- Thread starter

- #31

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Brake Shoes Locking Up 2004 Lehman Goldwing

- Thread starter Ray & Paula

- Start date

- Thread starter

- #32

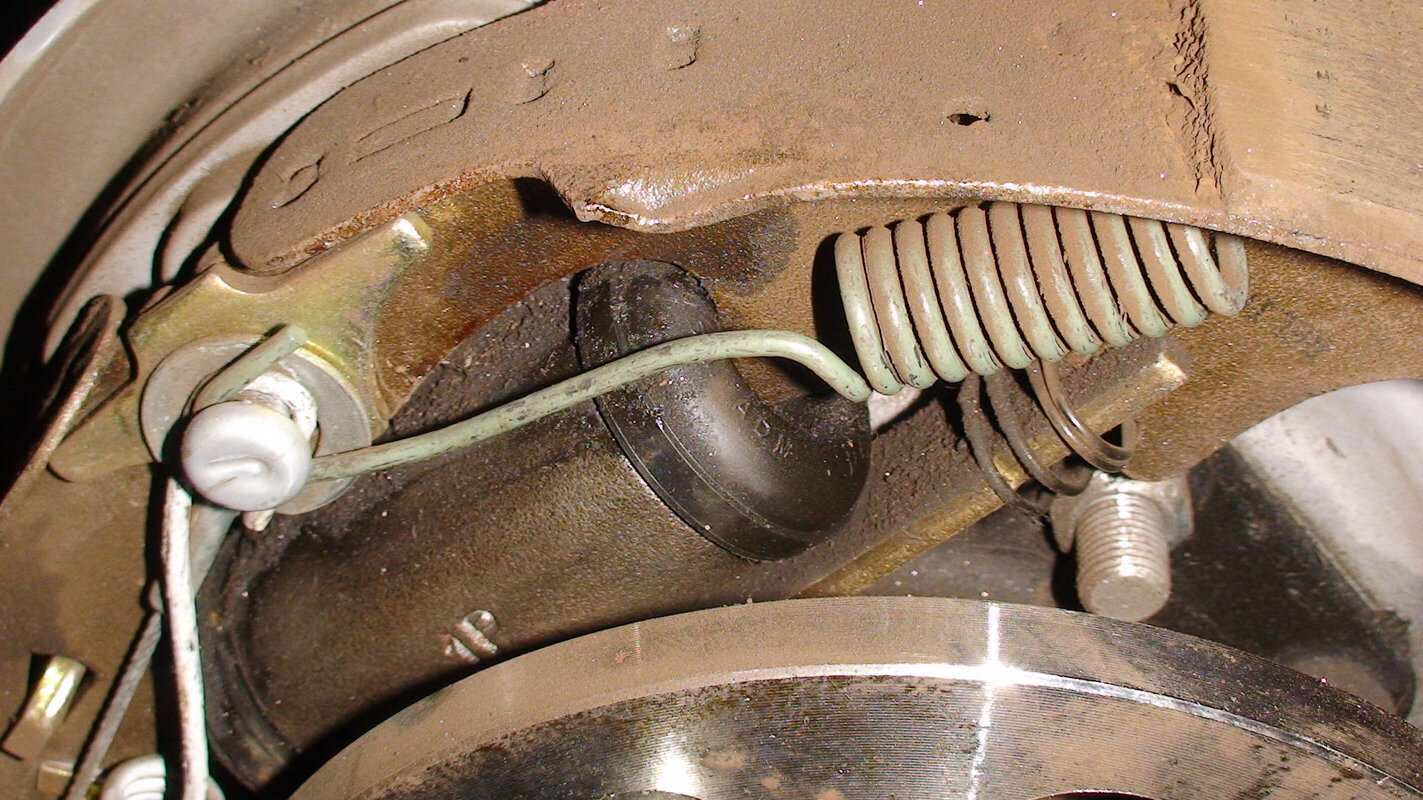

I got to thinking that the backing plate is bolted with the nuts being on the inner side. I came across the following pic from when I removed my original brakes & wheel cylinder that has the bolts showing. Wouldn't I just need to remove the four nuts that holds it? Thanks again.... Ray

View attachment 113710

Also, in the pic on the right side is my parking brake cables to the bracket on the handle.

- Thread starter

- #33

I now see why the axle has to be removed... The wheel. Dah...

