Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebel RT

- Thread starter TomyJ

- Start date

That looks great, glad you found it, getting it done!

- Thread starter

- #69

- Thread starter

- #72

RebelRouser

Thank You, I look at that single rear tire as we would a trike with 2 tires, 2 6" wide tires on the ground equal 12" of traction, You/We know there will be a time or two when we have to SLAM on the brakes and pray we stop short of the problem, damn I hate saying that...

Thank You, I look at that single rear tire as we would a trike with 2 tires, 2 6" wide tires on the ground equal 12" of traction, You/We know there will be a time or two when we have to SLAM on the brakes and pray we stop short of the problem, damn I hate saying that...

The control arm lower brackets, tabs and gussets are 3/16, I hope overkill? I should have made some fixture bushings .005-.010 over and bolted before welding, I will for the upper ones...View attachment 64040

what i do is put one or two pc of manila folder in there then u dont have to fart around w making bushings... with that setup i bet it will pull enough to get the a arm back in.... if it werent for the rubber i would weld it up solid as is yes a tad overkill.... my moto.... build it strong

u wont go wrong.... unless u are racing then u have to draw the line some place

- Thread starter

- #75

RebelRouser

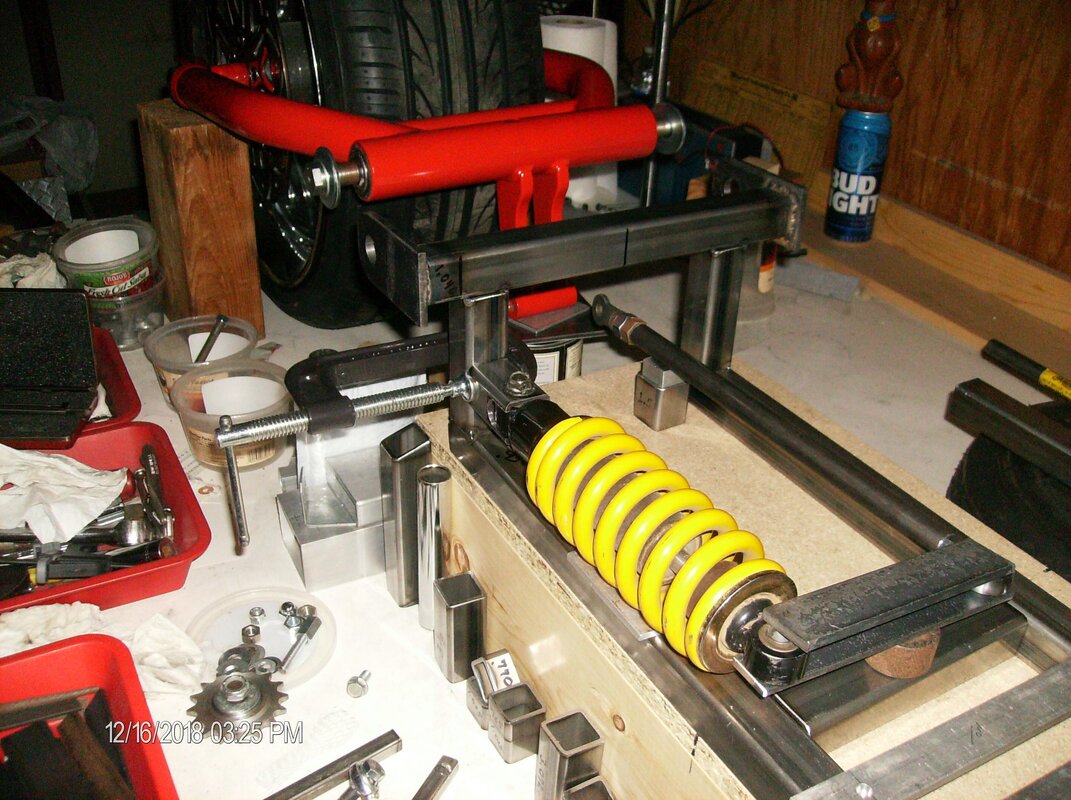

Upper frame rails are being dialed in for jack shaft and engine clearance...

