peteg59

Meme Master

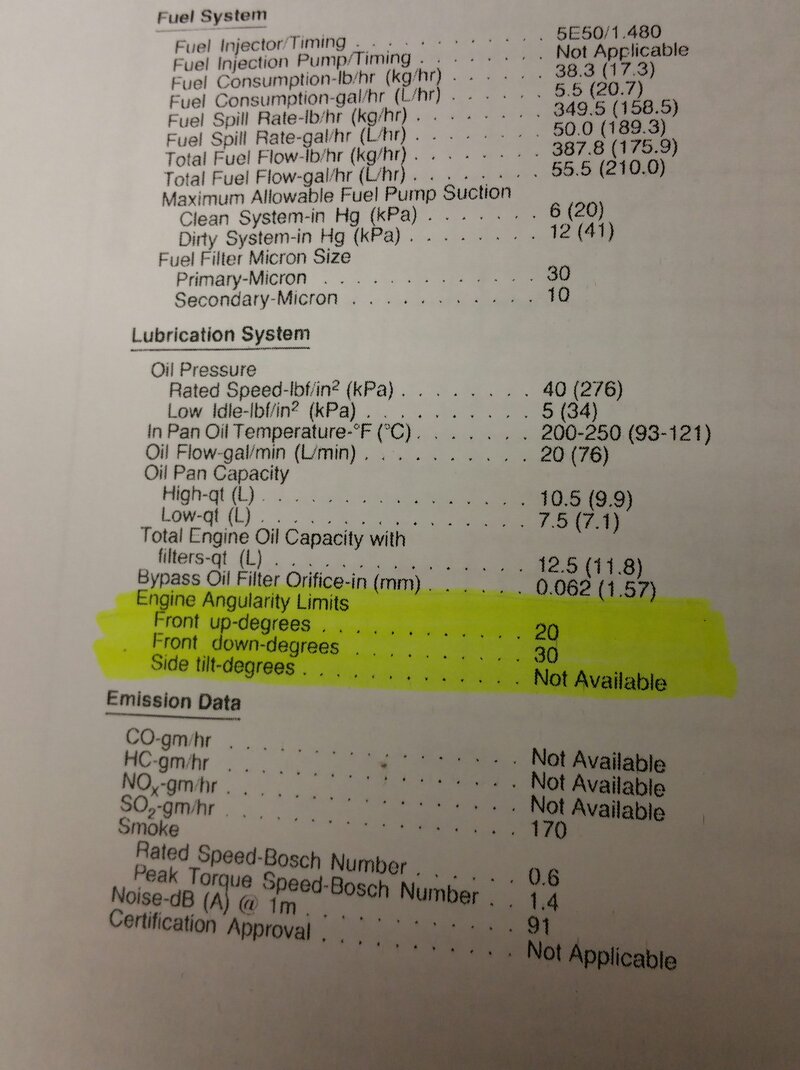

It will be interesting to hear if the angle will be an issue.

I'm nowhere near an engineer however I would think as long as the pickup tube can get a good & continuous oil supply from the pan, its good?

Theres no float level to worry about as you would have in a carb, and the fuel pump/injectors can typically run at fairly extreme angles before starving out, so what else is there to consider in a diesel powered trike besides looks?

I'm nowhere near an engineer however I would think as long as the pickup tube can get a good & continuous oil supply from the pan, its good?

Theres no float level to worry about as you would have in a carb, and the fuel pump/injectors can typically run at fairly extreme angles before starving out, so what else is there to consider in a diesel powered trike besides looks?