Here is the deal with the Cragars....

The bolt pattern on H-D trike rear wheels is 4x4.25". Stock Harley trike rear wheels are 15x5.5" with 2.85" backspacing. The Cragar I am using (15/14 SS) has a backspacing of 4.5”. My adapter is from Wheel Adapters USA and is a 4x4.25 to 5x4.5 adapter 2” thick with a 12x1.5 lug thread. So the Cragar at 4.5” backspace with a 2” adapter nets out at 2.5” backspacing and is very nearly equal to the stock Harley back space. Since I am fabricating the fenders... it all works well.

But......

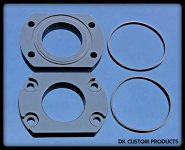

Your wheel adapter MUST have a centering hub. Either built in or made for the purpose. I turned one down and made the insert for mine. The classic SS series has slotted holes and that means your (safe) installation relies on the centering hub to install the wheel. See below

View attachment 59173

View attachment 59174

You will get two sets of washers with the Cragars.... Use the offset hole washers to hold everything in place

View attachment 59175

I have them bolted onto the wheels right now. When the fenders come off and I install the tires, I will get some detail photos to share.

Good Luck with your build!

That must be an ol' school Cragar type thing. I did not have any problems with the 18X9's I used.