Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebel RT

- Thread starter TomyJ

- Start date

LarryA

500+ Posts

welcome to trike talk!........looks like an interesting project. Is the concept trike an actual production trike or is it a "one of" that you are going to reproduce? Also what about the frame that is pictured? used to mock up powertrain and body panels? Please explain about frame you are drawing. similar to one you have? definitley looking forward to this build!

- Thread starter

- #3

Rebel Trike

Hi Larry, I found the drawing on the Internet, I like the way it sits (attitude), I was ready to junk a Chinese Quad frame and the two started looking alike except I do like the idea of killing myself with a cheap welds and wall thickness, but yet I want about a 250cc engine, so I will mate the two in a drawing and make the new frame 1.25x.125 wall. Body panels??? Parts bike is from a 250cc Rebel.

welcome to trike talk!........looks like an interesting project. Is the concept trike an actual production trike or is it a "one of" that you are going to reproduce? Also what about the frame that is pictured? used to mock up powertrain and body panels? Please explain about frame you are drawing. similar to one you have? definitley looking forward to this build!

Hi Larry, I found the drawing on the Internet, I like the way it sits (attitude), I was ready to junk a Chinese Quad frame and the two started looking alike except I do like the idea of killing myself with a cheap welds and wall thickness, but yet I want about a 250cc engine, so I will mate the two in a drawing and make the new frame 1.25x.125 wall. Body panels??? Parts bike is from a 250cc Rebel.

LarryA

500+ Posts

the concept trike is a good looking machine.....a worthy project... yes agree, trust your own frame and welding. That machine looks too fast to trust a frame/ welding that is questionable.

- Thread starter

- #7

RebelRouser

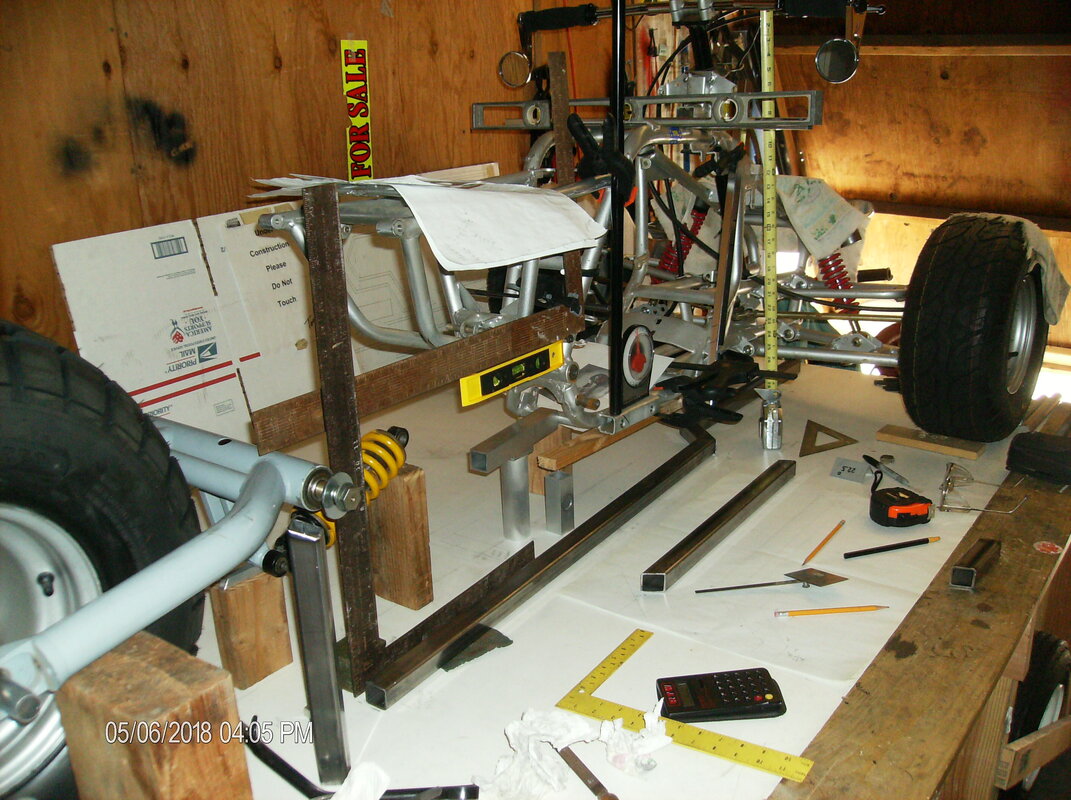

HF Chop saw, this 1.25x.120 wall sq. tubing, the cuts are bad for this 2HP motor, I have to use the HF 12" sander 36 grit to get the length to size and the angles correct. Lower frame rails are to size, now will start the lower a-arm mounting brackets, then go to the middle tie with steering and swing arm braces.