If it bent that easy,I would just bend it back. You have the axle flange to work off of. A straight edge across the flange and a ruler and you should have no problem.:Shrug:

- Thread starter

- #35

If it bent that easy,I would just bend it back. You have the axle flange to work off of. A straight edge across the flange and a ruler and you should have no problem.:Shrug:

Thanks for the help. I'll take a look at to see if I can. If I can get a straight edge on it to check all around, I'll give it a shot. At this point, I have nothing to lose. Thanks again. Ray

- Thread starter

- #36

I did one more road test after adjusting the shoes on both Lt & Rt sides to where they just started to drag. I was able to go a little further testing the brakes but, it went back to grabbing once again on the left. Got home, jacked up the rear end and the left side had a lot of drag until it cooled off some. I then backed off the brake shoes for drum removal.

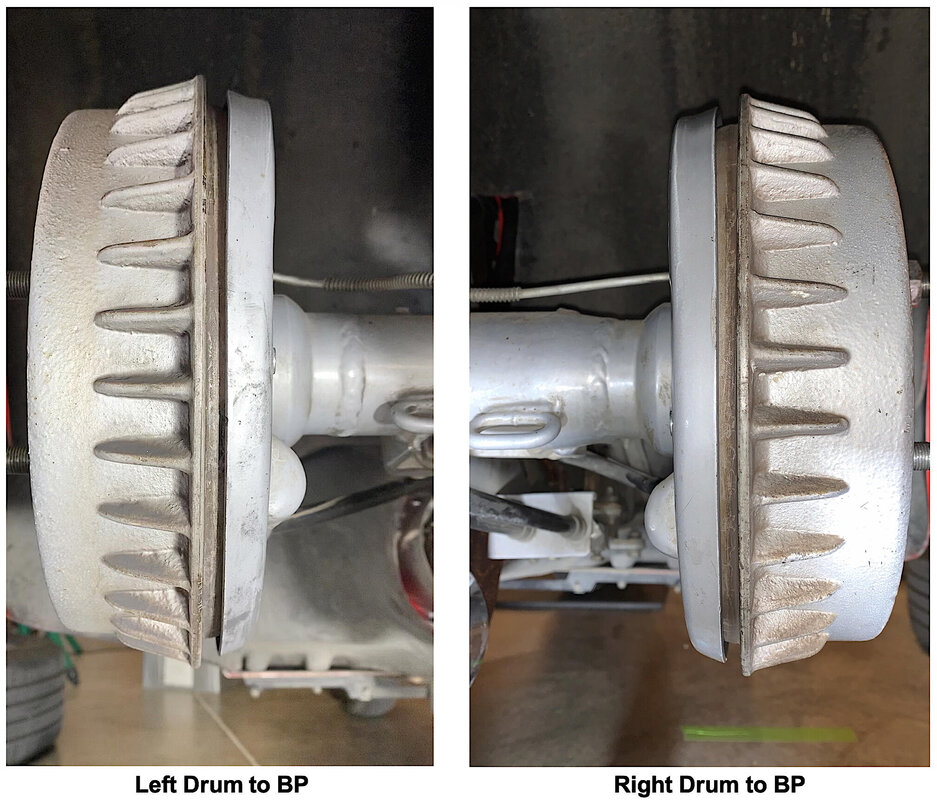

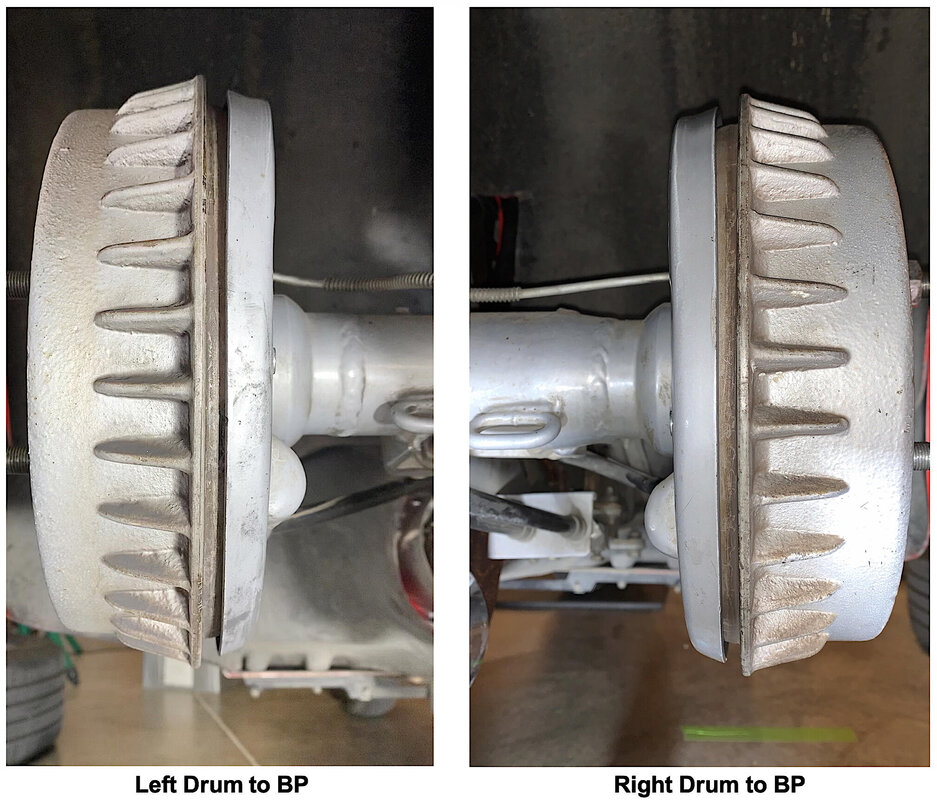

Wanting to check the distance from drum to backer plate again, I installed a couple lug nuts with washers as spacers. The drum was closer than my previous measurement and looks identical to the right side in both measurement and feel as shown in the pic's below. Keep in mind as I mentioned earlier on, I never had a problem backing off and removing the right side drum for shoe replacement in the past. Now, I believe that the backer plate on the left isn't bent.