This is going to take some time and many headaches? Back to flatness problems again with 60 degree bends or cuts? Ordered a flat 46T Harley painted sprocket, I will counter sink the mounting bolts for a closer fit to the swing arm. Tomorrow is Thanksgiving holiday weekend and wife is out of the country with relatives SOOOOOOO!!! Home alone and many drawings and glasses of red wine,

ME2

ME2

Upper frame rails are being dialed in for jack shaft and engine clearance...

This is going to take some time and many headaches? Back to flatness problems again with 60 degree bends or cuts? Ordered a flat 46T Harley painted sprocket, I will counter sink the mounting bolts for a closer fit to the swing arm. Tomorrow is Thanksgiving holiday weekend and wife is out of the country with relatives SOOOOOOO!!! Home alone and many drawings and glasses of red wine,

ME2

ME2- Thread starter

- #76

- Thread starter

- #77

RebelRouser

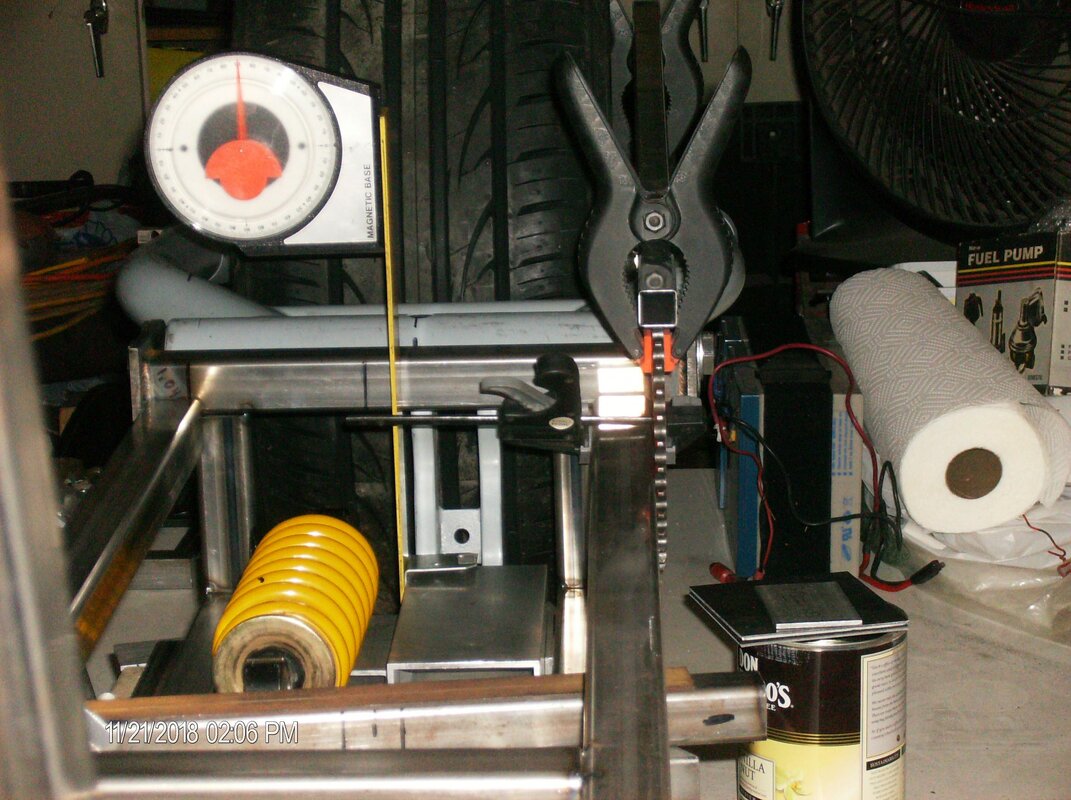

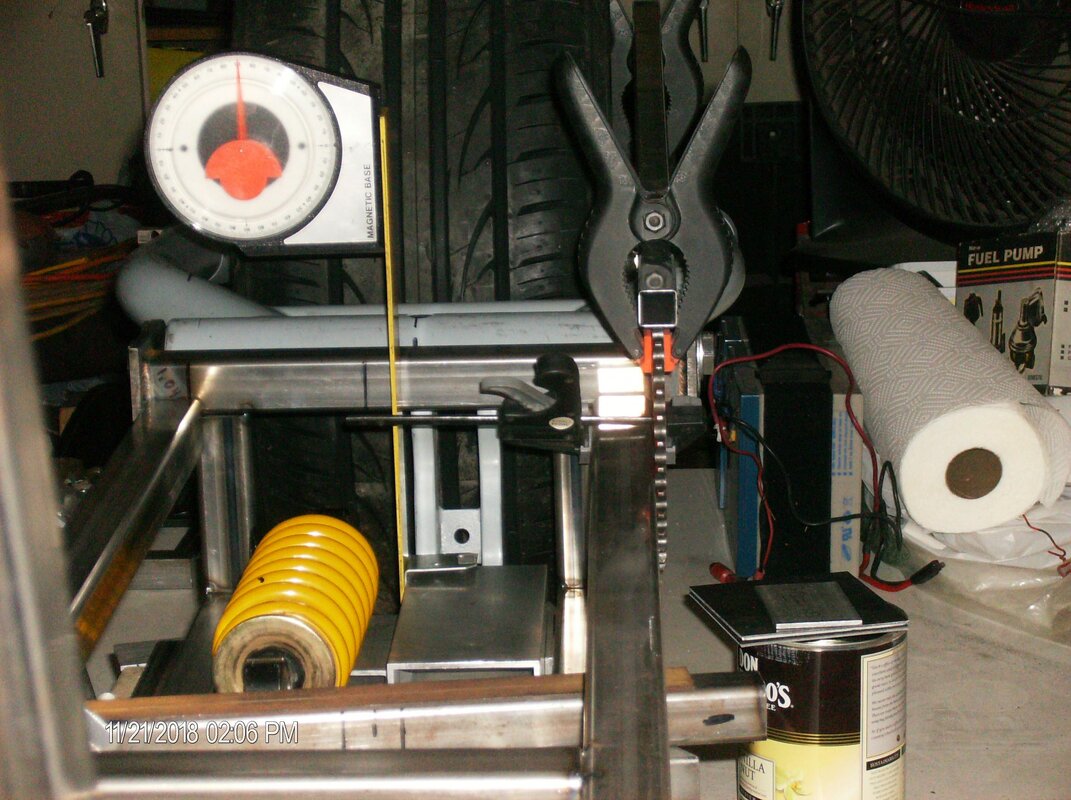

Time to do some mock up on the jack shaft diameter or how many teeth per diameter? Or remember that big pot hole that almost bottomed out the car, I think a 4" would ease my mind now to figure the teeth for a 530 chain (Harley) 2.75 dia. sprocket = 16T, so I am GUESSING about 25T and I'll try to use the same size engine sprocket. I have a 37T and it is 6". Wheel sprocket will be Harley 46T.

