- Thread starter

- #61

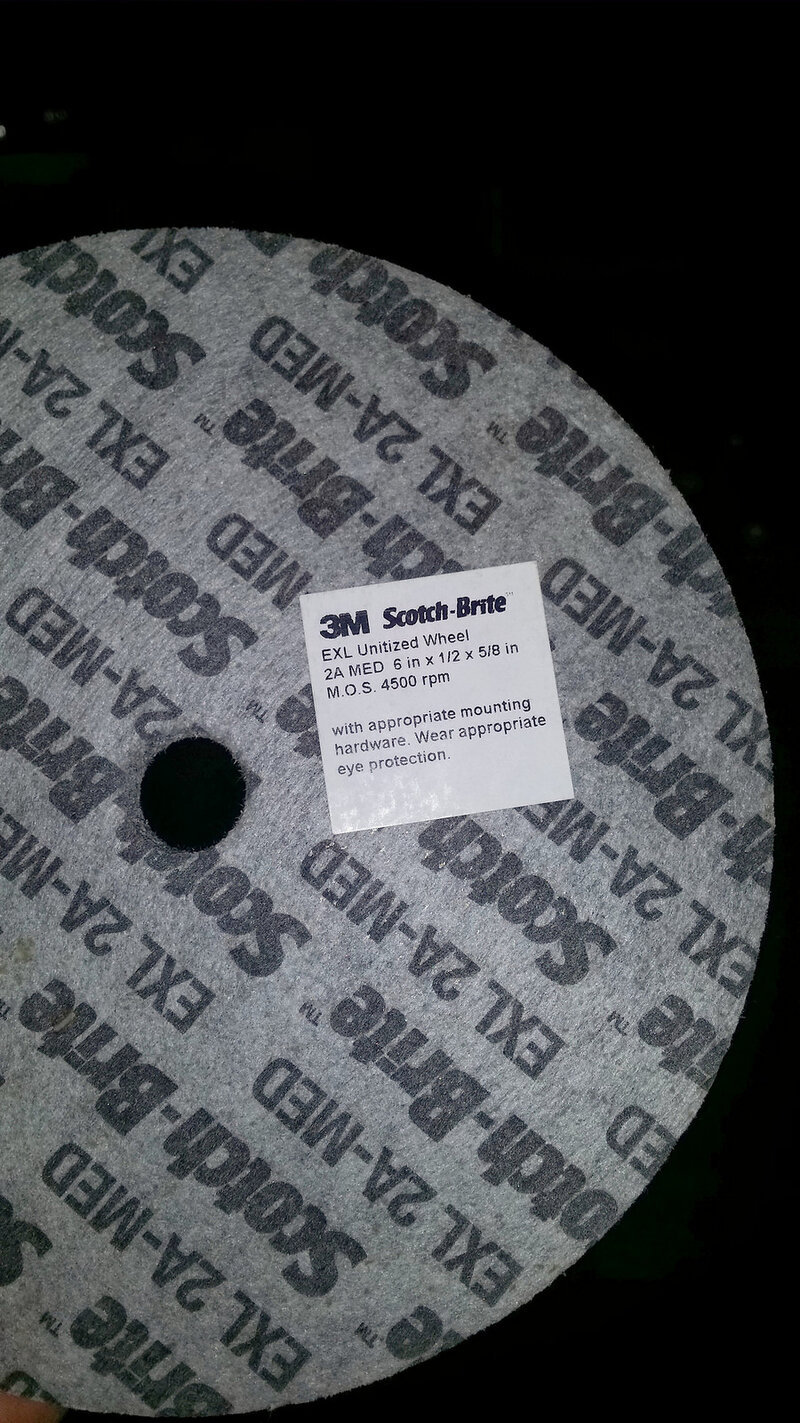

Okay I do have the series of wet/dry paper needed, I had just been doing dry up to this point, but I just do not know when it is good enough to really finish out, guess not a time to be a perfectionist.

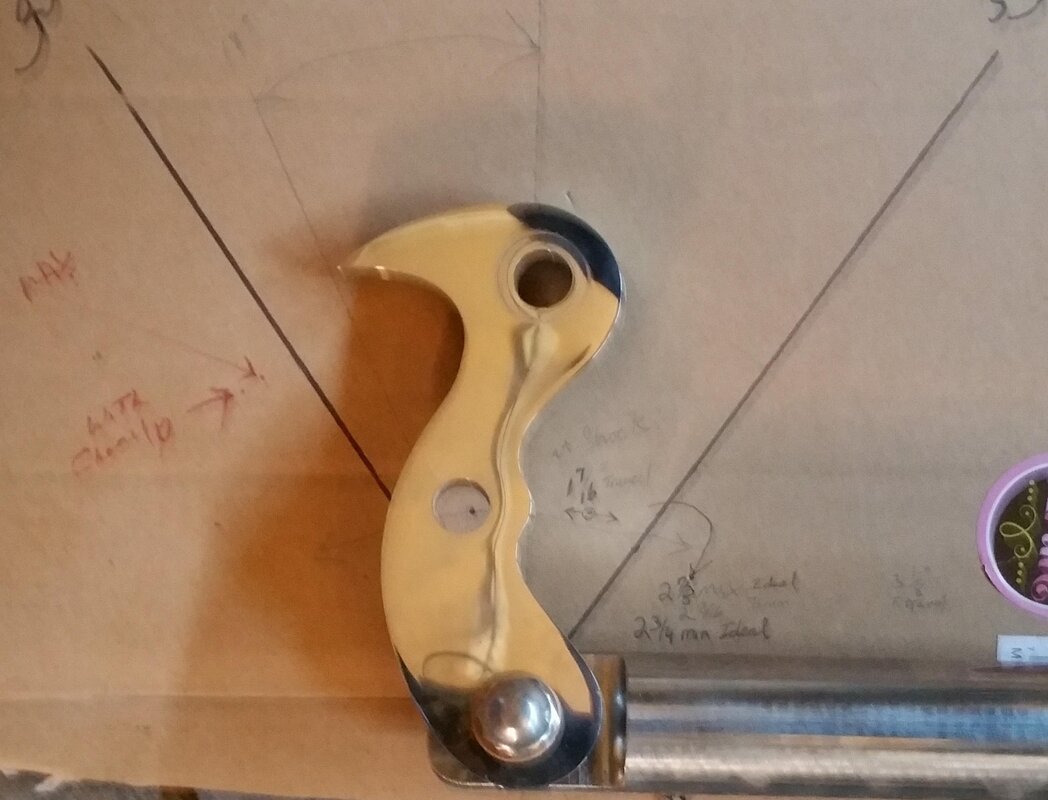

Now does one work the metal and remove the mill finish before doing a pattern and cutting it out ?

I ask because that is what I started doing with the rocker plates. I actually have done those by hand with 80 grit on the block, but a few pass with the 50grit (correction as it was what I bought not 40 ) on the Vibrating sander, LOL, another correction as no one calls them shuffle sanders. Do not ask where that came from, still trying to figure it out.

Have to help the neighbor this morning, maybe I can get something else done in the day.

Be good and ride safe everyone.

Now does one work the metal and remove the mill finish before doing a pattern and cutting it out ?

I ask because that is what I started doing with the rocker plates. I actually have done those by hand with 80 grit on the block, but a few pass with the 50grit (correction as it was what I bought not 40 ) on the Vibrating sander, LOL, another correction as no one calls them shuffle sanders. Do not ask where that came from, still trying to figure it out.

Have to help the neighbor this morning, maybe I can get something else done in the day.

Be good and ride safe everyone.