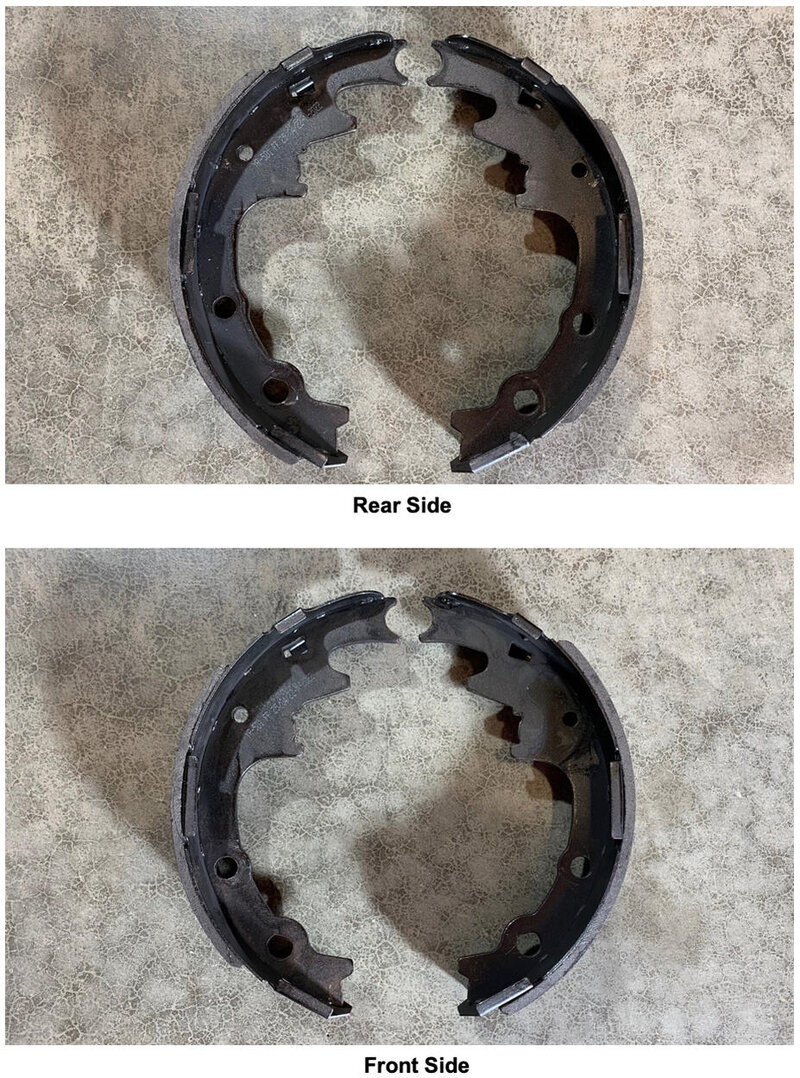

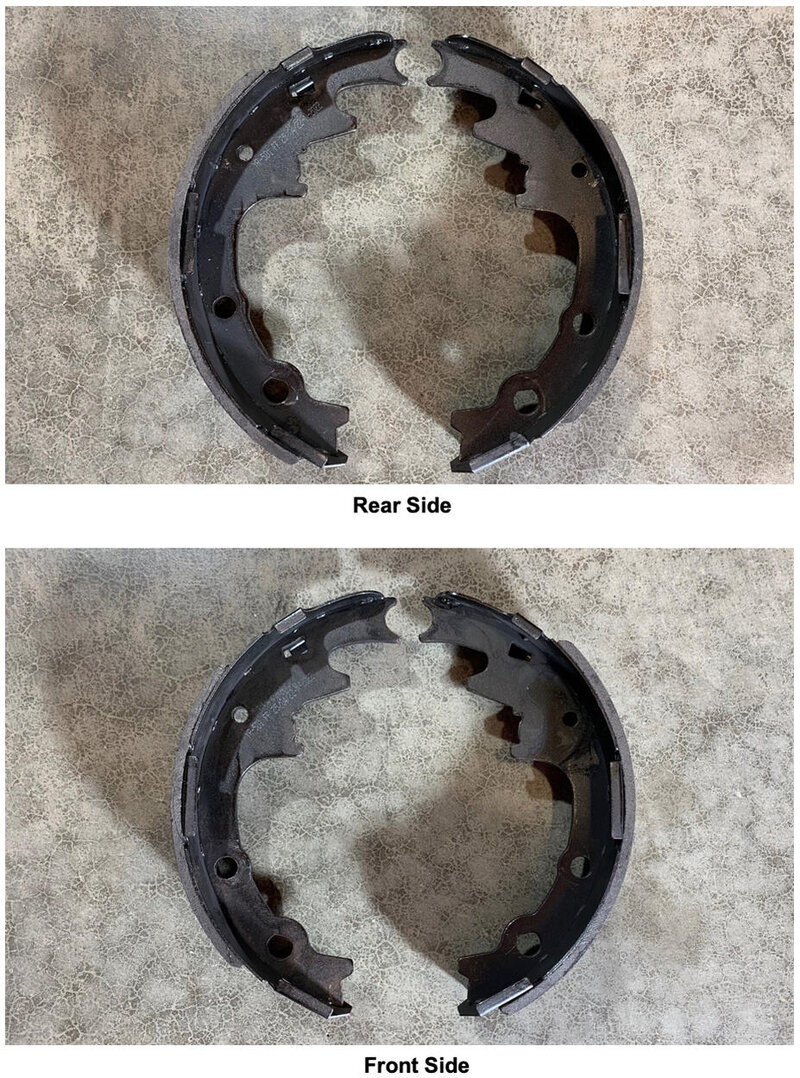

Problem now is the high spots that I greased are gouged on the left side as shown below. I'm not sure if sanding or grinding them back smooth is a good idea or not?? One would thing, did this guy install the proper shoes... I installed NAPA TS474 as I did last time in 2015. The shoes show some wear but, even across. Since these went through hell during these tests, I'm going to replace them once again but, not until I get to the bottom of this. Thanks. Ray

Wanting to check the distance from drum to backer plate again, I installed a couple lug nuts with washers as spacers. The drum was closer than my previous measurement and looks identical to the right side in both measurement and feel as shown in the pic's below. Keep in mind as I mentioned earlier on, I never had a problem backing off and removing the right side drum for shoe replacement in the past. Now, I believe that the backer plate on the left isn't bent.

