- Thread starter

- #61

Good solid plan, I am following. Best of luck:clapping:

Thanks Jack!! ThumbUp

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Good solid plan, I am following. Best of luck:clapping:

Good solid plan, I am following. Best of luck:clapping:

I have another question..... Upon removing my axles, I first checked to see what the torque was on bolts. They were all around 60 ft. lbs. which seems pretty low to me.... What would you suggest to torque them at? Still waiting for a call from the welder.... Thanks. Ray

45-50 ft lbs using a cross pattern

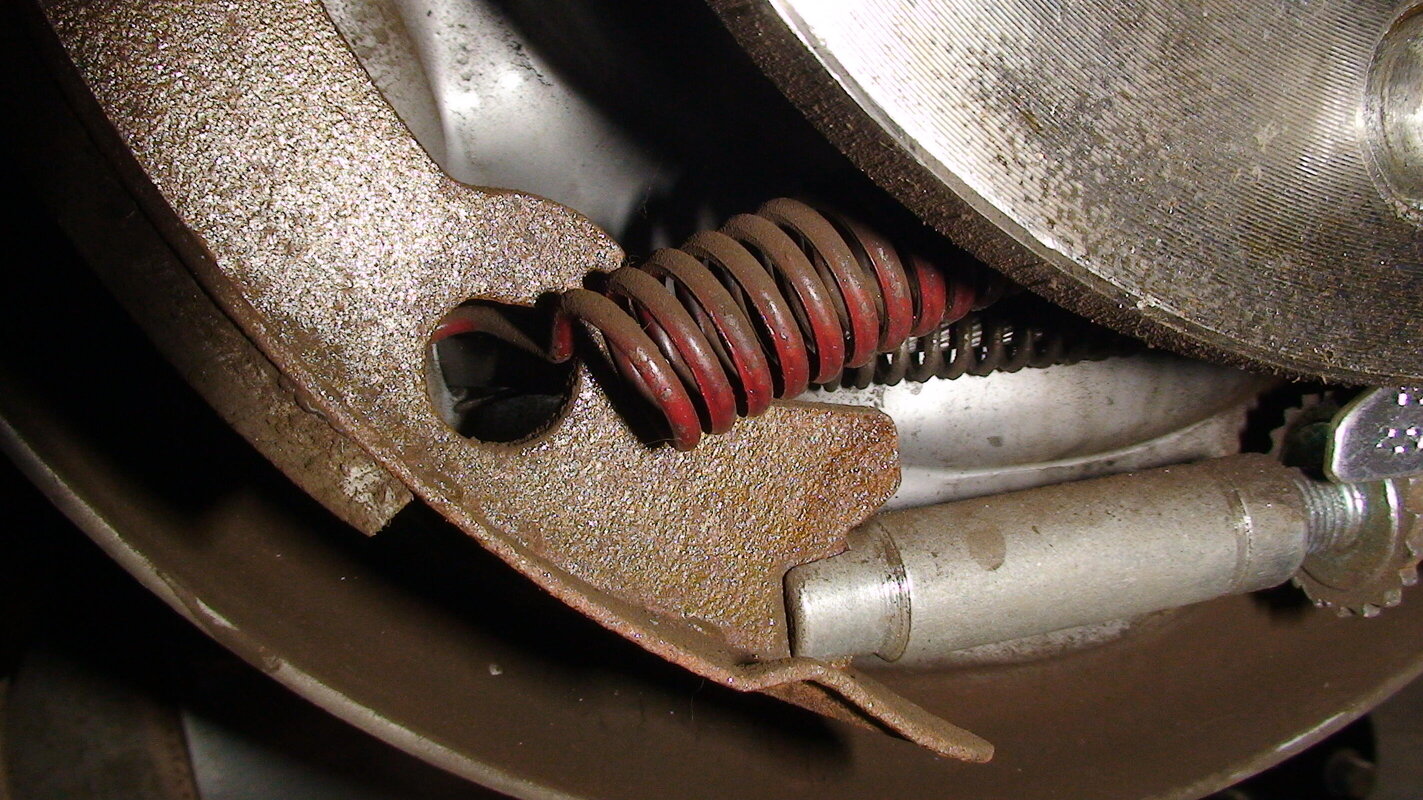

I think I mentioned before ... Axle lube contaminating shoes or inner drum surfaces will cause grabbing if it leaks into the drum area. One might think it'd be slicker, but it's not.

About the torque on nuts securing backing plates to the axle ... I'd think 40-50 ft lbs would be a plenty. The bolts aren't wheel bolts.

