- Thread starter

- #361

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone else?

- Thread starter DeathBySnuSnu

- Start date

- Thread starter

- #362

- Thread starter

- #363

The head studs are switched out and fit a lot better. All the nuts on and heads snugged down but not torqued to spec.

Measured on the rocker geometry some and not too far out. Gotta make some thin shims .050" thick.

Still looks the same.

Measured on the rocker geometry some and not too far out. Gotta make some thin shims .050" thick.

Still looks the same.

- Thread starter

- #364

- Thread starter

- #365

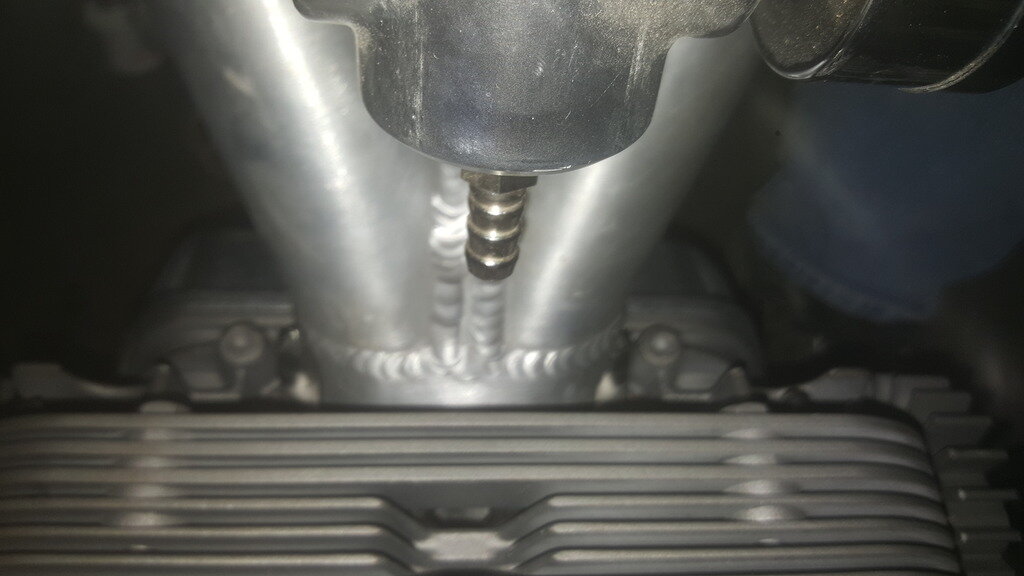

Looking at what to do with this.

Has drug the ground more than once.

A couple of the studs were broken also at one time.

Thinking of making a thicker plate with no drain plug in the bottom. With the nuts counter sunk so deep that they dont stick out and with the drain hole on the side of the thicker plate

Ahhh the low life......

Has drug the ground more than once.

A couple of the studs were broken also at one time.

Thinking of making a thicker plate with no drain plug in the bottom. With the nuts counter sunk so deep that they dont stick out and with the drain hole on the side of the thicker plate

Ahhh the low life......

vwbug72501

700+ Posts

Wouldn't a thicker plate end up just providing a larger scrub surface? I would think that a plate thick enough to allow a side mounted drain would extend down at least as far as the existing (scrubbed) drain bolt head. Also, is smacking the bottom of a high dollar engine case a good idea? Maybe a frame mounted skid plate or skid bar(s) might be a better idea. Just my 2 cents.

I was wondering how that would drag so bad until I zoomed in on your front mounted engine, yep it's low. My opinion would be keep using as is, use loc nuts instead of long cap nuts. It's so low no one will see it. Nice wide tires & wheels would really make that trike look good and still have plenty power, 2cents.

If it wasn't for that one rogue stud that holds the pickup tube you could use a flat plate with counter sunk bolts. Honda had counter sunk bolts little groove where the head meets the base for a oring. Then just eliminate the plug you don't need it anyway.

peteg59

Meme Master

Not many viable options other than raising the ride height. Perhaps going back to a "stock" oil strainer cover plate in steel, without a drain bolt?

Is it currently too low to install an expanded metal skid plate on the frame, of some sort?

Is it currently too low to install an expanded metal skid plate on the frame, of some sort?

- Thread starter

- #370

Thanks for the input guys.

