- Moderator

- #1

I ran into a buddy a couple weeks back at a Meet and Greet in Custer, SD. He recently acquired a used Goldwing with a Viper conversion and we began discussing each other's. He mentioned about his getting a pinion seal leak and having to replace his pinion seal because of the leak and asked if I had any issues with mine. I'm at 6 years since I had my conversion done and hadn't noticed any issues. He took a peek where driveshaft goes in to the rear end and said he can see where there was a dirty film build up and that mine will probably need to be replaced in the near future.

I had taken my trike out there in my toyhauler and didn't notice any drips on floor. I did probably over 1000 miles total on trip and still no drips. Even after getting back home and unloading, still the toyhauler floor was dry. Since the trip, I have driven it another 7-800 miles and now I'm seeing drips on garage floor. I looked underneath and can see the plate under the differential is wet with gear oil. So the next step is to get to the pinion seal and tackle this.

The only thing I've done to rear end recently was to replace the gear oil prior to the trip out west. I followed the CSC recommendation and used a conventional gear oil. The one I used was Castrol Limited Slip 80W-90 and it also was API GL-5 rated so it should have been fine.

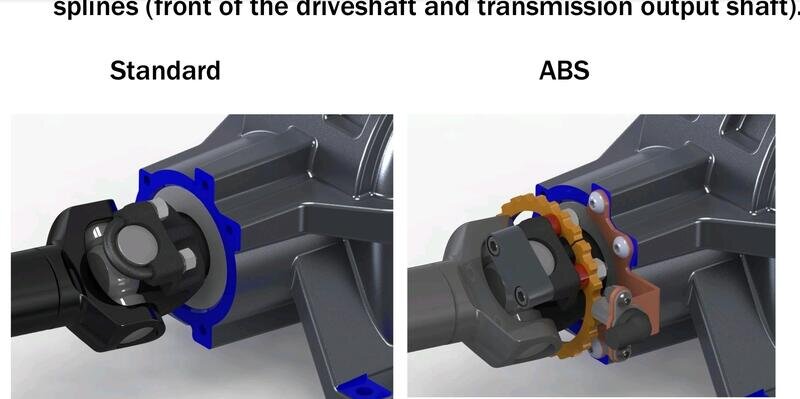

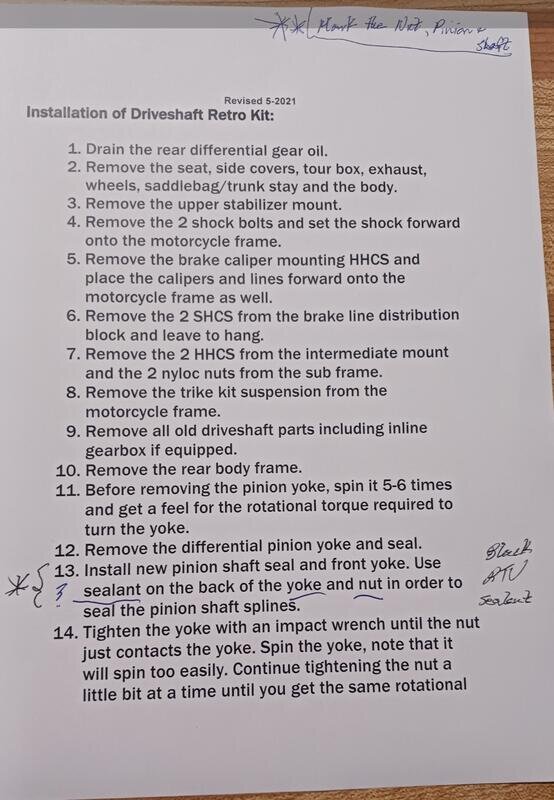

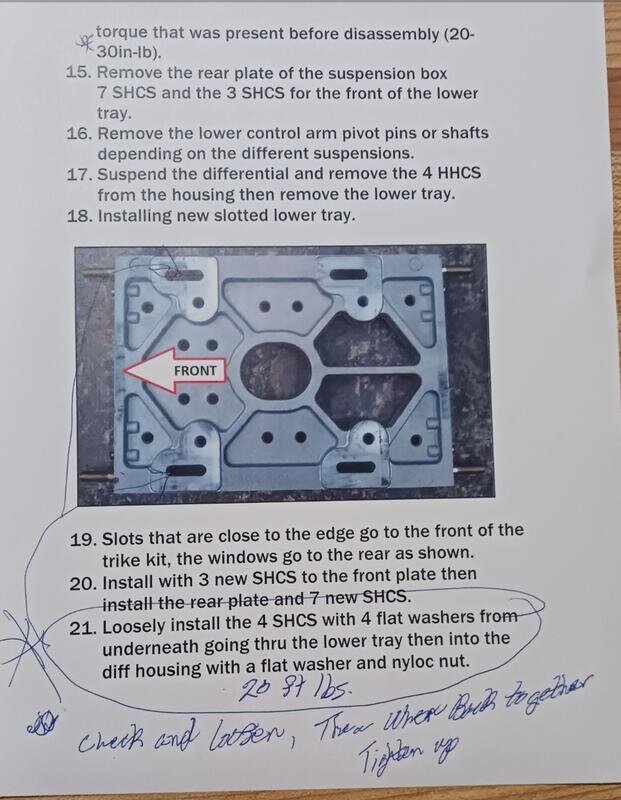

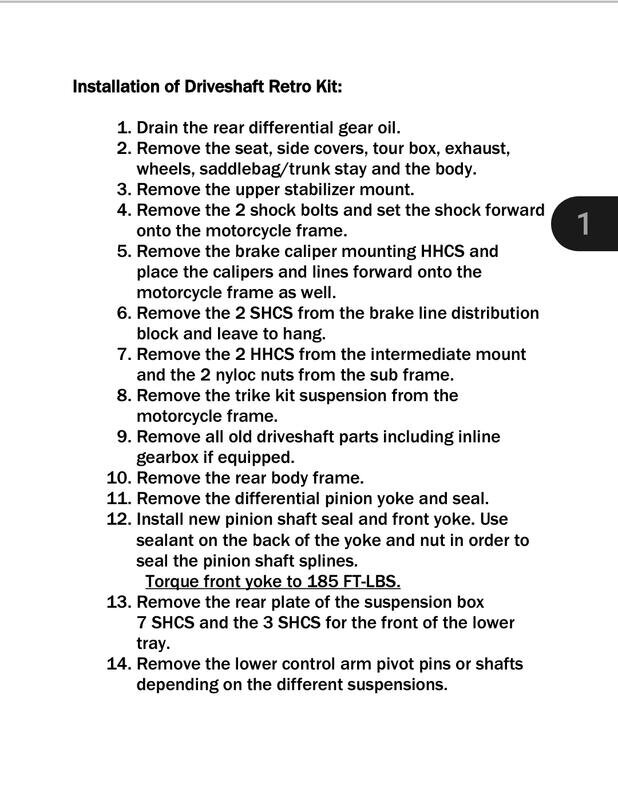

