LarryA

500+ Posts

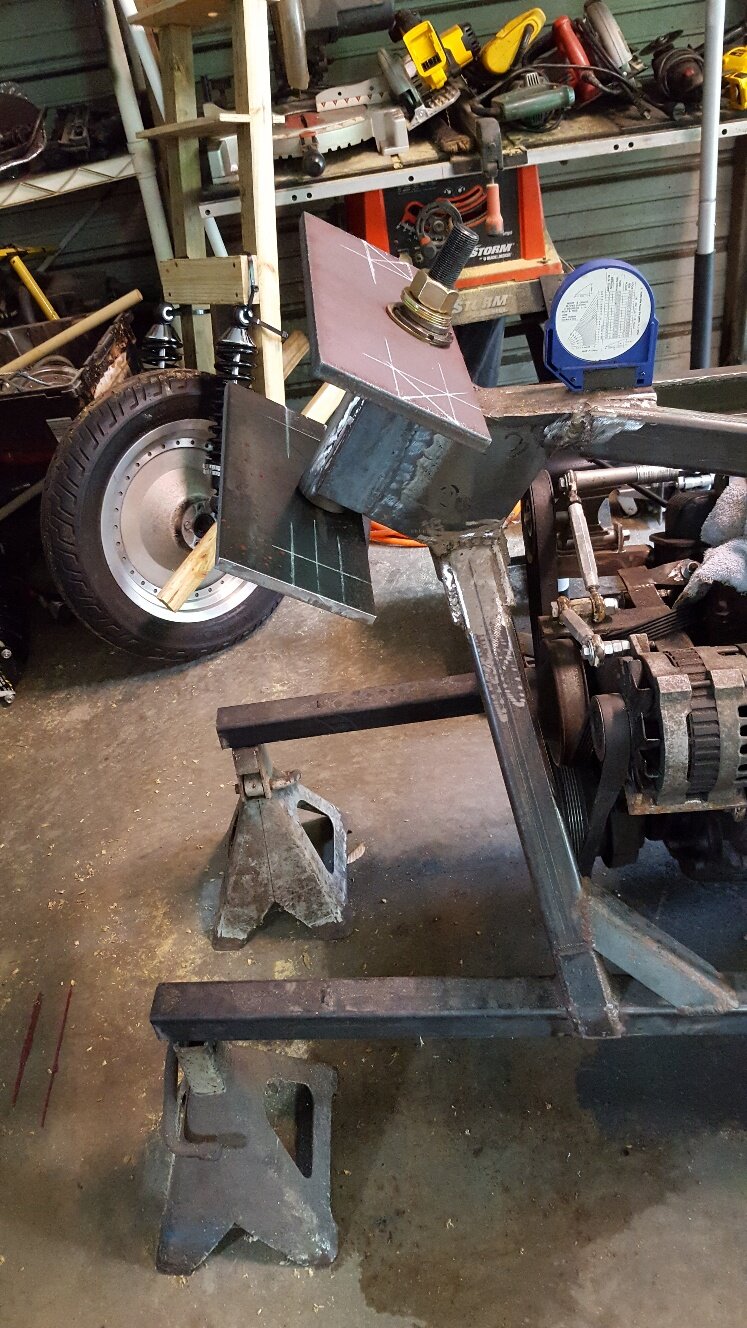

stacebg....I would agree with that statement. The wraparound does indeed give the superior ridgidity to the leading link!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

stacebg....I would agree with that statement. The wraparound does indeed give the superior ridgidity to the leading link!

just a question....what angle will your rockers be when full load is on your front end? Just my opinion, I like them tilted upward slightly at the forward end. Also what material will you use for the bail....or wraparound, as some may call it? I just used the same mtl. as the rockers. But it can twist, so I wish I had used round tubing like Stacybg used on his front.

