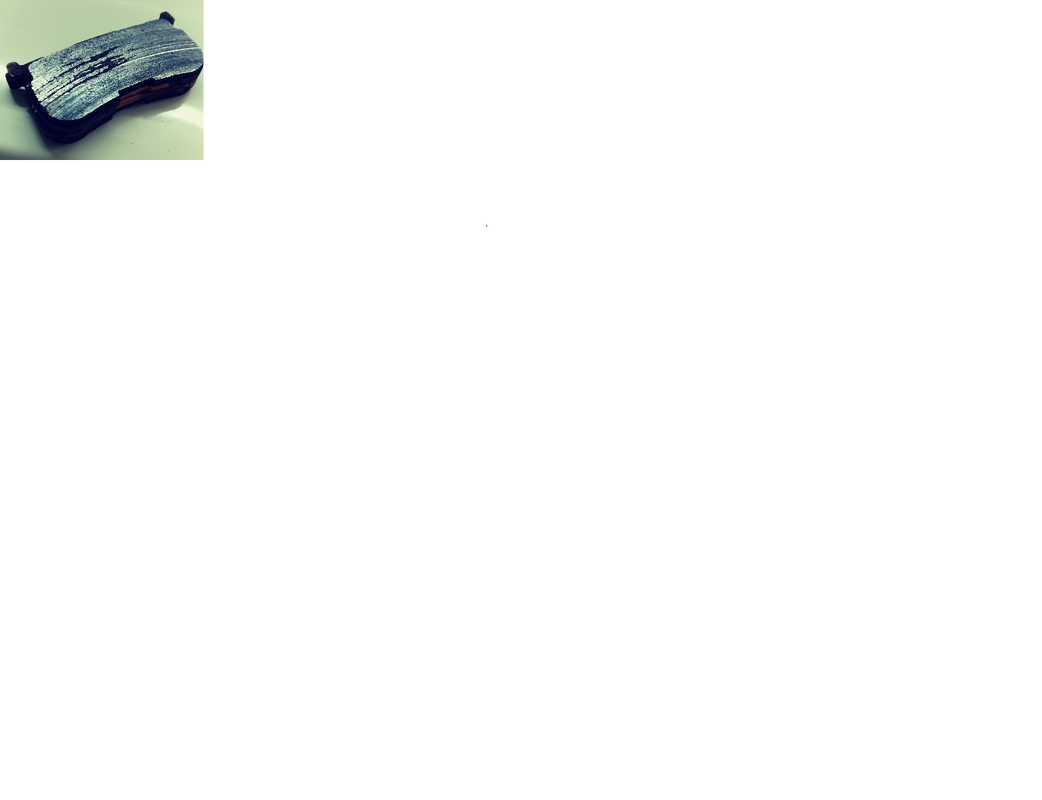

I am in the process of upgrading my all of my brake pads to EBC HH on my 2014 TriGlide. As I was checking the rotors I noticed that the left rear rotor has some small grooves in it on the inside surface. The trike only has about 8K on it so I was surprised to see this. The cause is unknown at this point, but I will be giving the e-brake a close look and readjustment as part of the upgrade process. I bought the trike used so who knows what happened in its previous life.

Here's my question - should I replace the rotor, have it resurfaced, or just let it pass? The six or seven grooves are very narrow (about a finger nail's thickness) and shallow (deepest is about .004") and are only in the middle of the surface, but noticeable to the touch. A new rotor (p/n 41500031) is about $150 from Surdyke. I am tempted to just leave them be, but I don't want to be penny wise and pound foolish.

(And, for those of you curious as to why I would be upgrading from stock, I pull a Lee-sure Lite on long trips and want the added stopping power with no fade. In the past I upgraded to EBC sintered pads on my '07 Ultra and EBC red stuff pads on my 2012 Corvette with markedly improved braking performance on both.)

Thanks,

Gary

Here's my question - should I replace the rotor, have it resurfaced, or just let it pass? The six or seven grooves are very narrow (about a finger nail's thickness) and shallow (deepest is about .004") and are only in the middle of the surface, but noticeable to the touch. A new rotor (p/n 41500031) is about $150 from Surdyke. I am tempted to just leave them be, but I don't want to be penny wise and pound foolish.

(And, for those of you curious as to why I would be upgrading from stock, I pull a Lee-sure Lite on long trips and want the added stopping power with no fade. In the past I upgraded to EBC sintered pads on my '07 Ultra and EBC red stuff pads on my 2012 Corvette with markedly improved braking performance on both.)

Thanks,

Gary