I am not that worried that it has scrubbed.

More worried about that rare occasion it gets drug over a speed bump....that it could get unscrewed.

I rubbed a big block on the ground once and spun the plug right out of it and dumped the oil out right there.

With the trans upside-down the engine is 6 inches lower that it would be stock. I did it this way for looks and I like it.

It seemed a better idea to have the thicker plate. If it ever got drug would be no plug to get unscrewed.

With the new fork and new rear tires I could be as much as a half inch taller now.

I am just gonna hafta try harder to not put it in those spots it could drag.

One is the speed bump at the high school (I have kids to fetch there). Maybe just not take the scooter there, no going around that one.

The other is the curb at wal mart. No motorcycle parking here. The police let bikes park on yhe sidewalk. The curb at my wal mart is taller than normal. It take a little snap and twitch to wheelie hop the front up on it. Normally could hop on and off without dragging. But it has been drug there.

I suppose I shouldnt park on that sidewalk there anymore.

So it dont just simply drag all over the place. I can avoid most of it. But one day it will wind up getting drug over the speed bump at the high school again. That happens unplanned at times.

Maybe a flatter plate and drain out somewhere else....

I am not that worried that it has scrubbed.

More worried about that rare occasion it gets drug over a speed bump....that it could get unscrewed.

I rubbed a big block on the ground once and spun the plug right out of it and dumped the oil out right there.

With the trans upside-down the engine is 6 inches lower that it would be stock. I did it this way for looks and I like it.

It seemed a better idea to have the thicker plate. If it ever got drug would be no plug to get unscrewed.

With the new fork and new rear tires I could be as much as a half inch taller now.

I am just gonna hafta try harder to not put it in those spots it could drag.

One is the speed bump at the high school (I have kids to fetch there). Maybe just not take the scooter there, no going around that one.

The other is the curb at wal mart. No motorcycle parking here. The police let bikes park on yhe sidewalk. The curb at my wal mart is taller than normal. It take a little snap and twitch to wheelie hop the front up on it. Normally could hop on and off without dragging. But it has been drug there.

I suppose I shouldnt park on that sidewalk there anymore.

So it dont just simply drag all over the place. I can avoid most of it. But one day it will wind up getting drug over the speed bump at the high school again. That happens unplanned at times.

Maybe a flatter plate and drain out somewhere else....

"I rubbed a big block on the ground once and spun the plug right out of it and dumped the oil out right there" :xzqxz:

Dang, you're a great awesome mechanic, just need driving lessons, lol.

I'd have to agree with the thicker plate with side drain since you have more clearance now.

Dang, you're a great awesome mechanic, just need driving lessons, lol.

I'd have to agree with the thicker plate with side drain since you have more clearance now.

- Thread starter

- #372

- Thread starter

- #373

- Thread starter

- #374

Well....my camera is cracked on my phone. My pics are now blurry junk. I dunno when I will get to replace my phone. Everything I do on the internet is done with my phone.

Once the intakes were tight I then started on the throttle cables.

I pick stuff up off ebay just here and there.

I have one Venhill cable kit and one generic cable kit. The generic one is junk compared to yhe Venhill.

I suppose I have gotta find and get another venhill kit from across the big pond.

Once the intakes were tight I then started on the throttle cables.

I pick stuff up off ebay just here and there.

I have one Venhill cable kit and one generic cable kit. The generic one is junk compared to yhe Venhill.

I suppose I have gotta find and get another venhill kit from across the big pond.

- Thread starter

- #375

I did make up the primary throttle cable.

Soldering ends on.

And the assembled single pull throttle.

It is on the scooter and works slick.

Those Venhill cables are good stuff and come with several styles of solder on ends.

I ordered another for the cross over cable. Not going to use the shabby generic cable kit.

Soldering ends on.

And the assembled single pull throttle.

It is on the scooter and works slick.

Those Venhill cables are good stuff and come with several styles of solder on ends.

I ordered another for the cross over cable. Not going to use the shabby generic cable kit.

- Thread starter

- #376

Working on the ss braid hoses.

Most of them made up now.

Did you use all Russel fittings and hoses Rex?

- Thread starter

- #378

Not all.

Most of the fittings are Not name brand stuff.

If you look closely at Russell or airoquip their fittings have real anodizing on them. The color is part of the metal.

