Fowler

◇BUILD IT BOB◇

- Thread starter

- #421

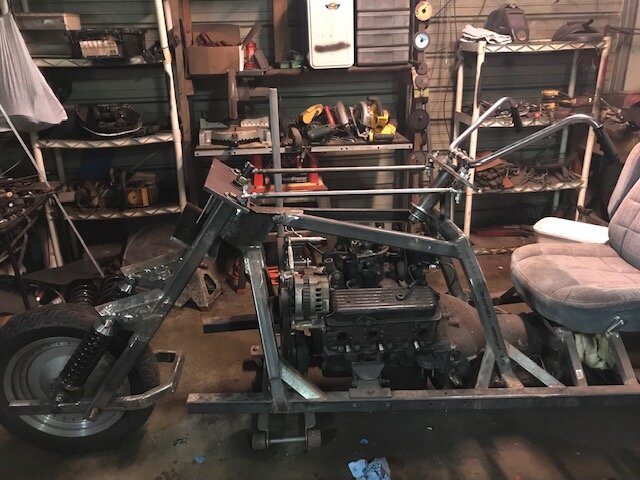

Got the neck tack welded in place. I may have to change the height and angle

My measurements are not correct though.

I'm off by 1/4 inch

I was figuring that out but had to stop to do a wheel bearing job on the front of my kids truck.

Hey just told me about it today, The outer bearing on 1 side was in bad shape

Then had to setup for Boxing night. (changed to Saturday this week)

Tomorrow if I do not have to bad of a hangover I will look at the alignment again.

I plan to connect to the top of the front plate and the bottom of the back plate

My measurements are not correct though.

I'm off by 1/4 inch

I was figuring that out but had to stop to do a wheel bearing job on the front of my kids truck.

Hey just told me about it today, The outer bearing on 1 side was in bad shape

Then had to setup for Boxing night. (changed to Saturday this week)

Tomorrow if I do not have to bad of a hangover I will look at the alignment again.

I plan to connect to the top of the front plate and the bottom of the back plate