HF Chop saw, this 1.25x.120 wall sq. tubing, the cuts are bad for this 2HP motor, I have to use the HF 12" sander 36 grit to get the length to size and the angles correct. Lower frame rails are to size, now will start the lower a-arm mounting brackets, then go to the middle tie with steering and swing arm braces.

HF Chop saw, this 1.25x.120 wall sq. tubing, the cuts are bad for this 2HP motor, I have to use the HF 12" sander 36 grit to get the length to size and the angles correct. Lower frame rails are to size, now will start the lower a-arm mounting brackets, then go to the middle tie with steering and swing arm braces.

HF Chop saw, this 1.25x.120 wall sq. tubing, the cuts are bad for this 2HP motor, I have to use the HF 12" sander 36 grit to get the length to size and the angles correct. Lower frame rails are to size, now will start the lower a-arm mounting brackets, then go to the middle tie with steering and swing arm braces.The front coil over location can use a little more wow! What do you all think? Next I will be setting up the brackets for the control arms, 3/16 x 1 1/4 with 1/8 gussets top and bottom.View attachment 57395View attachment 57396

just curious.... are you planning on some sort of bell crank for the shocks or using the stock location?

- Thread starter

- #10

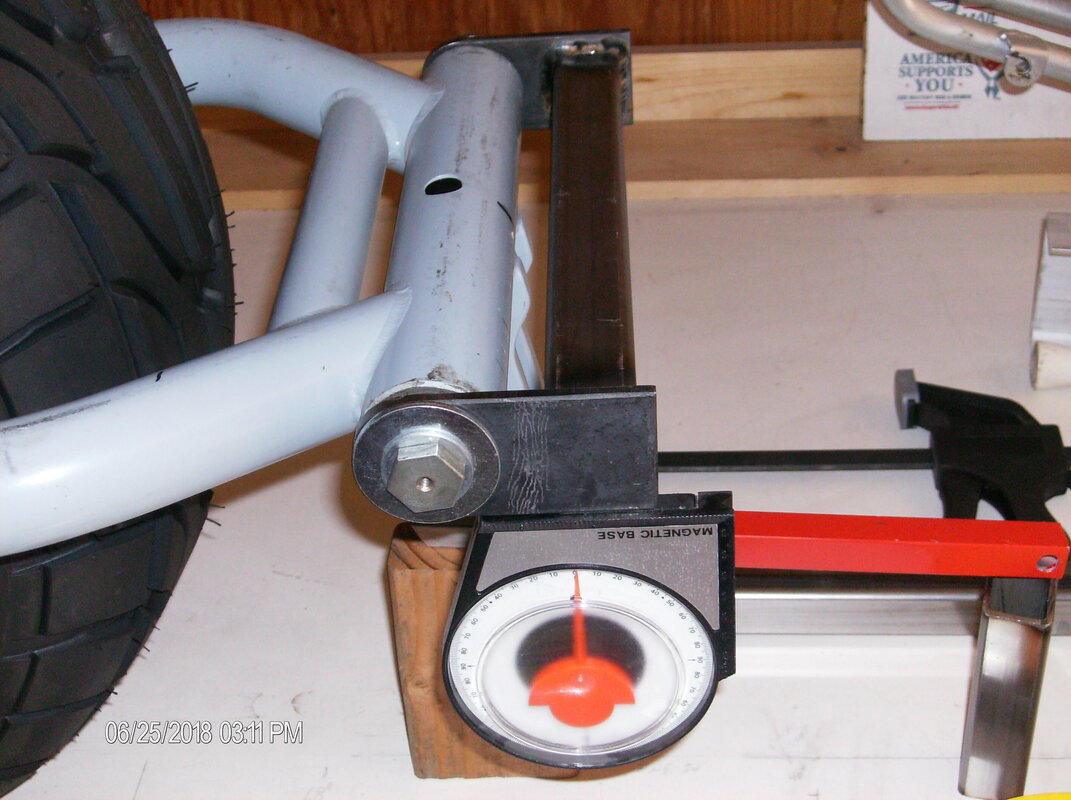

View attachment 57431View attachment 57432Sorta... Stock is to easy, and pushrods have more adjustment.

