- Thread starter

- #61

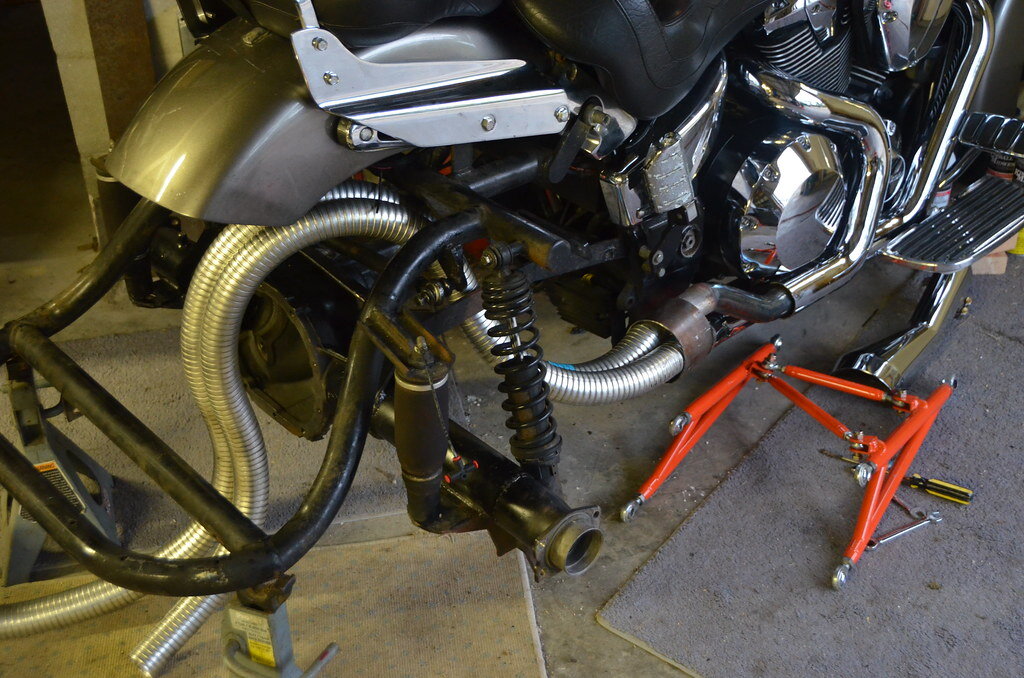

WOW. Like Holy Flurkin Schmidt WOW.

Dry braking with the race tire is what i wanted. Mrs V said it was easily twice the stopping force, and I was being cautious testing with a passenger.

I warned her, it was a declared test, but she was still squished to the 'cant breathe' point and I still had not locked the tires. :clapping:

WORTH*EVERY*PENNY

First fill up since running out of gas, 3.32 gallons did 101 miles. 33mpg

GLEE ON THREE!!!

Dry braking with the race tire is what i wanted. Mrs V said it was easily twice the stopping force, and I was being cautious testing with a passenger.

I warned her, it was a declared test, but she was still squished to the 'cant breathe' point and I still had not locked the tires. :clapping:

WORTH*EVERY*PENNY

First fill up since running out of gas, 3.32 gallons did 101 miles. 33mpg

GLEE ON THREE!!!