Problem now is the high spots that I greased are gouged on the left side as shown below. I'm not sure if sanding or grinding them back smooth is a good idea or not?? One would thing, did this guy install the proper shoes... I installed NAPA TS474 as I did last time in 2015. The shoes show some wear but, even across. Since these went through hell during these tests, I'm going to replace them once again but, not until I get to the bottom of this. Thanks. Ray

Jack Klarich

Guest

Bendix type brakes always gouge the backing plates more it seems

Backing plates are stamped steel and pretty thin, go easy sanding the high spots

The plates still look bent at the top

Have the brakes always pulled and locked even before the overhaul?

Backing plates are stamped steel and pretty thin, go easy sanding the high spots

The plates still look bent at the top

Have the brakes always pulled and locked even before the overhaul?

Make sure the wheel cylinder isn't seized. Fords are famous for it.

- Thread starter

- #39

Bendix type brakes always gouge the backing plates more it seems

Backing plates are stamped steel and pretty thin, go easy sanding the high spots

The plates still look bent at the top

Have the brakes always pulled and locked even before the overhaul?

Thanks Jack.... I'll be careful if I sand the high spots. As for the backing plates, only reason I feel that it may not be the problem is due to never forcing the right side off, along with never having a problem. I also felt between the Lt & Rt sides comparing them which feels the same. The top is wider than the bottom on both. What's even more wierd, the right side in the comparison pic's looks wider on the top, but doesn't feel like it.

