- Thread starter

- #181

yes, that does look nice, still might need it of all goes wrong for me.

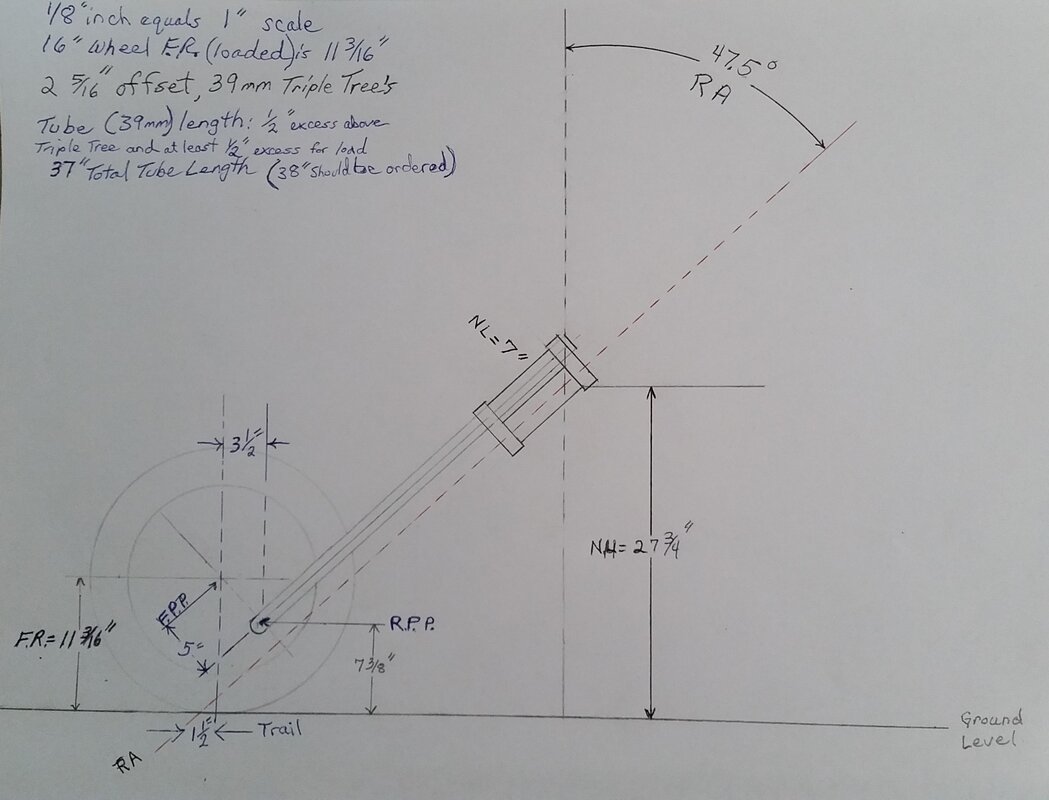

I have to much time on my hands at times, so not a problem and I need to see what I could do, first time for this work.

I have to much time on my hands at times, so not a problem and I need to see what I could do, first time for this work.