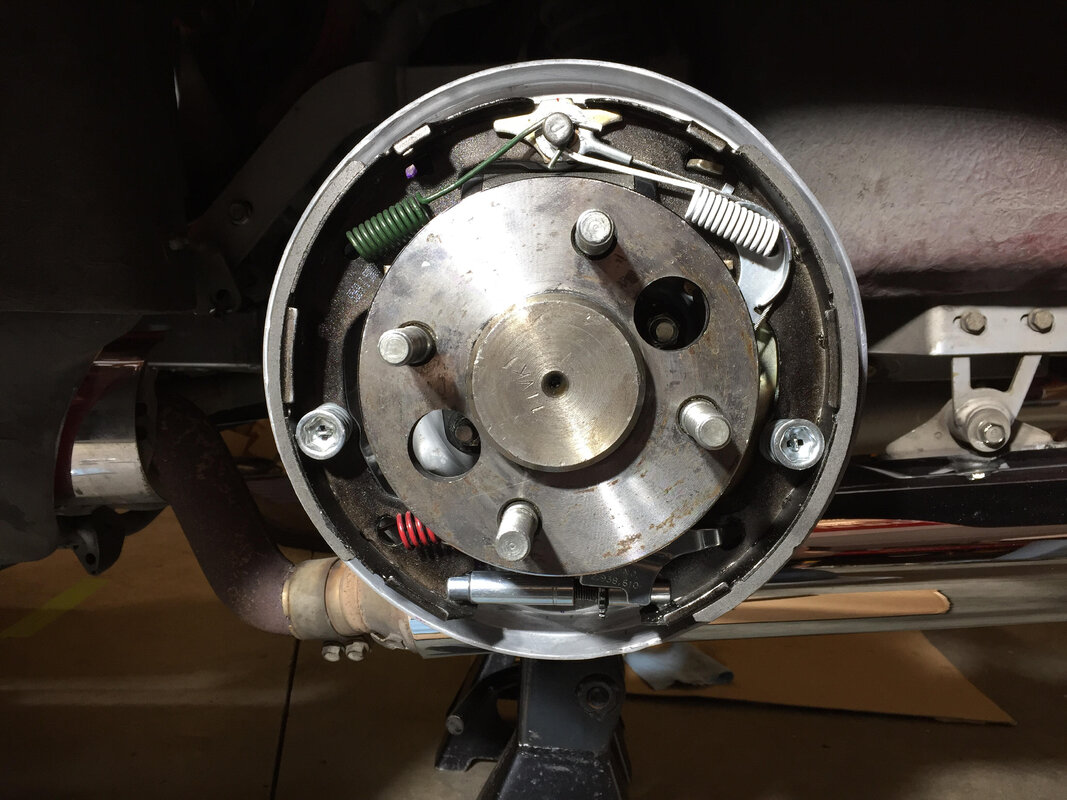

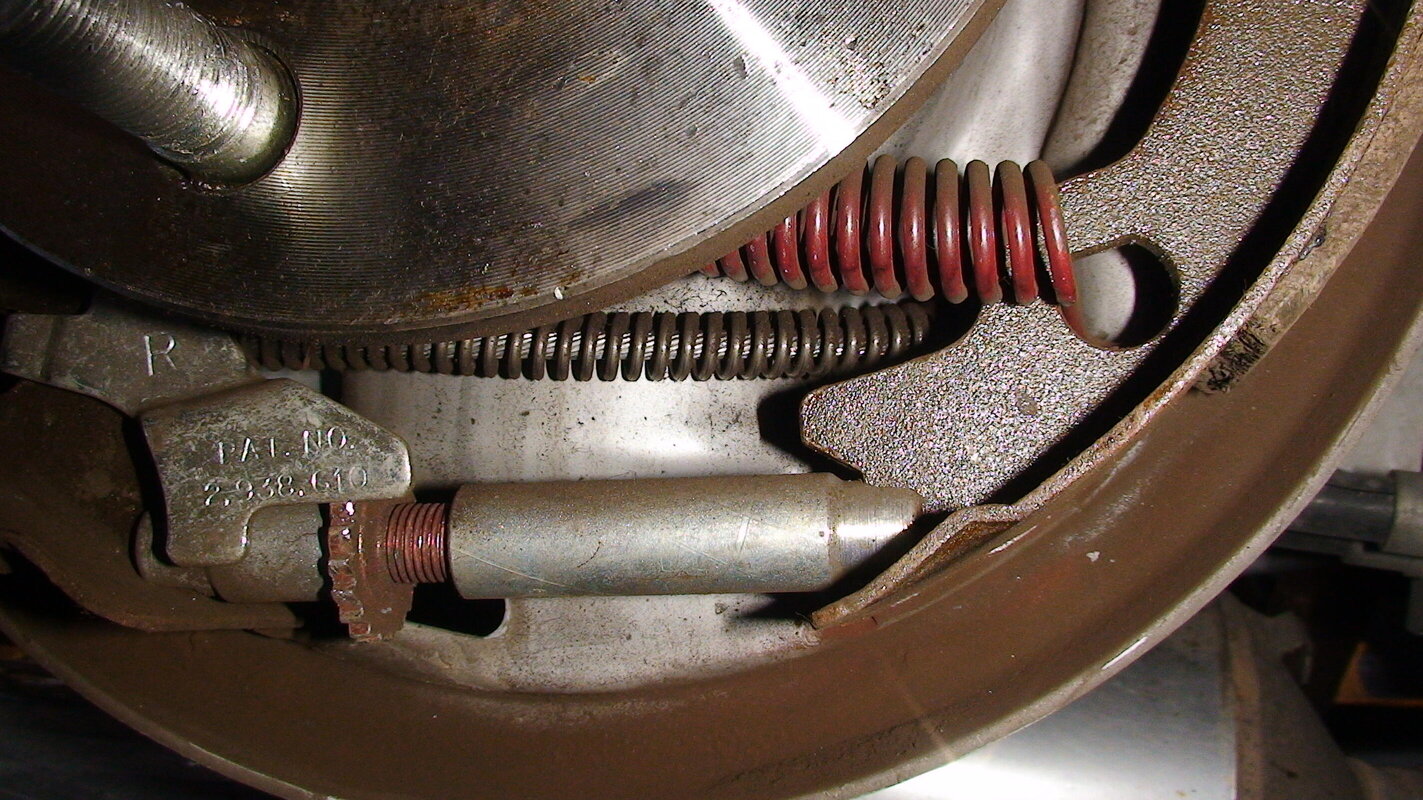

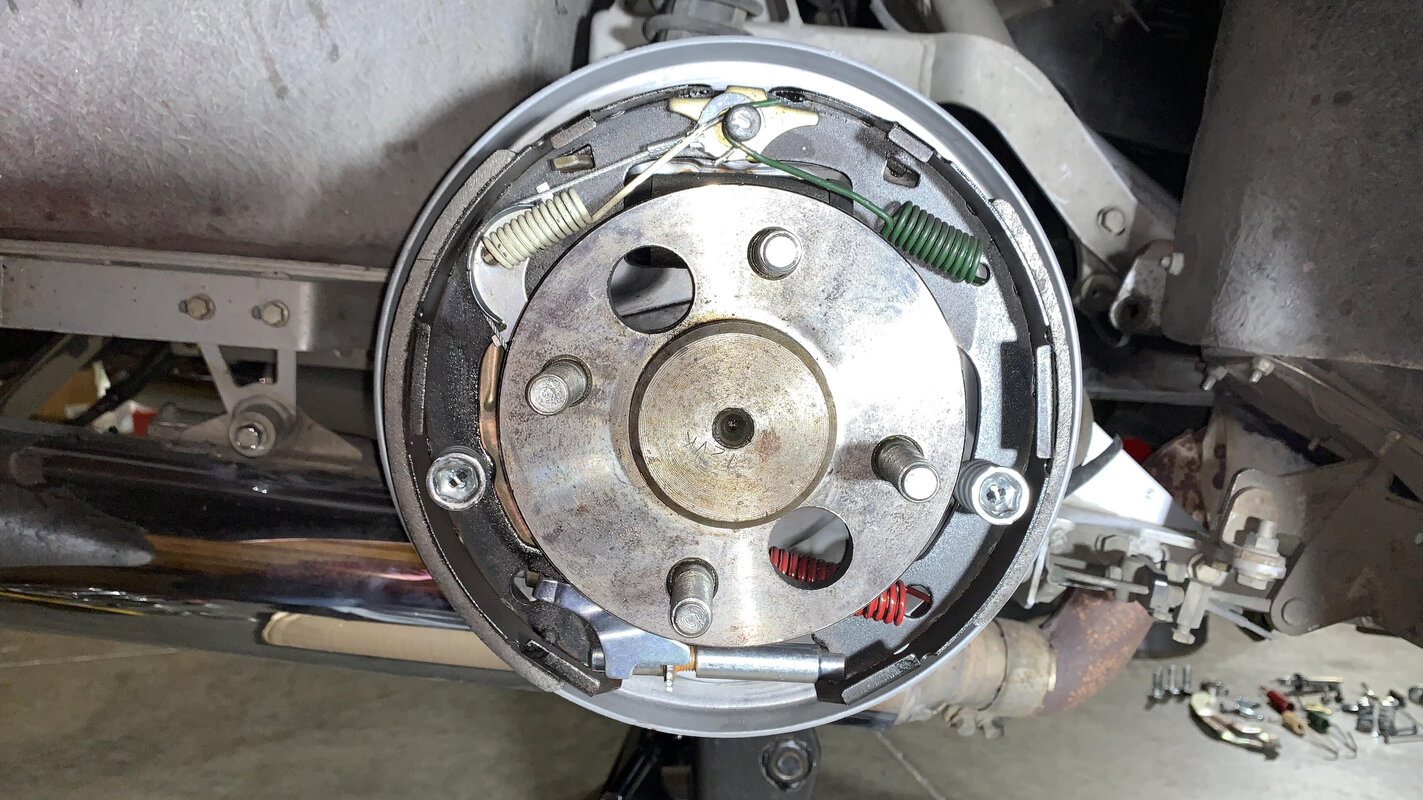

Brakes are done!! Had to be the backer plates.... one or both of two things caused the issue with locking up. Either the gouged surface of the nubs or the plates being slightly bent, I would say both. The wierd thing is, I didn't have any problems with the brakes until I decided to replace them while replacing the tires. I took a successful 20 mile test run and readjusted and took another one. All braking was in a nice straight line as it should be. I'll be taking about a 300 mile run in about a week and will check once again. Didn't have to readjust the parking brake at all. I have about an 1/8" play between the leading shoe and the PB bracket at the anti-rattle spring. I torqued the axle bolts at 50 ft lbs as you guys suggested using a cross pattern.

In regards to the new wheel cylinders, that was easy-peasy bleeding due to the speed bleeders I installed. I replaced all of my bleeders including the one for the clutch. Well worth every penny! Nice to have my bike back on the road!! I want to thank you guys for hanging in their with me helping me along!! It meant more than I can say knowing I could turn here for your help! I sincerely appreciate it! Thank You, Big Time!! :yahoo:ThumbUp

View attachment 114062

View attachment 114059

View attachment 114060

View attachment 114061

Good on you, I like a happy ending:clapping:

Just for fun before you start looking at other parts recheck the adjustment.If its loose again its possible you may have that adjuster in backwards.If so you wouldn't be the first to do it.