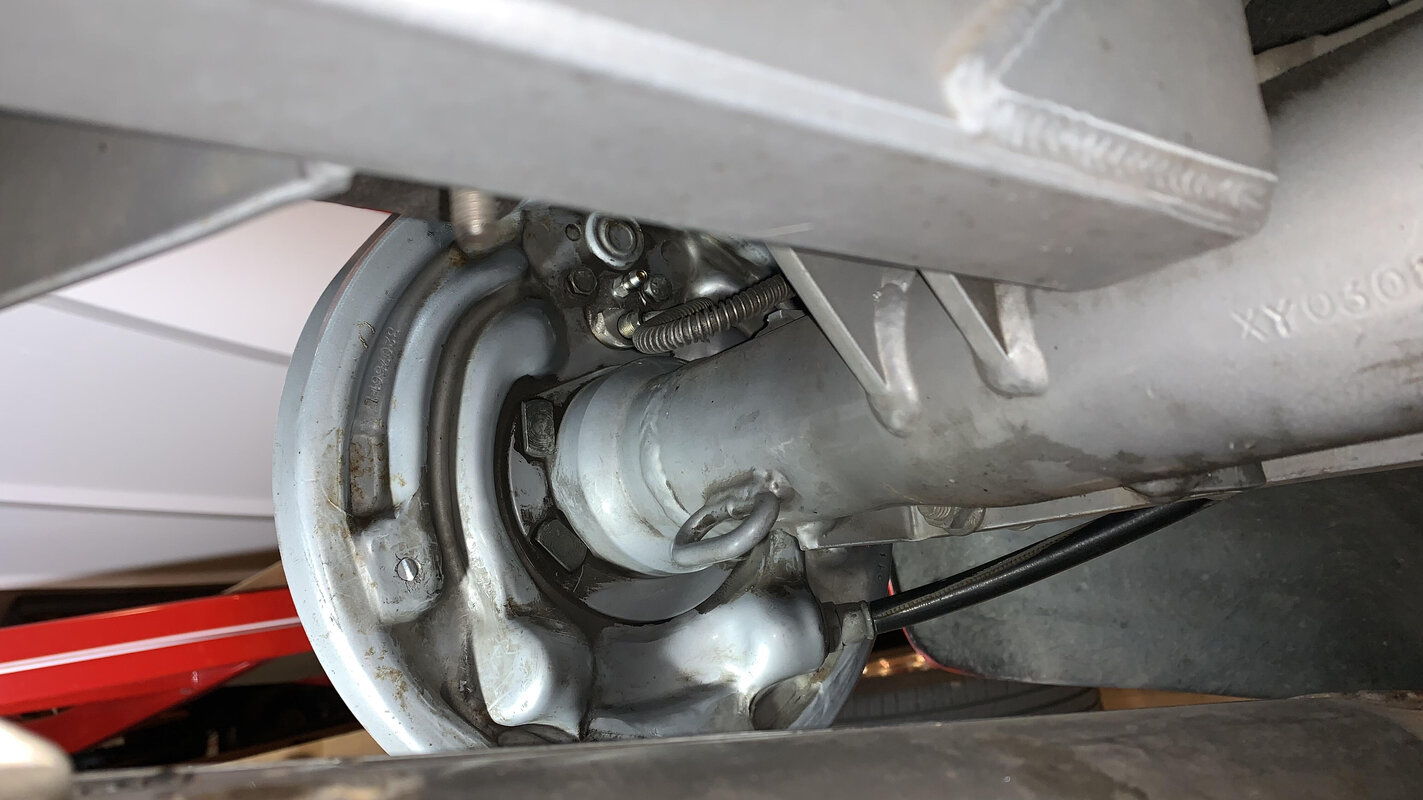

I removed the shoes and took some pic's of the backing plate which had a number stamped on it 3207561-L and 2119A. Other than that, there isn't anything else stamped on it. I've been searching all over starting with Bendix and couldn't find anything with those number's. I couldn't find a cross reference chart as well. I've been trying to find more information about pulling/removing the axle and came across some on YouTube but, not for the the Ford years from the list from NAPA so far. What I did see, seems to be a fairly straight forward job with some having a C-clip and some not.

One person stated to try to keep the gears in place due to difficulty placing them back. I may make a seperate post to see if anyone has one like mine that has removed the axle for one thing or another. The following is a few pic's of the back side of the backing plate with numbers along with the rear end. That bar leading to the rear end is part of my receiver/hitch which can be removed quite easily. Thanks again, appreciate it. Ray ThumbUp

- Thread starter

- #40

Make sure the wheel cylinder isn't seized. Fords are famous for it.

Thanks.... Just replaced both sides with the shoes but, that doesn't make them good. I'll have my wife press down on the foot pedal while I feel for action. Thank again. ThumbUp

Jack Klarich

Guest

The 4 nuts viewed thru the holes on the flange of the axle, remove them, you may need to put the drum on backwards with 2 nuts and use like a slide hammer to pop the axles out

No need to worry about gears falling out with this type of rear end ( only with C clip type rear

ends) you need to use caution

Now with axles out look in the axle tube at the grease seal, if it is overly wet and grease build up outside the seal replace seal, be sure to lube the lip of the seal

No need to worry about gears falling out with this type of rear end ( only with C clip type rear

ends) you need to use caution

Now with axles out look in the axle tube at the grease seal, if it is overly wet and grease build up outside the seal replace seal, be sure to lube the lip of the seal

- Thread starter

- #42