like the way u think.... stock is easy!!! thought it might be the case

- Thread starter

- #12

- Thread starter

- #15

- Thread starter

- #18

RebelRouser

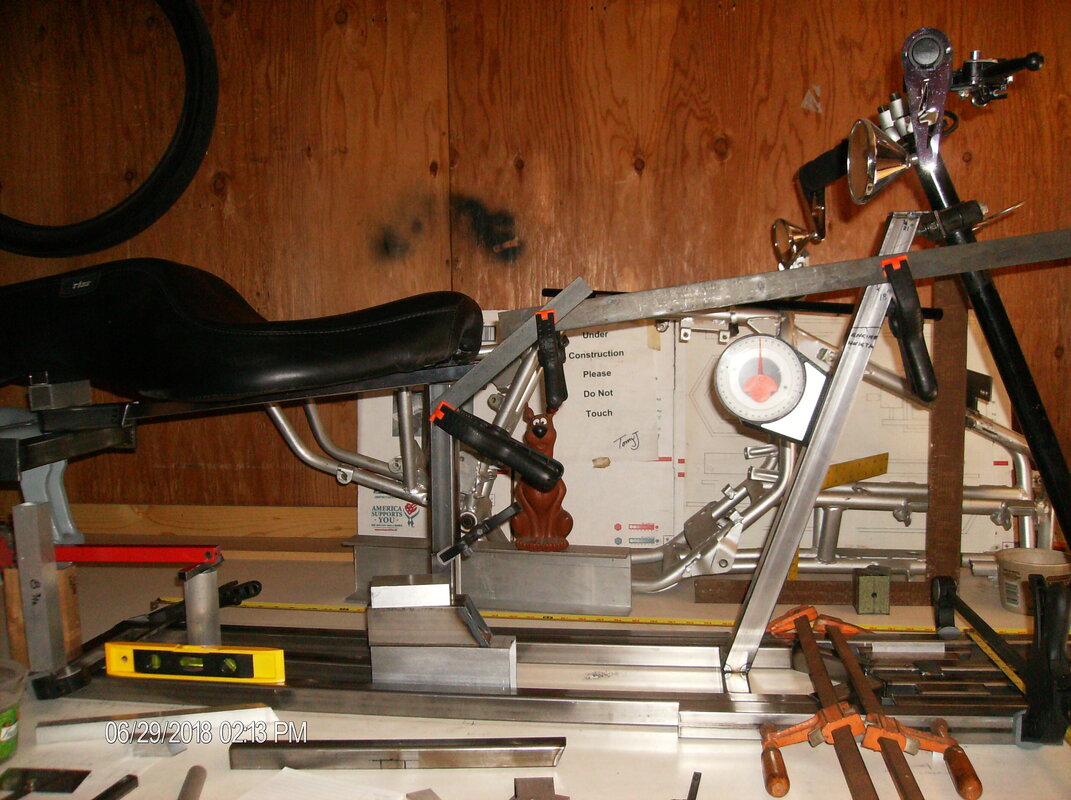

Which one? the trike?, I like the look, big tires no so, they are golf cart DOT, remember this is only 250cc, total length will be 7ft, width 4ft overall, I like these builds to fit under my work bench while I'm working on the next one. Have fun and ride safe...

Which one? the trike?, I like the look, big tires no so, they are golf cart DOT, remember this is only 250cc, total length will be 7ft, width 4ft overall, I like these builds to fit under my work bench while I'm working on the next one. Have fun and ride safe...

- Thread starter

- #20

RebelRouser

Welding on the lower control arms done, brackets did not warp from heat, on the other hand the swing arm bracket did, both sides pulled in about 1/8, need to open it back to final measurement. Next will be the lower steering mounts, then the upper steering mounts.

Read more: http://reversetrike.proboards.com/thread/895/concept-407?page=2#ixzz5JOooGjYr

Welding on the lower control arms done, brackets did not warp from heat, on the other hand the swing arm bracket did, both sides pulled in about 1/8, need to open it back to final measurement. Next will be the lower steering mounts, then the upper steering mounts.