New Right

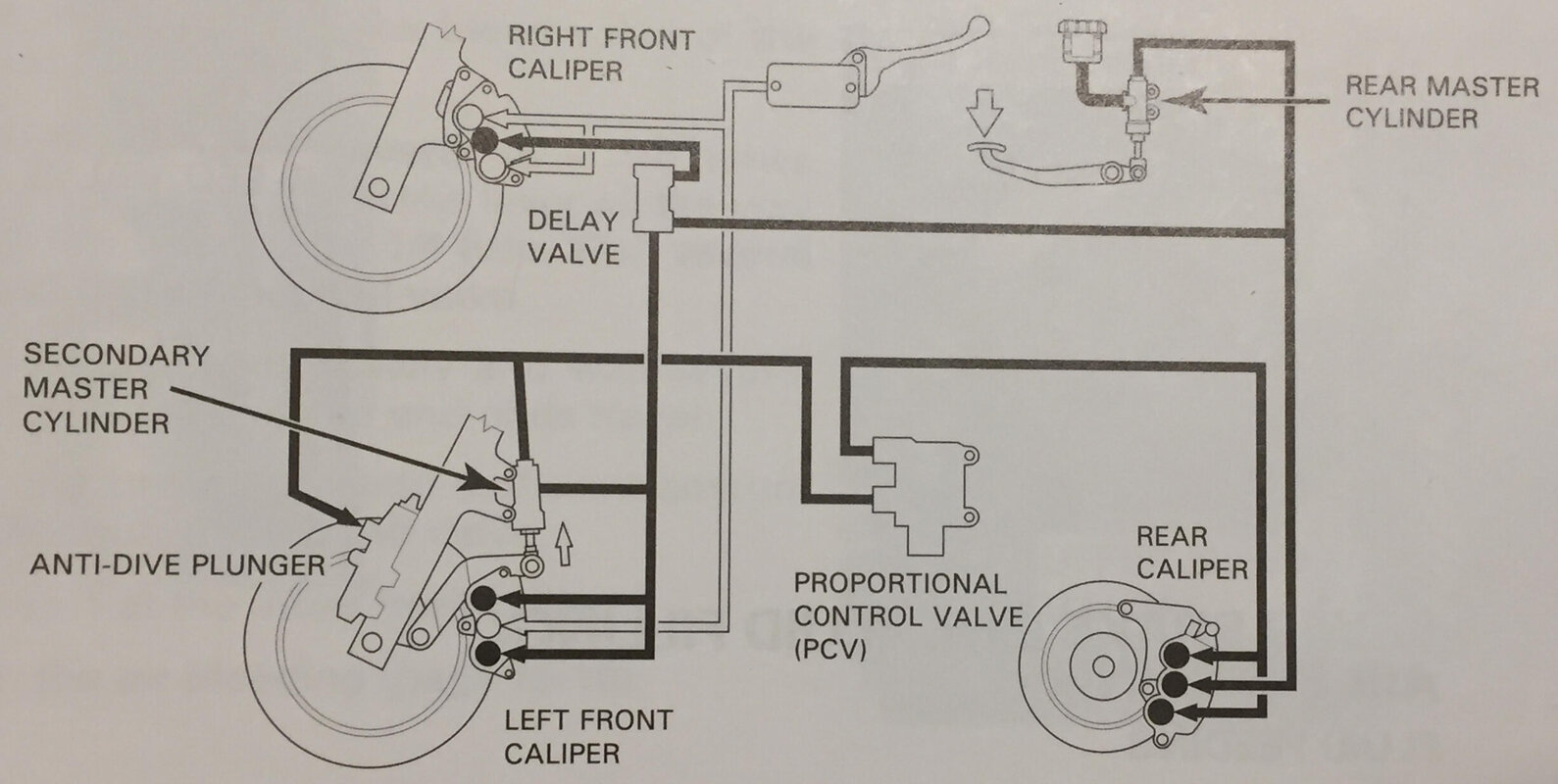

New RightRay, I don't think the rear master is the problem, both rears would probably lock up, from the diagram it appears maybe your brakes are a linked design? i dunno much about the hydraulic set up your trike uses, I dunno if you could re plumb the rear brakes to isolate them totally from the front and the anti dive

I dunno if this will work on a Honda trike kit, Take every brake line and component off the bike except for the calipers and master cylinders.

Connect a brake line from the rear master to the rear wheel cylinders ( you could run 1 line with a t union so you could split the line , 1 to each wheel cylinder

Connect a brake line from the front master to the right front caliper, and send a jumper over to the left front caliper.

This would eliminate the linking and ant dive, I dunno how effective it would be, or how good the braking would be, the rear brakes could benefit from an adjustable residual check valve also

In theory this would give you 2 separate independent braking systems

So looking at the first post it seems this started when you changed the shoes. So going back to where this started I think I'd try a different brand of brake shoes. Just because why not you've changed everything else.

Thanks for pointing that out..... I thought I mentioned it but, I see that I didn't. I did install another new set of shoes made by Duralast (Auto Zone) The first new set was NAPA. I thought about replacing the new NAPA wheel cylinders as well but, instead of spendng another $30.00 a piece I took them apart for inspection. Both, left and right WC's looked great. ThumbUp

If you decide to change the rear shoes( I would surely try this) get riveted shoes

WE had bad luck with most bonded shoes

