- Thread starter

- #332

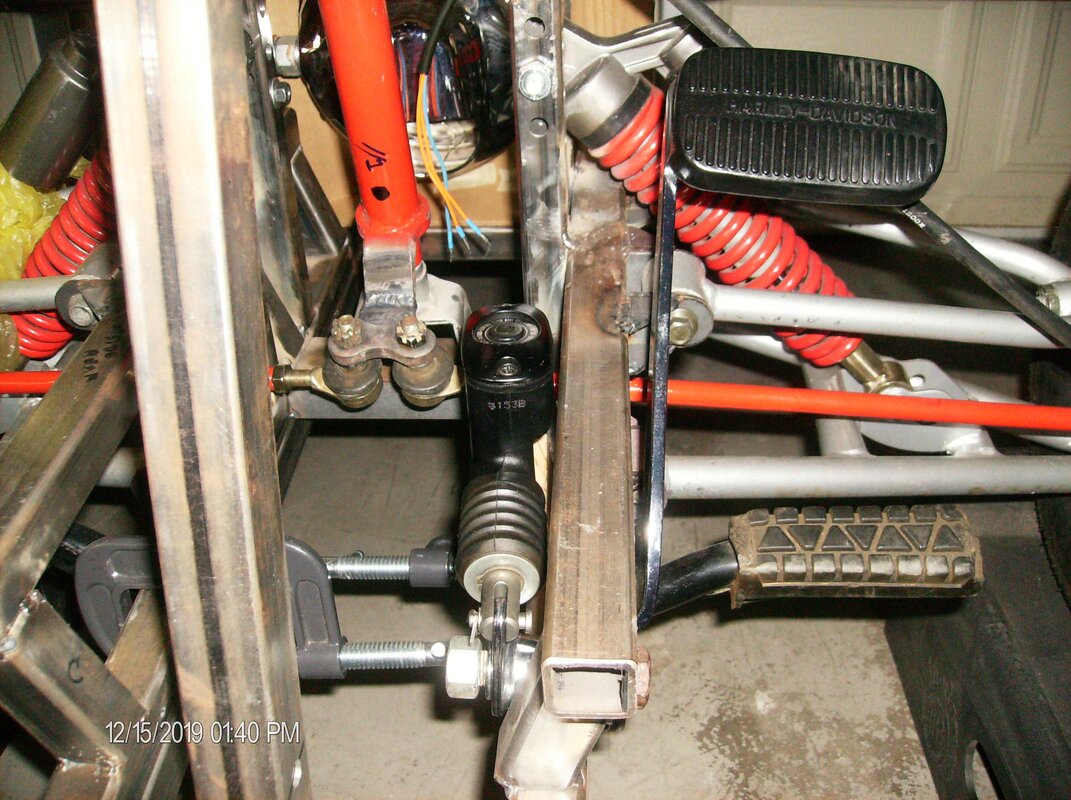

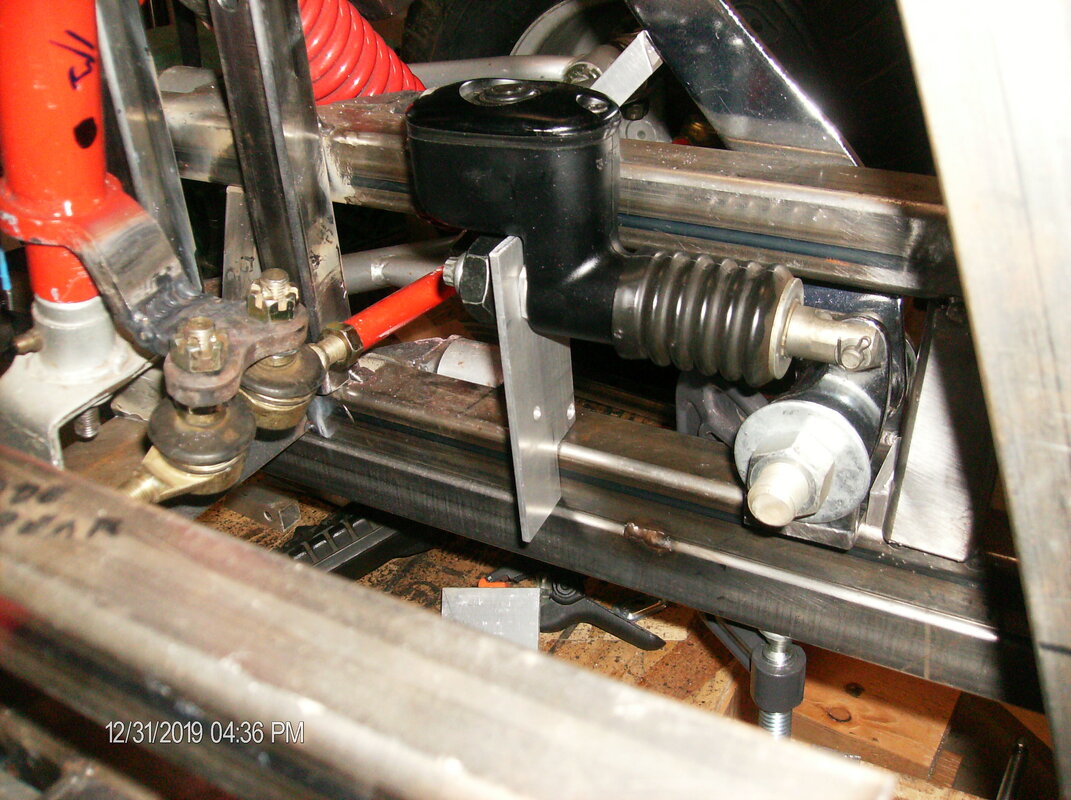

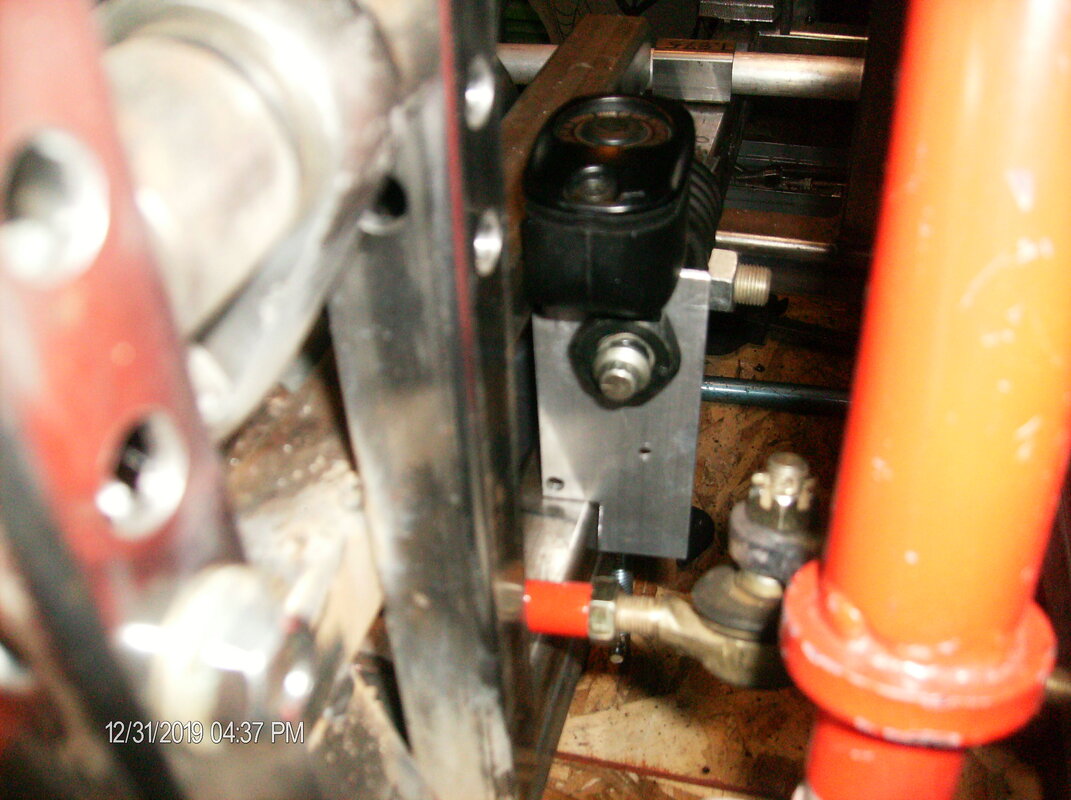

Caliper Bracket Mount For Harley FXSTS

[FONT=Verdana,Arial,Tahoma,Calibri,Geneva,sans-serif]M-C Caliper Bracket Mount For Harley FXSTS, polished $99.89?[/FONT]

[FONT=Verdana,Arial,Tahoma,Calibri,Geneva,sans-serif]M-C Caliper Bracket Mount For Harley FXSTS, polished $99.89?[/FONT]

Thank you Stace, BUT, I am learning so much about motorcycle parts and how they work in unison to other parts. After thought, IF that slot was angled towards the axle hole it would work (chain adjust movement) So I might be better off with a setup like a springer disc uses? or?

[FONT=Verdana,Arial,Tahoma,Calibri,Geneva,sans-serif]M-C Caliper Bracket Mount For Harley FXSTS, polished $99.89?[/FONT]

[FONT=Verdana,Arial,Tahoma,Calibri,Geneva,sans-serif]M-C Caliper Bracket Mount For Harley FXSTS, polished $99.89?[/FONT]