I will be calling CSC in the morning to order the seal. My buddy mentioned that a special tool is needed for the seal which he bought and is going to loan to me to use. But I was wondering if maybe I can source the seal locally. I seem to remember the installer mentioning something about the rear end on my 2016 Viper being a modified Dana (Chrysler possibly?) rear end but not sure. Also does anyone have any tips and clues about doing the pinion seal replacement? Any help would be greatly appreciated...

I had taken my trike out there in my toyhauler and didn't notice any drips on floor. I did probably over 1000 miles total on trip and still no drips. Even after getting back home and unloading, still the toyhauler floor was dry. Since the trip, I have driven it another 7-800 miles and now I'm seeing drips on garage floor. I looked underneath and can see the plate under the differential is wet with gear oil. So the next step is to get to the pinion seal and tackle this.

The only thing I've done to rear end recently was to replace the gear oil prior to the trip out west. I followed the CSC recommendation and used a conventional gear oil. The one I used was Castrol Limited Slip 80W-90 and it also was API GL-5 rated so it should have been fine.

I will be calling CSC in the morning to order the seal. My buddy mentioned that a special tool is needed for the seal which he bought and is going to loan to me to use. But I was wondering if maybe I can source the seal locally. I seem to remember the installer mentioning something about the rear end on my 2016 Viper being a modified Dana (Chrysler possibly?) rear end but not sure. Also does anyone have any tips and clues about doing the pinion seal replacement? Any help would be greatly appreciated...