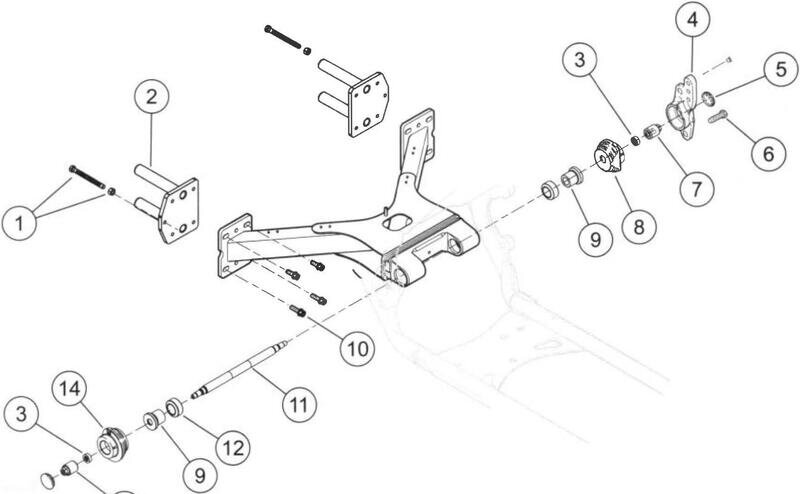

At 20,000 miles the manual says to check the Rear Fork Pivot Shaft Lock Nut Torque. The torque value says 50 ft-lbs first torque. It follows that with "Torque: (180 ° ) Rear fork pivot shaft locknut, final torque"

What are they talking about?

What are they talking about?