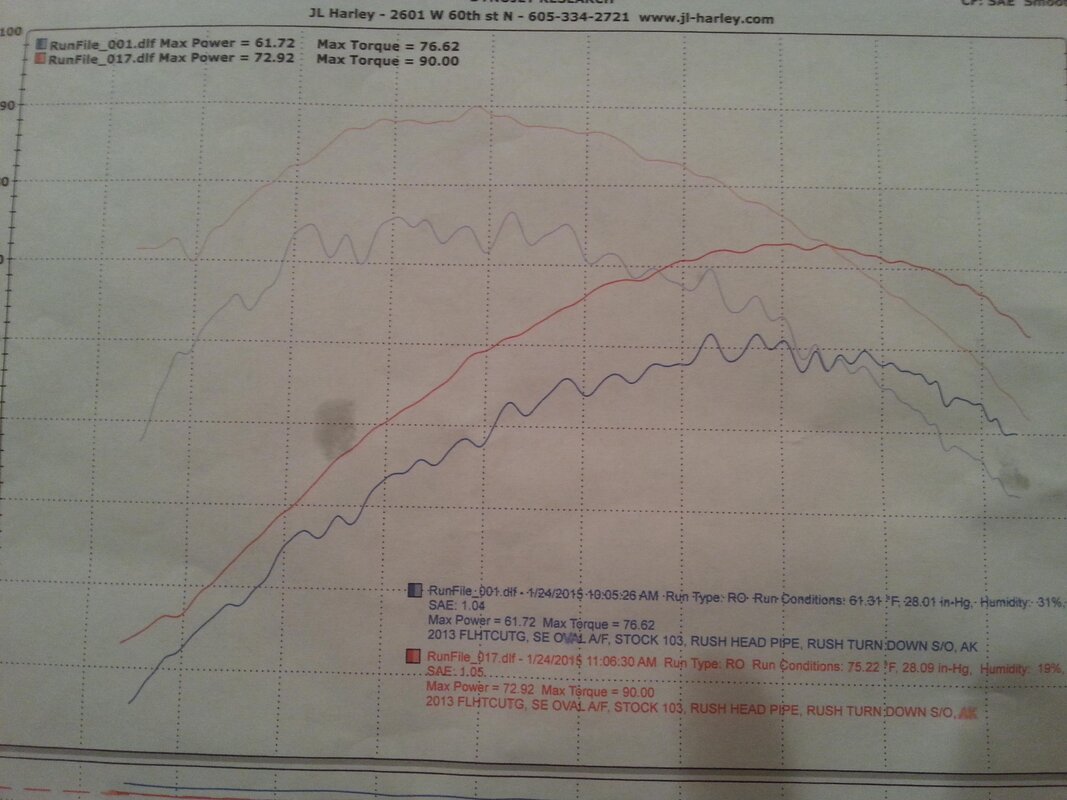

Just got back from getting my trike dyno'd. I installed the Screamin' Eagle Ventilator air cleaner and Rush Eco headpipes and then hauled it to the dealer 3 hours away to put on the race tuner and then dyno. Run before the tune was 61.7hp and 76.6 torque. Not sure how these compare to bone stock. After the tune it had 72.9hp and 90.0 torque. That is a 18% increase in horsepower and 17.5% torque. I can't wait to take it for a ride. It was 42* with a light rain so I didn't want to test ride at the dealership.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tuned the Tri-Glide

- Thread starter y2k_harley

- Start date

- Thread starter

- #3

2013

- Moderator

- #4

Good numbers you will be pleased the the performance2013

DK Custom Products

Sponsor

Yes, those are pretty good numbers for a Stage I on your '13.

Important thing is, where is the torque? What RPM?

Here's a pic of the Performance Plus Stage I on my '11 TG.

You can see the torque peaks a little past 3500 RPM, but it is nice and strong, even down a bit below 3000 RPM.

A flatter torque curve is more desirable, but on the pre-14's, that is most easily accomplished with some non-epa cams.

But, paraphrasing Gorilla, you should have some fun with that nice bump in power.

Kevin

Important thing is, where is the torque? What RPM?

Here's a pic of the Performance Plus Stage I on my '11 TG.

You can see the torque peaks a little past 3500 RPM, but it is nice and strong, even down a bit below 3000 RPM.

A flatter torque curve is more desirable, but on the pre-14's, that is most easily accomplished with some non-epa cams.

But, paraphrasing Gorilla, you should have some fun with that nice bump in power.

Kevin

Just got back from getting my trike dyno'd. I installed the Screamin' Eagle Ventilator air cleaner and Rush Eco headpipes and then hauled it to the dealer 3 hours away to put on the race tuner and then dyno. Run before the tune was 61.7hp and 76.6 torque. Not sure how these compare to bone stock. After the tune it had 72.9hp and 90.0 torque. That is a 18% increase in horsepower and 17.5% torque. I can't wait to take it for a ride. It was 42* with a light rain so I didn't want to test ride at the dealership.