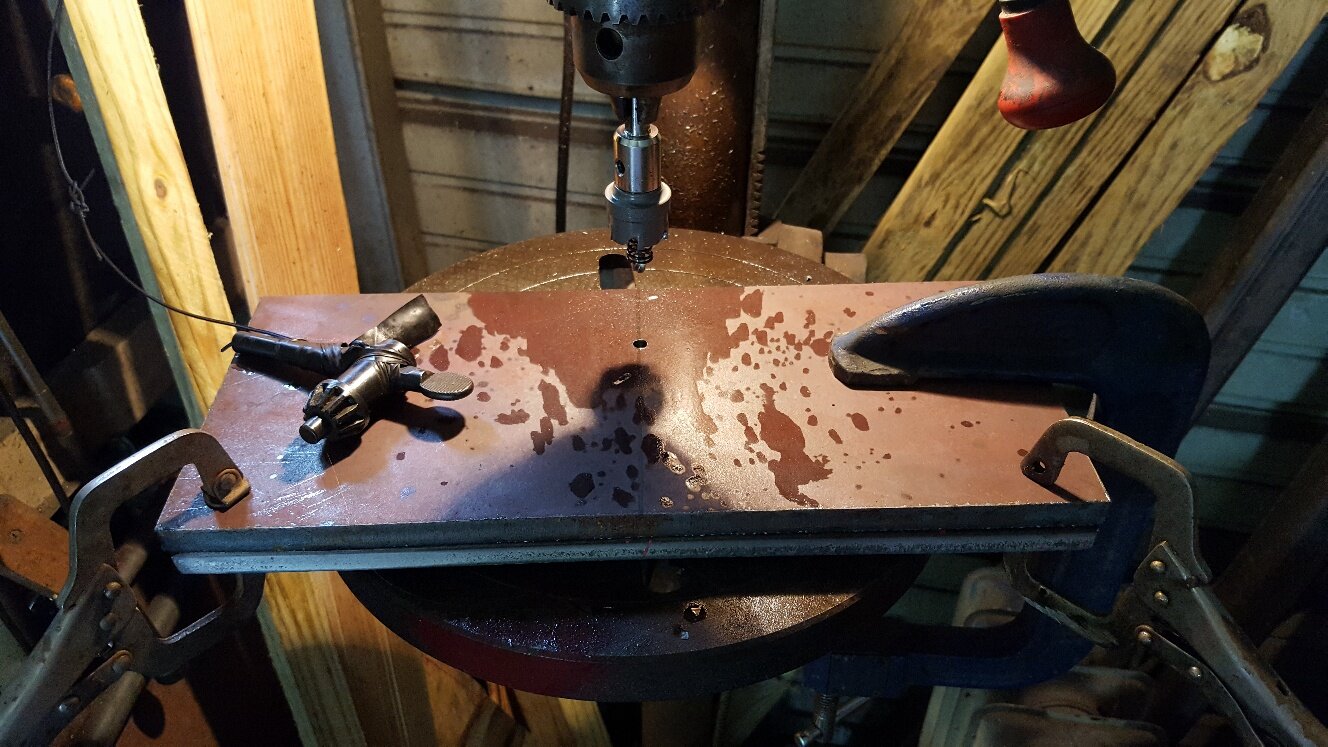

I would think that you would have better luck with a new hole saw, slow speed, and lots of lubricant. Less likely to grab a flute and launch your piece. If the 3/4 holes in the 2" tubing are for pivots, axle, etc. consider using a sleeve to provide more load bearing surface. https://www.ebay.com/itm/Steel-Tubi...R40&rt=nc&_trksid=m570.l1313&LH_TitleDesc=0|0

With this you could just drill 1" holes in the tubing, align the bushings, and weld in place. This process could compensate for any "drift" in the drilling process.

OK I will plan on having the pivot point lower as you guys suggested

I just received my 1" hole saw in today It came real quick

I'm debating if I want to make the forks wider. I have 1 inch clearance between the tire and the side of the fork but I have to mount my shocks a little off center of the rockers and down tubes to keep that 1 inch clearance

If I decide to go wider it will delay things. I have the money to buy more plate steel but don't have the time to go get it.

Im sucking up to the Ol'Lady now in case I need her to go get it

didnt notice what u got the hole saw for but.. it will not make a very tight tolerance hole... it will be quite a bit over

I need to be able to get something from the local hardware store, Lowes, Ace someplace like that

Well that sucks...

I was planning to use it for the neck stem holes in the upper and lower plate and the hold in the rockers for the axle. The axle is 3/4 but I am using a 1" spacer that reduces it down to 3/4"

I will have some extra plate steel and will drill a test hold in it first

Question???

what lubricant should I use when drilling these hole?

I need to be able to get something from the local hardware store, Lowes, Ace someplace like that