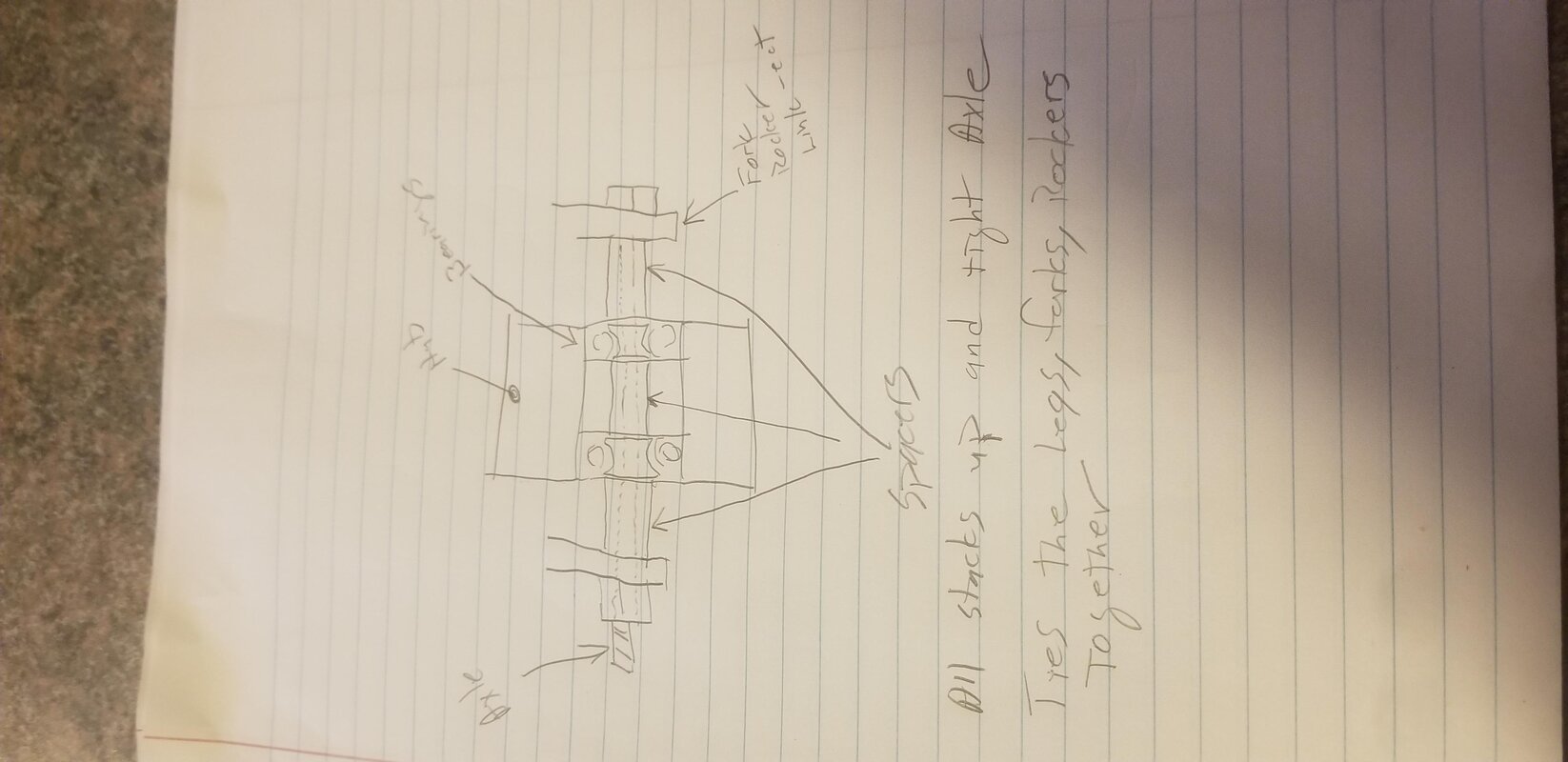

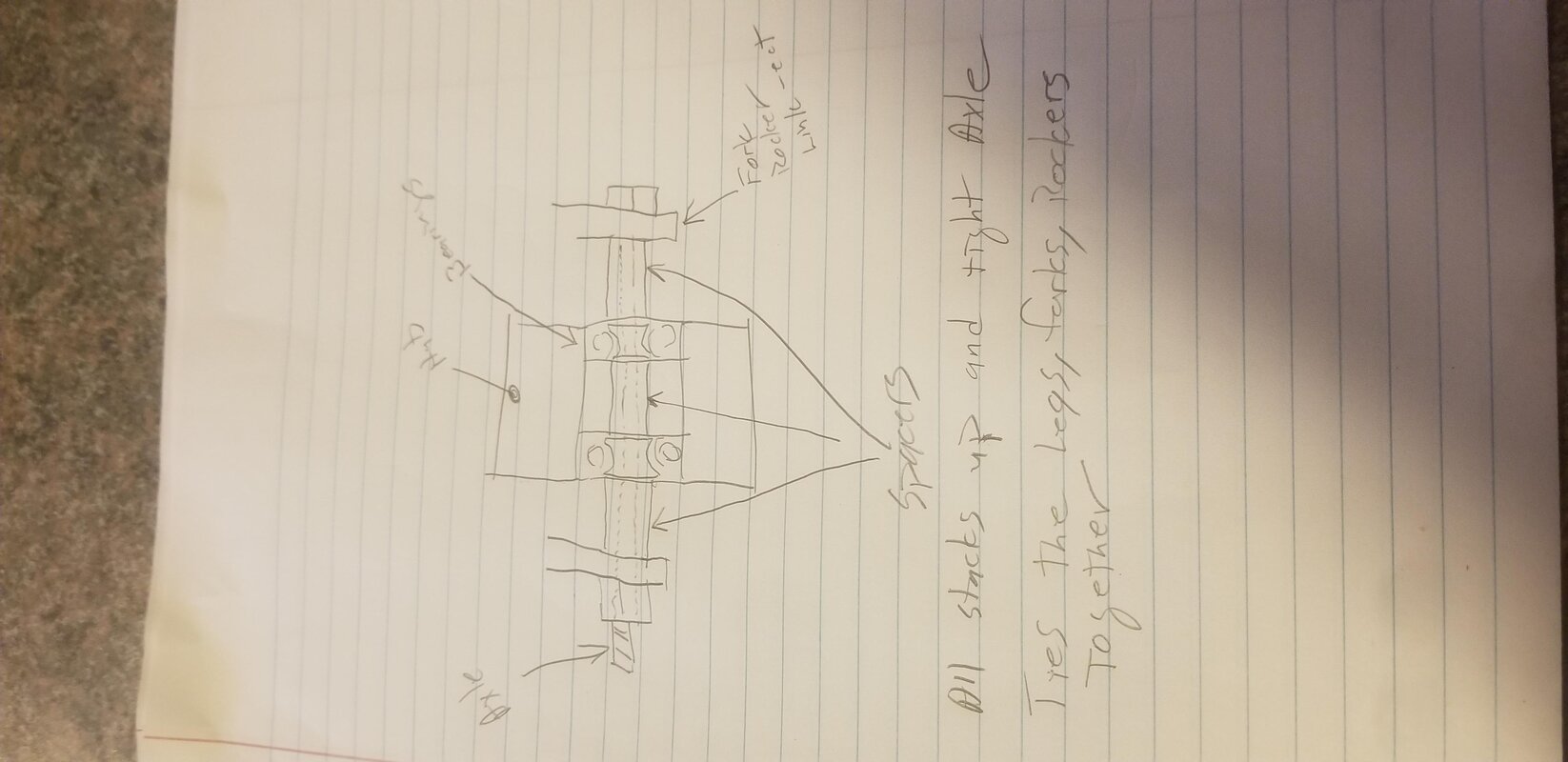

Do not pin or set screw the axle.

Axle must be solidly tight. You will get some weird flex and gyrating if loose.

