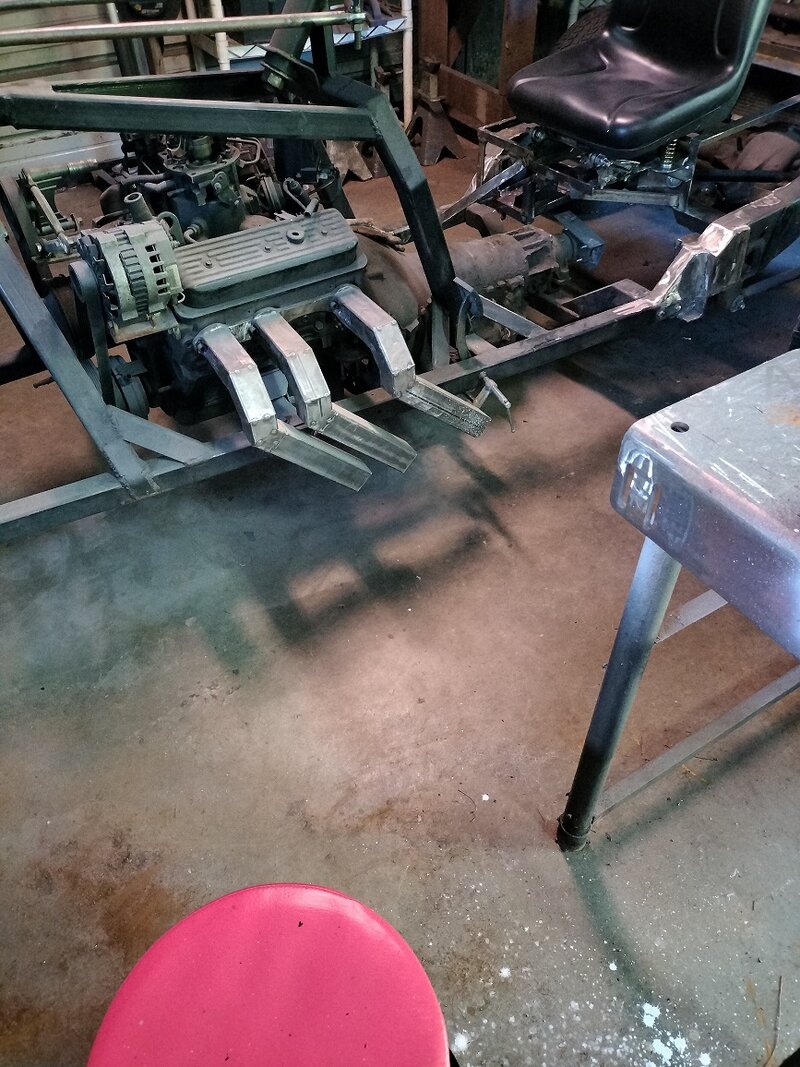

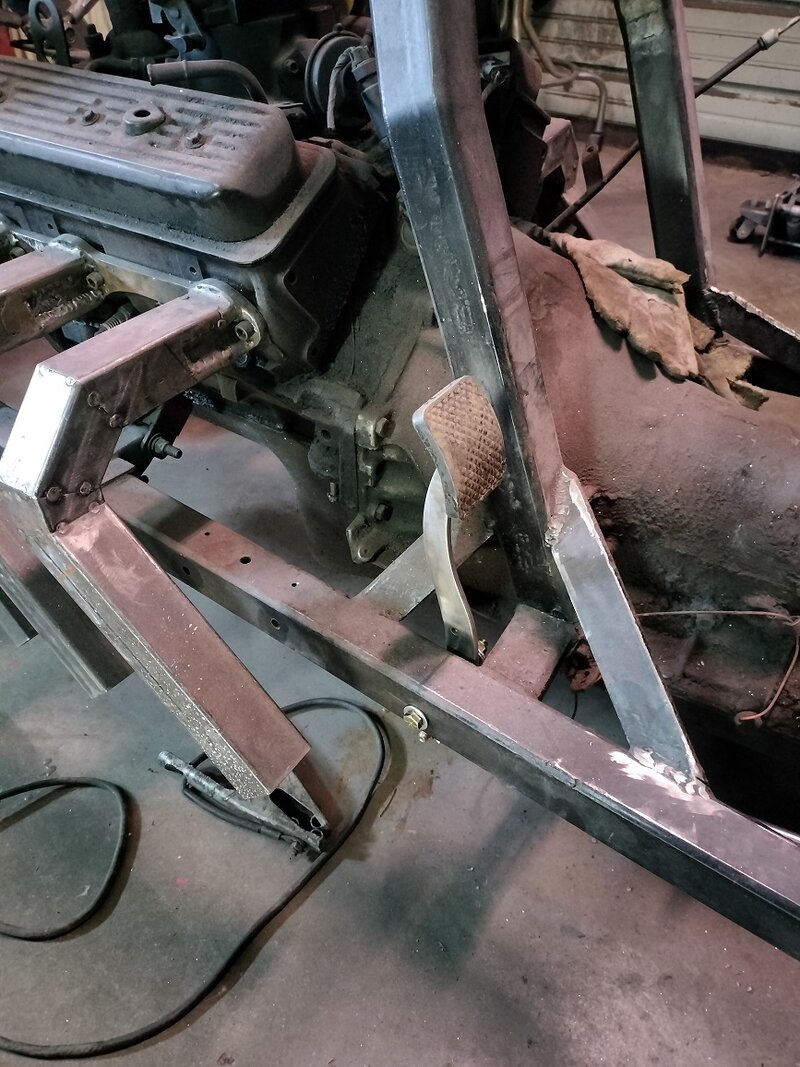

Did some more work on the battery box and seat frame area. Had to wait for some sanding disk to come in. For some reason I cant find any disk for my die grinder here locally.

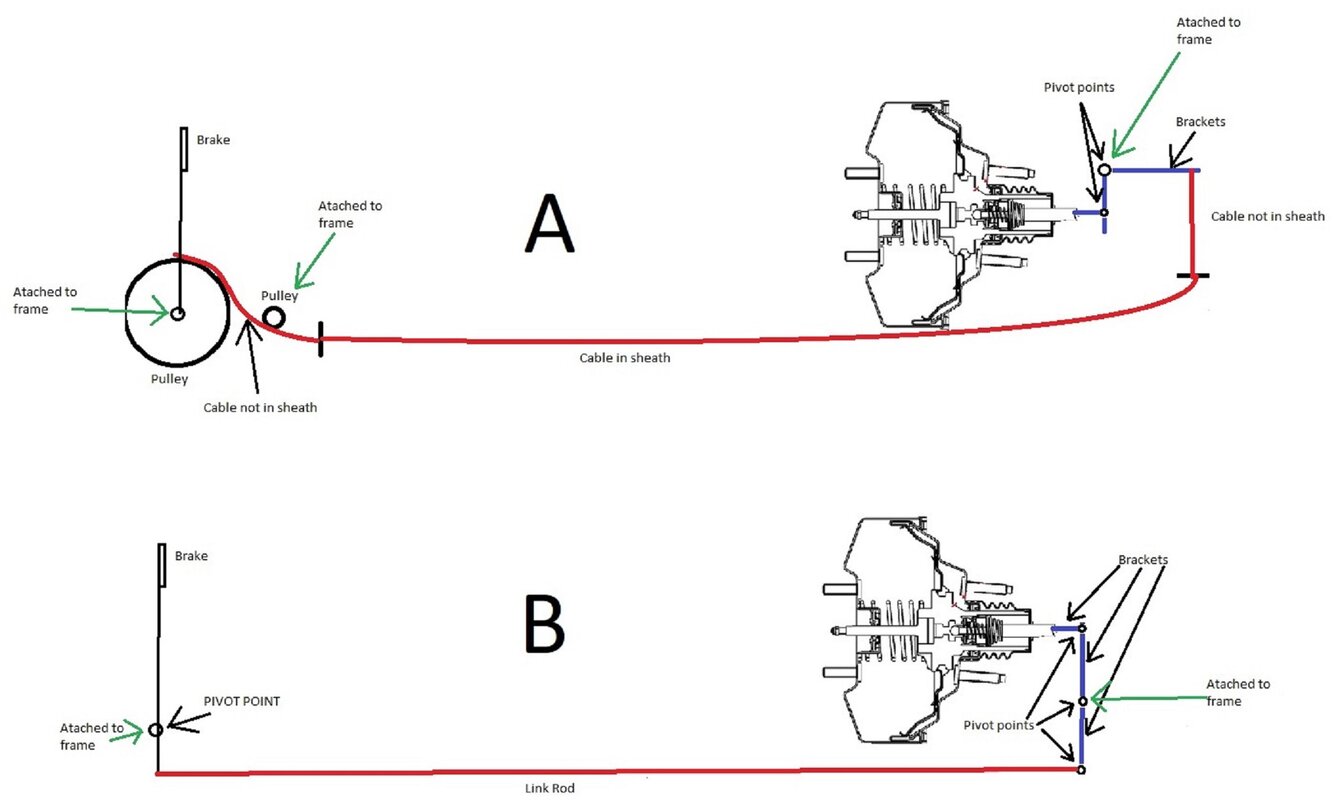

I think my son got me a brake booster and master cylinder for my birthday coming up

I will have to mount it under the floor and most likely backward

Once I have it I will figure out the left side of the seat area

I think my son got me a brake booster and master cylinder for my birthday coming up

I will have to mount it under the floor and most likely backward

Once I have it I will figure out the left side of the seat area