Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

88 Blazer Trike

- Thread starter Fowler

- Start date

- Moderator

- #724

I also ordered a finger switch because my feet do not move well and a sleeve to go over it and the hose

View attachment 130058

Hahaha! Of course the obligatory feet shot. At least you covered up the toenails with the Crocs...

LarryA

500+ Posts

I think the finger switch will be good once you get used to it...done some crazy contortions with a foot pedal tig welding while laying under a vehicle.

Fowler

◇BUILD IT BOB◇

- Thread starter

- #726

Got my switch in but the plug is not right. So I returned it.

I can still TIG weld by using the scratch start method. That's OK on flat clean surface but I had a hell of a time trying to weld the chain. I could use my wire welder but it takes so much cleaning after welding. The switch from Lincoln is more expensive then I can do right now. I spent a lot on Xmas and my son's birthday.

I bought him a new pistol

As I stated before my normal use TIG welder (YES WELDER) died. I worked with the manufacture and we determined it was out of warranty and would cost to much to fix. I thought that was the end of that so I purchased the TIG torch for my Lincoln. After a few days YesWelder contacted me back and offered me a refurbished TIG welder for free. I was not expecting that. I will give the chain a try again when it comes in. Still not sure I will be able to get it to weld the way I like. I am still not the best at my TIG welding yet. Need a lot more practice.

I can still TIG weld by using the scratch start method. That's OK on flat clean surface but I had a hell of a time trying to weld the chain. I could use my wire welder but it takes so much cleaning after welding. The switch from Lincoln is more expensive then I can do right now. I spent a lot on Xmas and my son's birthday.

I bought him a new pistol

As I stated before my normal use TIG welder (YES WELDER) died. I worked with the manufacture and we determined it was out of warranty and would cost to much to fix. I thought that was the end of that so I purchased the TIG torch for my Lincoln. After a few days YesWelder contacted me back and offered me a refurbished TIG welder for free. I was not expecting that. I will give the chain a try again when it comes in. Still not sure I will be able to get it to weld the way I like. I am still not the best at my TIG welding yet. Need a lot more practice.

Fowler

◇BUILD IT BOB◇

- Thread starter

- #727

I need to switch my efforts to my other trike for a few. I need to build a new front end for it. I hope it will only take a couple weeks

VW coilovers for Leading Link forks

VW coilovers for Leading Link forks

Fowler

◇BUILD IT BOB◇

- Thread starter

- #728

Well it took longer than I thought to refresh my other trike. I'm done what I am going to do to it for now. I may add a front brake system but I'm still researching that.

View: https://drive.google.com/file/d/1dZhnFBe1ppMVJdX0AaxX6I5Tq1-GIZtW/view?usp=drive_link

So I am back to working on this trike.

First thing is I have to replace the neck bolt I stole from this trike for the other trike.

I have it on order and will start on this trike again once its here.

View: https://drive.google.com/file/d/1dZhnFBe1ppMVJdX0AaxX6I5Tq1-GIZtW/view?usp=drive_link

So I am back to working on this trike.

First thing is I have to replace the neck bolt I stole from this trike for the other trike.

I have it on order and will start on this trike again once its here.

Fowler

◇BUILD IT BOB◇

- Thread starter

- #729

I got the neck bolt in and then could not find the bearings. I have ordered the bearings.

Mounted the seats (these are just temporary seats / place holders)

Mounted some front hardware.

The Ol'Lady and I may go for a ride tomorrow or Monday.

when I start back on it I need to reinstall everything I removed.

Mounted the seats (these are just temporary seats / place holders)

Mounted some front hardware.

The Ol'Lady and I may go for a ride tomorrow or Monday.

when I start back on it I need to reinstall everything I removed.

Fowler

◇BUILD IT BOB◇

- Thread starter

- #730

I hate these damn braces I wear on my legs and feet. They get caught on everything.

Yesterday i decided to get the engine back in place. I have it on rollers so I pulled the engine around and jacked up the frame.

My braces caught on something and I tripped and landed on the frame.

The frame came down and on top of me. Almost changed me from a HE to a SHE!

No serious injuries to me or the frame. I just got busied up some and cant walk to well or bend my left leg to much.

I iced my leg last night and went in the jacuzzi this morning. It does feel a little better this morning. I still had to get the Ol'Lady to help me put my shoes and socks on though.

I was planning to go back out and work on it today anyway but the Ol'Lady got mad at me when I told her.

Not sure what I will do yet.

Yesterday i decided to get the engine back in place. I have it on rollers so I pulled the engine around and jacked up the frame.

My braces caught on something and I tripped and landed on the frame.

The frame came down and on top of me. Almost changed me from a HE to a SHE!

No serious injuries to me or the frame. I just got busied up some and cant walk to well or bend my left leg to much.

I iced my leg last night and went in the jacuzzi this morning. It does feel a little better this morning. I still had to get the Ol'Lady to help me put my shoes and socks on though.

I was planning to go back out and work on it today anyway but the Ol'Lady got mad at me when I told her.

Not sure what I will do yet.

irondad01

150+ Posts

Maybe take time to recover for a couple days, the trike has been waiting for you ,it can wait a little longer.