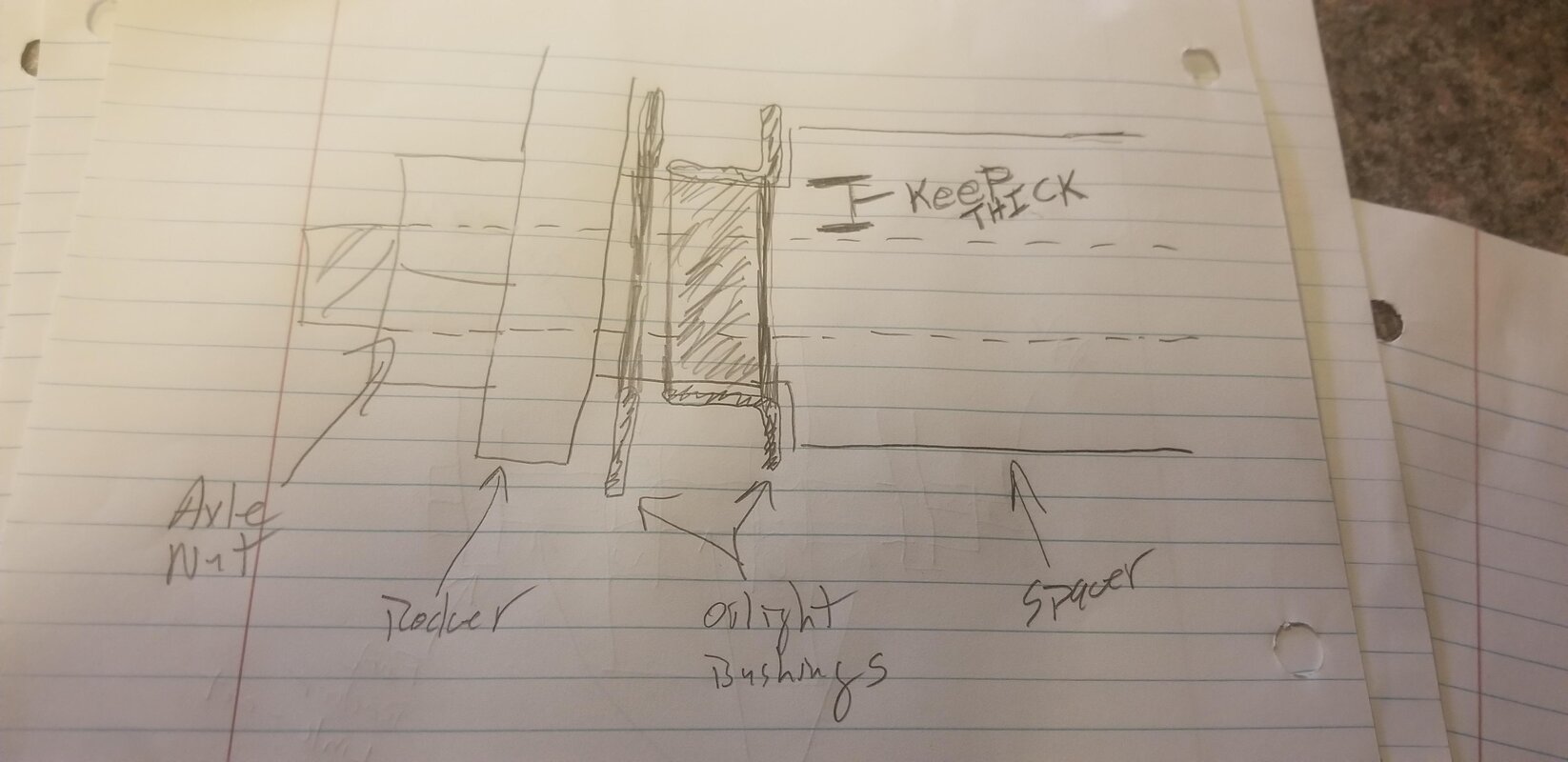

The best way I have found is turning a step on a spacer and press bushing into stay method.

In mine I was able to up-size the seal and that gave me the meat (metal thickness) to work with.

Axle must be solidly tight. You will get some weird flex and gyrating if loose.

The best way I have found is turning a step on a spacer and press bushing into stay method.

In mine I was able to up-size the seal and that gave me the meat (metal thickness) to work with.