That should be a noticeable improvement. If you have a dyno sheet maybe you can post it. One thing you'll notice is how much smoother it will run. I wouldn't get to hung up on a dyno sheet, you can't ride a dyno, they're a good tool for tuning but they are variable. I've always felt a tune is a success when it runs smoother, cooler and you feel it in the seat of your pants.

DK Custom Products

Sponsor

That should be a noticeable improvement. If you have a dyno sheet maybe you can post it. One thing you'll notice is how much smoother it will run. I wouldn't get to hung up on a dyno sheet, you can't ride a dyno, they're a good tool for tuning but they are variable. I've always felt a tune is a success when it runs smoother, cooler and you feel it in the seat of your pants.

:Agree:

Kevin

- Thread starter

- #8

I do have the dynosheet. Peak torque was right around 3500 rpms. It was fairly flat from 2500 - 4000. I noticed they dyno graph was almost a smooth line after the tune, where as before looked more like a heartbeat. Looking forward to the decrease in heat also. A/F ratios before the tune (with pipes and air cleaner installed) were 13:1 or a little higher. After the tune they looked about 11.25:1 or so.

That's way rich. Are you sure that is what it is ?

- Thread starter

- #10

That should be a noticeable improvement. If you have a dyno sheet maybe you can post it. One thing you'll notice is how much smoother it will run. I wouldn't get to hung up on a dyno sheet, you can't ride a dyno, they're a good tool for tuning but they are variable. I've always felt a tune is a success when it runs smoother, cooler and you feel it in the seat of your pants.

:Agree:

Roger

You are correct. I looked again and it is about 13:1 after the tune versus 15:1 or a little higher before.

- - - Updated - - -

View attachment 24812

Are you sure it is 13.1:1?? I didn't think the OEM narrow band O2 sensors would read anything lower than (I believe) 14.2:1. I could be in error, but I will be re-searching that. I am not sure where I read that but will review.

I do know that when I had my 2007 Fatboy dynoed, back in 07 with a Power Commander III, the tuner's target was 13.1:1. But the PC III cam with O2 sensor eliminators. Therefore I would think that if you intend for your OEM narrow band sensors to do their job you would need your AFR to be 14.2:1 or higher!!??

Maybe someone else can offer better more substantiated info/data on this!!

Roger

Roger

You are correct about the O2's not reading that AFR, but the ECM can also operate in open mode without the benefit of the O2's reading.Are you sure it is 13.1:1?? I didn't think the OEM narrow band O2 sensors would read anything lower than (I believe) 14.2:1. I could be in error, but I will be re-searching that. I am not sure where I read that but will review.

I do know that when I had my 2007 Fatboy dynoed, back in 07 with a Power Commander III, the tuner's target was 13.1:1. But the PC III cam with O2 sensor eliminators. Therefore I would think that if you intend for your OEM narrow band sensors to do their job you would need your AFR to be 14.2:1 or higher!!??

Maybe someone else can offer better more substantiated info/data on this!!

Roger

Roger

Are you sure it is 13.1:1?? I didn't think the OEM narrow band O2 sensors would read anything lower than (I believe) 14.2:1. I could be in error, but I will be re-searching that. I am not sure where I read that but will review.

I do know that when I had my 2007 Fatboy dynoed, back in 07 with a Power Commander III, the tuner's target was 13.1:1. But the PC III cam with O2 sensor eliminators. Therefore I would think that if you intend for your OEM narrow band sensors to do their job you would need your AFR to be 14.2:1 or higher!!??

Maybe someone else can offer better more substantiated info/data on this!!

Roger

Roger

You are correct, the factory narrow band sensors can't read that rich. Most tuning centers use wide band sensors or 5 gas analyzer to tune by, the person tuning the engine will normally target an open loop AFR to calibrate his VE tables which keeps the factory narrow bands from controlling anything during the tune. Once the tune is complete they will then set which areas they want in closed loop.

The AFR reading on the dyno chart is coming from either blocks with wide band O2 sensors mounted on the head pipes, they drill a small hole in the head pipe and install what they call a rivenut to mount the block too. Once they are done tuning they remove the blocks and put a bolt in the insert they had placed in the head pipe, it is then hidden under the heat shield. They also can use a piece of stainless tubing connected to a vac pump with a wide band O2 sensor in it which is run through the muffler and into the head pipe of the front or rear cylinder, or a 5 gas analyzer which also normally gets it sample via a piece of tubing into the head pipe.

Similar threads

- Replies

- 5

- Views

- 8,406

- Replies

- 1

- Views

- 6,735

- Replies

- 7

- Views

- 33,786