The 4 nuts viewed thru the holes on the flange of the axle, remove them, you may need to put the drum on backwards with 2 nuts and use like a slide hammer to pop the axles out

I may be able to borrow one from an auto parts store if needed. I would hate to have to buy one.

No need to worry about gears falling out with this type of rear end ( only with C clip type rear ends) you need to use caution

That's great news!

Now with axles out look in the axle tube at the grease seal, if it is overly wet and grease build up outside the seal replace seal, be sure to lube the lip of the seal

I will definitely do that.... Hopefully I'll come across removal on YouTube. Now to find the backer plates... Thanks again, you've been nothing short of Awesome!! Ray

- Thread starter

- #43

- Thread starter

- #44

Just came across the following video.... It would be nice if mine came out like this... See the first minute and a half.

Jack Klarich

Guest

Your axles should come out this way, tho the bearing seal may be different , there may be a seal in the rear end tube

- Thread starter

- #46

Your axles should come out this way, tho the bearing seal may be different , there may be a seal in the rear end tube

That would be more than awesome.... If that's the case there wouldn't be a need to crack open the pumpkin, correct? Thanks Jack, appreciate ya! Ray ThumbUp

Jack Klarich

Guest

That would be more than awesome.... If that's the case there wouldn't be a need to crack open the pumpkin, correct? Thanks Jack, appreciate ya! Ray ThumbUp

Correct, look at the pictures on this link

https://www.ebay.com/itm/1427408287...vEBCGMvB-u3ALko9-8toTavQal8dIH7BoCRd4QAvD_BwE

- Thread starter

- #48

Correct

Awesome!! I'm still trying to find those backing plates. Just received an email from Summit Racing stating they don't have a them either. I'm not giving up.... LOL Thanks again. Ray ThumbUp

Why are you wanting new backing plates? That video is about the 9" Ford axle. I looked at your pictures, you have an early 6.75" integral type carrier Ford axle. Used in some Pintos, Mustang IIs, even some early Bronco IIs, Fairmonts, etc. Lehman either shortened the axles or had new axles produced to fit the shortened housings.