Now the up and down travel is less at the swing arm mounting as the rear is greater...Edit, There is a site for sprocket diameter to the number of teeth, 530 chain, 20T = 4" and 15T = 3" this will really help out for my jack shaft...

Now the up and down travel is less at the swing arm mounting as the rear is greater...Edit, There is a site for sprocket diameter to the number of teeth, 530 chain, 20T = 4" and 15T = 3" this will really help out for my jack shaft...

Now the up and down travel is less at the swing arm mounting as the rear is greater...Edit, There is a site for sprocket diameter to the number of teeth, 530 chain, 20T = 4" and 15T = 3" this will really help out for my jack shaft...

Now the up and down travel is less at the swing arm mounting as the rear is greater...Edit, There is a site for sprocket diameter to the number of teeth, 530 chain, 20T = 4" and 15T = 3" this will really help out for my jack shaft...

Last edited:

- Thread starter

- #78

RebelRouser

Yeaaa! eBay's snail mail is here, one day late, Harley sprocket 46T and flat head bolts for recessing to get a little closer to the swing arm side.

Yeaaa! eBay's snail mail is here, one day late, Harley sprocket 46T and flat head bolts for recessing to get a little closer to the swing arm side.

Dropped off at the machine shop for countersinking, This is why I bought a painted sprocket, did not want to cut up the chrome, so I'll just paint it the trike color RED, should be finished tomorrow then set up the wheel to swing arm and then back to the upper frame rails...

