dadztoy

300+ Posts

Hi folks,

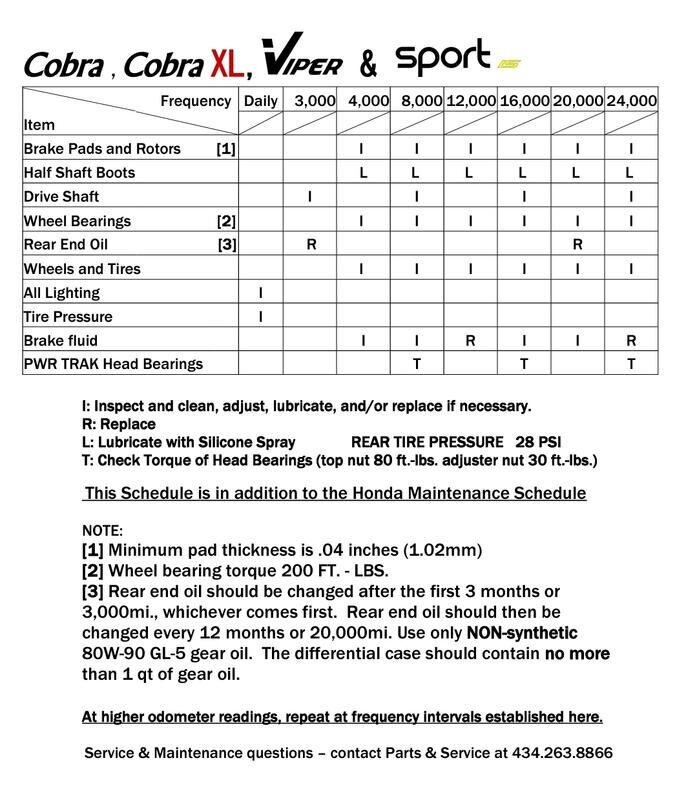

I have a 2009 Navi/ABS wing with a 2021 CSC Cobra XL conversion. I do have a 6 degree rake kit on it, but I am still not satisfied with the amount of steering effort required in turns.

I have the head bearings adjusted to the recommended 35 lb ft of torque. What would be the effects of torqueing to say 40 lb ft or perhaps 25 lb ft?

The standard Gen 1 head bearing torque on a non converted bike is 21 lb ft, so I am curious as to why and how the 35 lb ft measurement was obtained recommended.

As previously mentioned, I am trying to obtain easier steering effort in turns with the 6 degree rake kit. I understand the theory behind the 21 lb ft on a non-converted bike, but I am looking for guidance and cause and effect on a trike in relation to the recommended 35 lb ft of head bearing torque. Would more or less head bearing torque result in less steering effort or increased steering effort and would it be detrimental to the operation and/or longevity of the head bearings other aspect of the of the trike.

As always, thanks in advance, all responses appreciated.

Les

I have a 2009 Navi/ABS wing with a 2021 CSC Cobra XL conversion. I do have a 6 degree rake kit on it, but I am still not satisfied with the amount of steering effort required in turns.

I have the head bearings adjusted to the recommended 35 lb ft of torque. What would be the effects of torqueing to say 40 lb ft or perhaps 25 lb ft?

The standard Gen 1 head bearing torque on a non converted bike is 21 lb ft, so I am curious as to why and how the 35 lb ft measurement was obtained recommended.

As previously mentioned, I am trying to obtain easier steering effort in turns with the 6 degree rake kit. I understand the theory behind the 21 lb ft on a non-converted bike, but I am looking for guidance and cause and effect on a trike in relation to the recommended 35 lb ft of head bearing torque. Would more or less head bearing torque result in less steering effort or increased steering effort and would it be detrimental to the operation and/or longevity of the head bearings other aspect of the of the trike.

As always, thanks in advance, all responses appreciated.

Les