Read more: http://reversetrike.proboards.com/thread/895/concept-407?page=2#ixzz5JOooGjYr

LarryA

500+ Posts

large welds on one side, means major warp, either minimize welds or use a strong back to pull or push out warp and or twist....sometimes a little force applied and some heat on the offending weld will take out the warp. At work, Bobcat company.....lots of time spent on robot welding sequence,part preload and other considerations.....still heavy mtl. heavy welds, definite problems to solve. On welding fixtures....many times the fixture frame was welded up then sent out to be "normalized" in a large oven....then finally machined. on one off projects like our trikes, become a study in straightening techniques! good luck...looking good!

- Thread starter

- #23

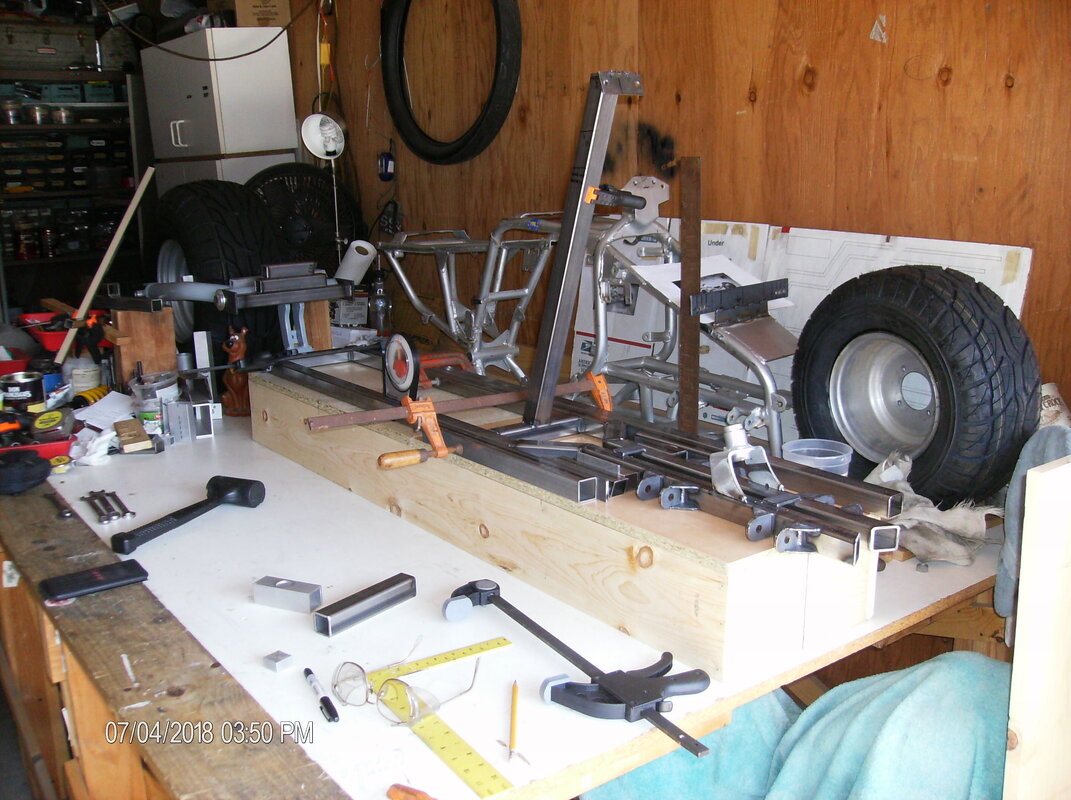

RebelRouser

Thank you Larry these one offs can be a bitch, I should have put that straighten bar in right after tacking, live and learn, but then again I am not a welder... I am still fighting with STRAIGHTNESS, need to be looking at a few more shops that can handle it. My next RT will be really on straightness, I am looking for a table 12" wide by 5ft long, the next RT will require a table 24" wide and 7ft long, so I'm looking at both.large welds on one side, means major warp, either minimize welds or use a strong back to pull or push out warp and or twist....sometimes a little force applied and some heat on the offending weld will take out the warp. At work, Bobcat company.....lots of time spent on robot welding sequence,part preload and other considerations.....still heavy mtl. heavy welds, definite problems to solve. On welding fixtures....many times the fixture frame was welded up then sent out to be "normalized" in a large oven....then finally machined. on one off projects like our trikes, become a study in straightening techniques! good luck...looking good!

is that your gargoyle sitting there keeping an eye on you??