Yeaaa! eBay's snail mail is here, one day late, Harley sprocket 46T and flat head bolts for recessing to get a little closer to the swing arm side.

Yeaaa! eBay's snail mail is here, one day late, Harley sprocket 46T and flat head bolts for recessing to get a little closer to the swing arm side. Dropped off at the machine shop for countersinking, This is why I bought a painted sprocket, did not want to cut up the chrome, so I'll just paint it the trike color RED, should be finished tomorrow then set up the wheel to swing arm and then back to the upper frame rails...

LarryA

500+ Posts

can't keep my eyes off that rear wheel!!! All, is looking good!

- Thread starter

- #80

RebelRouser

Yesss, I like it more and more, wait till I ask my wife if she wants to learn how to polish it? She'll be laughing at me for a week...can't keep my eyes off that rear wheel!!! All, is looking good!

- Thread starter

- #81

RebelRouser

Back from the machine shop with the countersinking finished and trial fit,

Back from the machine shop with the countersinking finished and trial fit,

Now I have 3/8 (.375) side clearance form sprocket to swing arm plus 1/2 the sprocket is .150 so this gives me .525 for 1/2 the chain, which is about 1.000 wide total,:clapping: Measured the length for the axel spacers on each side, now to re-do the mounting bracket since the upper frame rail is going to be wider so that's next with the upper rails themselves widened, then to the jack shaft, more measurements tomorrow (Sunday) then off to my steel supplier for swing arm brackets 3/8 this time? and some tubing for the swing arm push rod and to figure the bell crank, :xzqxz:

Now I have 3/8 (.375) side clearance form sprocket to swing arm plus 1/2 the sprocket is .150 so this gives me .525 for 1/2 the chain, which is about 1.000 wide total,:clapping: Measured the length for the axel spacers on each side, now to re-do the mounting bracket since the upper frame rail is going to be wider so that's next with the upper rails themselves widened, then to the jack shaft, more measurements tomorrow (Sunday) then off to my steel supplier for swing arm brackets 3/8 this time? and some tubing for the swing arm push rod and to figure the bell crank, :xzqxz:

Back from the machine shop with the countersinking finished and trial fit,

Back from the machine shop with the countersinking finished and trial fit,

Now I have 3/8 (.375) side clearance form sprocket to swing arm plus 1/2 the sprocket is .150 so this gives me .525 for 1/2 the chain, which is about 1.000 wide total,:clapping: Measured the length for the axel spacers on each side, now to re-do the mounting bracket since the upper frame rail is going to be wider so that's next with the upper rails themselves widened, then to the jack shaft, more measurements tomorrow (Sunday) then off to my steel supplier for swing arm brackets 3/8 this time? and some tubing for the swing arm push rod and to figure the bell crank, :xzqxz:

Now I have 3/8 (.375) side clearance form sprocket to swing arm plus 1/2 the sprocket is .150 so this gives me .525 for 1/2 the chain, which is about 1.000 wide total,:clapping: Measured the length for the axel spacers on each side, now to re-do the mounting bracket since the upper frame rail is going to be wider so that's next with the upper rails themselves widened, then to the jack shaft, more measurements tomorrow (Sunday) then off to my steel supplier for swing arm brackets 3/8 this time? and some tubing for the swing arm push rod and to figure the bell crank, :xzqxz:I am just following this thread because it is interesting and I am learning new things and watching someone create what is in their mind. It is awesome.... I am not as knowledgeable as others here, but I do like to expand my mind and that is done daily here.Merry Xmas to All, and please enjoy your family and friends, oh and keep safe everyone.

- Thread starter

- #84

- Thread starter

- #85

Damn I hate doing things wrong, That's what I get for NOT being an engineer, (re-work)View attachment 65215This should work?

yup that is the right direction one problem i might see is the swing arm where the wheel is attached much longer than the arm where the shock is mounted you need a short through super strong spring...but being light you might be okay the other potential issue the short travel on the connecting rod is so short it will may change the realized spring rate hope that makes sense it would help if you rotate the arm clockwise by moving the pivot to the front an lengthening the tie rod