Your axles will slip right out once you remove the 4 nuts that secure the backing plates and axle bearing retainers. The Mustang II Organization has a page on this rear axle, with exploded diagram. There actually is a lot of info out there once you search for Ford 6.75 rear axle. Here is a video goes back to 1960-61 Falcon, but those had a different lug pattern. You do not have C-clips holding the axles in.

Your axles will slip right out once you remove the 4 nuts that secure the backing plates and axle bearing retainers. The Mustang II Organization has a page on this rear axle, with exploded diagram. There actually is a lot of info out there once you search for Ford 6.75 rear axle. Here is a video goes back to 1960-61 Falcon, but those had a different lug pattern. You do not have C-clips holding the axles in.

Your axles will slip right out once you remove the 4 nuts that secure the backing plates and axle bearing retainers. The Mustang II Organization has a page on this rear axle, with exploded diagram. There actually is a lot of info out there once you search for Ford 6.75 rear axle. Here is a video goes back to 1960-61 Falcon, but those had a different lug pattern. You do not have C-clips holding the axles in.

Your axles will slip right out once you remove the 4 nuts that secure the backing plates and axle bearing retainers. The Mustang II Organization has a page on this rear axle, with exploded diagram. There actually is a lot of info out there once you search for Ford 6.75 rear axle. Here is a video goes back to 1960-61 Falcon, but those had a different lug pattern. You do not have C-clips holding the axles in.Ok, I see they got bent a little. I'd bend them back, use a 2x4 about 24" long and a C-c;lamp to leverage them back to a proper fit with the drum, then build back your brake shoes / springs / hold downs / etc.

.

.

- Thread starter

- #51

Thank You for all the great information.... appreciate it.

Whay are you wanting new backing plates?

Because all the high contact points for the shoes are gouged as shown in the second picture of post #36. I would rather have new plates than having them repaired and ground down. I don't have a problem having them repaired but, I would have to hire that out. Also, if they are bent, I'm not so sure I could get them straight. They look and feel wider at the top but as I stated earlier on, I never had a problem removing the right side drum. In other words, I never had to forcefully remove the right side.

That video is about the 9" Ford axle.

I was just referencing that video wanting to know if axle removal for my Lehman was the same as shown at the beginning. I'm not a mechanic therefore, I'm asking those of you that know one way or the other.

I looked at your pictures, you have an earl 6.75" integral type carrier Ford axle. Used in some Pintos, Mustang IIs, even some early Bronco IIs, Fairmonts, etc.

You're correct, they're are many Fords that used thes axles back in the 70's and 80's.

Lehman either shortened the axles or had new axles produced to fit the shortened housings.

The following link is probably the best info. you'll find anywhere in regards to Lehman rear ends. Especially, (RIP) Jim Murphys answer in post #2

https://www.triketalk.com/forum/threads/56158-Question-for-Lee-Mann-drive-axle-replacement-parts

Your axles will slip right out once you remove the 4 nuts that secure the backing plates and axle bearing retainers. The Mustang II Organization has a page on this rear axle, with exploded diagram. There actually is a lot of info out there once you search for Ford 6.75 rear axle. Here is a video goes back to 1960-61 Falcon, but those had a different lug pattern. You do not have C-clips holding the axles in.

I will definitely check it all out. appreciate the help.

Thanks again for all the info. Ray. ThumbUp

- Thread starter

- #52

Ok, I see they got bent a little. I'd bend them back, use a 2x4 about 24" long and a C-c;lamp to leverage them back to a proper fit with the drum, then build back your brake shoes / springs / hold downs / etc.

.