Not much I can think of at this point. U could check 2 make sure both wheel cylinders are the same bore diameter. Wheel cylinders can be physically the same size with different bores. Common on old VW,s I once had a car come in,customer did own brakes and one side wouldn't work. He had jammed a piece of wood in the brake line to keep it from leaking. He forgot about it and put it together. The thing that bothers me about this is I didn't see where you had this problem before you put the brakes on. That says it's something you inadvertently created.:Shrug:

Not knowing your ability to repair things I just throw this out there. I'm not trying to aggravate you. But we're looking at a needle in a haystack at this point. So not being there I try to think of things that could create a problem like this.:Shrug:

Thanks.... I didn't have any problems before I replaced everything. The sole reason I did so was because I was replacing my rear tires and thought I would simply change the shoes out..... I guess I thought wrong. I replaced everything I did here back in 2015 and never had an issue. I totally went through installation / removal three times on this job. Everything is installed as it should be. It's been double checked each and every time. Such a simple job that's been nothing but a major P.I.A. I even installed speed bleeders to make sure I wouldn't introduce air into the system. In regards to the new wheel cylinders, they appeared to be fine and never thought about measuring them.... Thanks again, appreciate your thoughts and help. Ray ThumbUp

Not knowing your ability to repair things I just throw this out there. I'm not trying to aggravate you. But we're looking at a needle in a haystack at this point. So not being there I try to think of things that could create a problem like this.:Shrug:

Very good point

- - - Updated - - -

The rubber seals inside the cylinders are usually marked what diameter they are, most of the 9 inch Bendix type brakes used either 3/4 or 7/8 size

Thanks Jack.... ThumbUp