That is what the big difference is in the no name stuff. Not real anodizing. Just painted color to look like it.

Some of the no name stuff is not speced or even sold correctly. So make sure what you get actually fits together correctly and tight.

See how bad it scratches up.

Most of the fittings are Not name brand stuff.

If you look closely at Russell or airoquip their fittings have real anodizing on them. The color is part of the metal.

That is what the big difference is in the no name stuff. Not real anodizing. Just painted color to look like it.

Some of the no name stuff is not speced or even sold correctly. So make sure what you get actually fits together correctly and tight.

See how bad it scratches up.

- Thread starter

- #379

- Thread starter

- #380

I like circuit breakers cheap easy to hook up and come auto reset or manual.

- Thread starter

- #382

I didn't find one for the amperage.

This is the fuse link.

I have a full fuse box, this is for the primary wire for the fuse box. I dont have much space left.

This is the fuse link.

I have a full fuse box, this is for the primary wire for the fuse box. I dont have much space left.

So I see you're just gonna bolt that to the battery terminal then the main wire gets bolted to the fuse.

- Thread starter

- #384

Yes basically.....

But on the starter lug, as it is next to the fuse box.

But on the starter lug, as it is next to the fuse box.

When I look at the distance between the lug and the fuse box it seems almost impossible to get a short on that wire. The fuses will handle anyting on the other side. New cars have fusable links for catastrophic failure maybe fit a little better in your application?

- Thread starter

- #386

Yes it is for catastrophic failure of all my pieced together fuel injection.

The motorcyle part is seperate.

If I caint get this to work out then I will hunt for something else.

Yes I have been hunting some kind of fuse link that will fit in the area I have to work with.

Not to sure how this one will work out.

But it is small. Now to figure it out or get something else.

Do you know where to find a small but 50a fuse link? I have found some but with no amp rating. Nothing but the auto application listed

The motorcyle part is seperate.

If I caint get this to work out then I will hunt for something else.

Yes I have been hunting some kind of fuse link that will fit in the area I have to work with.

Not to sure how this one will work out.

But it is small. Now to figure it out or get something else.

Do you know where to find a small but 50a fuse link? I have found some but with no amp rating. Nothing but the auto application listed

Well my understanding is fusable link wire is usually four sizes under the wire you're running, so 10 gauge wire 14 gauge link. I don't know what your set up is but the highest draw should be the fuel pump, nothing else should be close to that. 50 amps is a lot,ecm usually have a ten amp fuse. Those systems run off 5 volts. None of the wires I see going into that fuse box could support 50 amp.

- Thread starter

- #388

Only the one primary wire into box is 50 amp.

If you add up full load of engine parts, fuel pump, coil, idle air valve, injectors and the low loads, ecm, sensors, it all is 60 amps total.

But that is everything at full load at the same time. I dont think that will actually happen.

So I went 50 amps on the primary side and that is all the load the motorcycle fuse box will handle anyway.

If you add up full load of engine parts, fuel pump, coil, idle air valve, injectors and the low loads, ecm, sensors, it all is 60 amps total.

But that is everything at full load at the same time. I dont think that will actually happen.

So I went 50 amps on the primary side and that is all the load the motorcycle fuse box will handle anyway.

I'm not there so I don't know that seems high to me,but you're correct that scenario will never happen. So everything is fused in that box so no matter what happens a fuse will blow. The only way I can see shorting out would be the back of the fuse box somehow grounding out. To me it looks like it can only burn that 6 inch wire. The only real difference between a fuse link wire and a regular wire is the link wire has insulation that doesn't burn.

- Thread starter

- #390

One other thing. The plus side power is always on. All the switching and controlls are npn sinking. I even converted the switches on the bars. So everything is controlled on the negative side. So grounding it turns it on. Everthing is plus hot all the time instead of grounded all the time.

It started with the kit computer, it sinks to ground, so that type of control got used on everything else.

It started with the kit computer, it sinks to ground, so that type of control got used on everything else.

Similar threads

- Replies

- 6

- Views

- 837

- Replies

- 6

- Views

- 5,978

- Replies

- 4

- Views

- 8,856

- Replies

- 6

- Views

- 16,256

- Replies

- 3

- Views

- 12,053

- Replies

- 2

- Views

- 8,644