- Thread starter

- Moderator

- #31

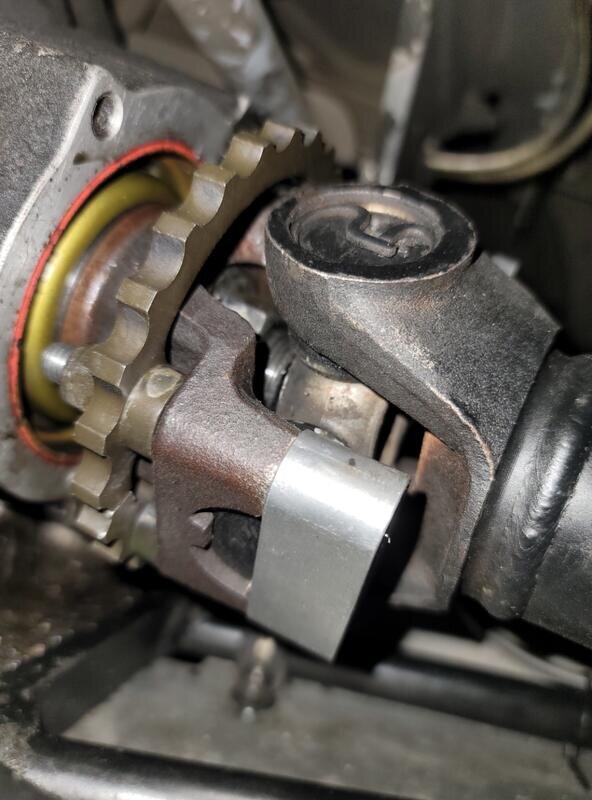

Ok, I got some clarification from Will. Sealant does go on the back of the nut. As far as back of the yoke, a bead of sealant should go not on the back "face" but on the chamfered rear section by where the yoke splines are. The sealant will then get spread between the yoke splines and pinion shaft splines to seal it so that between sealant on back of nut and in the splunes, no oil can escape. The rubber part on the seal should match up with the smooth back outside of yoke and that should prevent any gear oil from leaking that way. I think I will still put a little gear oil on that just for good measure.

I also asked about the importance of the positioning of the yoke on the shaft because I didn't mark any of that prior to removal. I was told that it really doesn't matter, just put it back on and I should be good.

I also asked about the shaft seal and how far it should be installed. I mentioned I was finally able to get it flush with the face of the rear end and was told that's exactly where it should be.

I'm glad I'm finally headed in the right direction.

I also asked about the importance of the positioning of the yoke on the shaft because I didn't mark any of that prior to removal. I was told that it really doesn't matter, just put it back on and I should be good.

I also asked about the shaft seal and how far it should be installed. I mentioned I was finally able to get it flush with the face of the rear end and was told that's exactly where it should be.

I'm glad I'm finally headed in the right direction.