Thanks.... That may work. I know I need to be careful simply due to these backing plates are impossible to find other than some used one's. Thanks again. Ray ThumbUp

- Thread starter

- #53

The 4 nuts viewed thru the holes on the flange of the axle, remove them, you may need to put the drum on backwards with 2 nuts and use like a slide hammer to pop the axles out

No need to worry about gears falling out with this type of rear end ( only with C clip type rear

ends) you need to use caution

Now with axles out look in the axle tube at the grease seal, if it is overly wet and grease build up outside the seal replace seal, be sure to lube the lip of the seal

Thanks again Jack... This may be a stupid question......LOL. Should I drain the differential fluid before I pull the axle. I do have the rear end up on jacks slightly higher than my ramps. I just changed it prior to the brake shoe install but, of course I will drain it if needed. Thanks again. Clueless Ray (Headbang)

Jack Klarich

Guest

Thanks again Jack... This may be a stupid question......LOL. Should I drain the differential fluid before I pull the axle. I do have the rear end up on jacks slightly higher than my ramps. I just changed it prior to the brake shoe install but, of course I will drain it if needed. Thanks again. Clueless Ray (Headbang)

Very little grease would run out if any

- Thread starter

- #55

Very little grease would run out if any

Thanks Jack... I'll be pulling the axles either today or tomorrow. Once I get the backing plates off, I'm going to check around a couple welding shops near me to see if they'll repair those grooves on the nubs. I'll give them a shoe for double checking across them for contact. In addition, I'll definitely check for the trueness to see if they are bent or not the best I can. Thanks again, appreciate ya big time for seeing me through this! Ray ThumbUp

Jack Klarich

Guest

Thanks Jack... I'll be pulling the axles either today or tomorrow. Once I get the backing plates off, I'm going to check around a couple welding shops near me to see if they'll repair those grooves on the nubs. I'll give them a shoe for double checking across them for contact. In addition, I'll definitely check for the trueness to see if they are bent or not the best I can. Thanks again, appreciate ya big time for seeing me through this! Ray ThumbUp

Just for grins, as you have the shoes off and will be pulling the plates, pop the wheel cylinders apart and look in the bores, check the pistons for scoring.

Keep in mind new parts can easily not be OK, I have seen this many times before

I once got a spark plug with no threads

- Thread starter

- #57

Just for grins, as you have the shoes off and will be pulling the plates, pop the wheel cylinders apart and look in the bores, check the pistons for scoring.

Keep in mind new parts can easily not be OK, I have seen this many times before

I once got a spark plug with no threads

Thanks! Great idea.... I will definitely do that. It's so true, parts today are no where near how they used to be in quality. Spark plug with no threads.... wow, never heard of that one but, sooo believable. Thanks again! Ray

- Thread starter

- #58

Just for grins, as you have the shoes off and will be pulling the plates, pop the wheel cylinders apart and look in the bores, check the pistons for scoring.

Keep in mind new parts can easily not be OK, I have seen this many times before

I once got a spark plug with no threads

Took apart the wheel cylinders, all looks great.... Pulled both axles with the left one needing to use the reverse drum trick as a hammer a couple times. After removing the backing plate bolts I gave both axles an up/down and side to side test. No play at all, nice and solid. As for the seals, they also look good.

After cleaning up the axles, I placed them back with the exception of bolting them in just to keep them off the floor.

I have a question since I'm a little.... well probably more... oblivious.

Jack Klarich

Guest

Took apart the wheel cylinders, all looks great.... Pulled both axles with the left one needing to use the reverse drum trick as a hammer a couple times. After removing the backing plate bolts I gave both axles an up/down and side to side test. No play at all, nice and solid. As for the seals, they also look good.

After cleaning up the axles, I placed them back with the exception of bolting them in just to keep them off the floor.

I have a question since I'm a little.... well probably more... oblivious.With the trike being in neutral, I noticed something odd but, there must be a reason. As I was spinning the axle, I noticed the other side spinning in the opposite direction. After you're done laughing.....LOL. Please fill me in. :Trike1: Thanks Jack. Ray

Ray, that is an open rear end, one of the most popular on the road

Each axle can turn independant of the other

- Thread starter

- #60

Ray, that is an open rear end, one of the most popular on the road

Each axle can turn independant of the other

Thanks Jack.... Great answer! I just took my backing plates to a welder to fill the grooves with the hardest weld they have. They're also going to grind them down. I gave them a pair of shoes for flush checking as well. In addition, I gave them a drum to check against the flushness around the plates. They told me they have some straight edges that they'll use as well. I straightened them somewhat with a couple big C-clamps and flat bar but, it could use a litte more. They told me that they had a press which would do the job and to give them a couple days. (Sweating) (Worried) So far we're rolling to get this done.... Thanks again, appreciate ya!! Ray ThumbUp

Similar threads

- Replies

- 12

- Views

- 43,169