LarryA

500+ Posts

folks talk of the dangers of riding trikes and bikes, but there are a lot of cuts, bumps and burns building these contraptions too.. Bob is a testament to that.. Heal fast Bob!

Fowler

◇BUILD IT BOB◇

- Thread starter

- #733

Yep, Unfortunately I have had more than my share of them.folks talk of the dangers of riding trikes and bikes, but there are a lot of cuts, bumps and burns building these contraptions too.. Bob is a testament to that.. Heal fast Bob!

Decided to repair one of my 3D printers today instead. I still get burns from them but they are a lot smaller burns.

Pegasus1300

5250+ Posts

Bob did you start another thread on your Blazer trike build or did you get stalled on it. Very interesting idea.

Fowler

◇BUILD IT BOB◇

- Thread starter

- #735

No, this has just been a very long build. Life just gets in the way sometimes.Bob did you start another thread on your Blazer trike build or did you get stalled on it. Very interesting idea.

I did start a thread on my other Trike though

VW Coilovers for Leading Link Forks

Fowler

◇BUILD IT BOB◇

- Thread starter

- #742

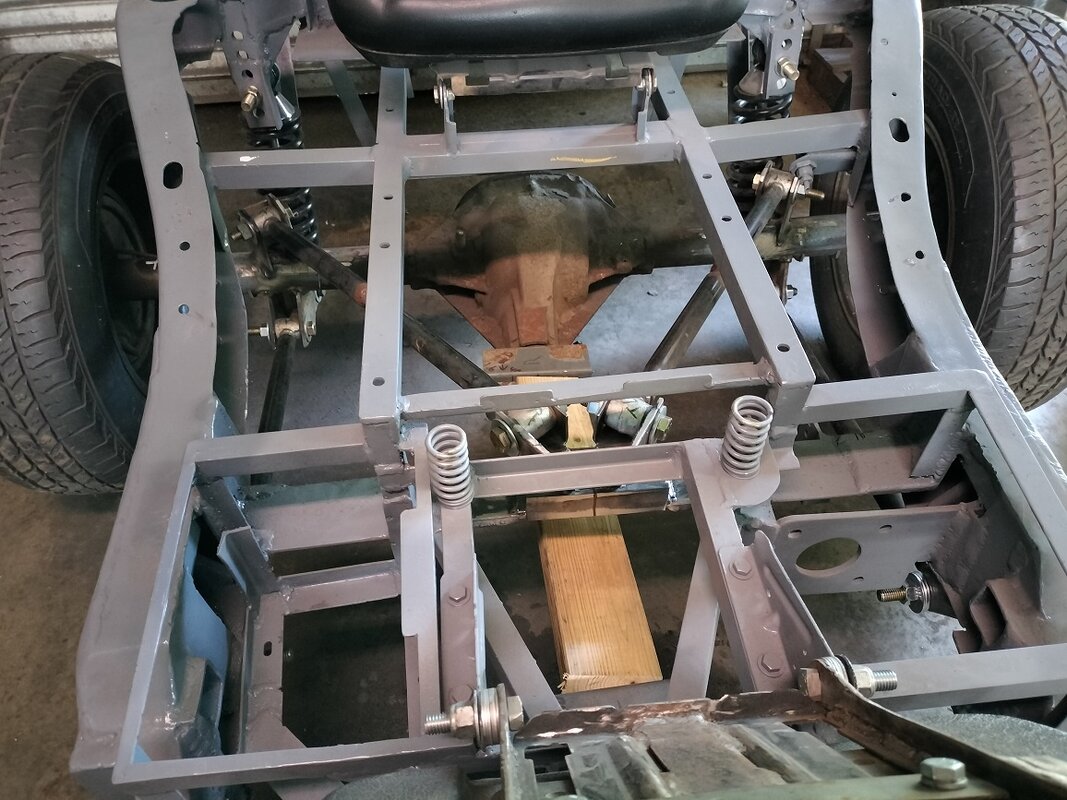

Worked on this for a while today after I mowed the grass.

Got the side to side right

Got the drive line geometry right

The measurement from a fixed point on either side of the rear to the neck bot and was 5/8 inch off

Shorten the left side lower link by 5/16 and put it back on.

Next time I will adjust it all again and see what I get.

Got the side to side right

Got the drive line geometry right

The measurement from a fixed point on either side of the rear to the neck bot and was 5/8 inch off

Shorten the left side lower link by 5/16 and put it back on.

Next time I will adjust it all again and see what I get.

Fowler

◇BUILD IT BOB◇

- Thread starter

- #743

All adjusted again.

The measurement from each side of the axle to the neck bolt is 1/8" off. The left side is 1/8" longer.

In order to correct that I would need to shorten the left link bar side by 1/16"

I'm not going to worry about it. I don't think that small amount will matter.

Next time I will check all the measurements again, adjust if needed then tack weld the upper brackets and mount the upper link bars.

The measurement from each side of the axle to the neck bolt is 1/8" off. The left side is 1/8" longer.

In order to correct that I would need to shorten the left link bar side by 1/16"

I'm not going to worry about it. I don't think that small amount will matter.

Next time I will check all the measurements again, adjust if needed then tack weld the upper brackets and mount the upper link bars.

Fowler

◇BUILD IT BOB◇

- Thread starter

- #745

I have been busy working around the house so have not had a chance to get back to working on the Trike

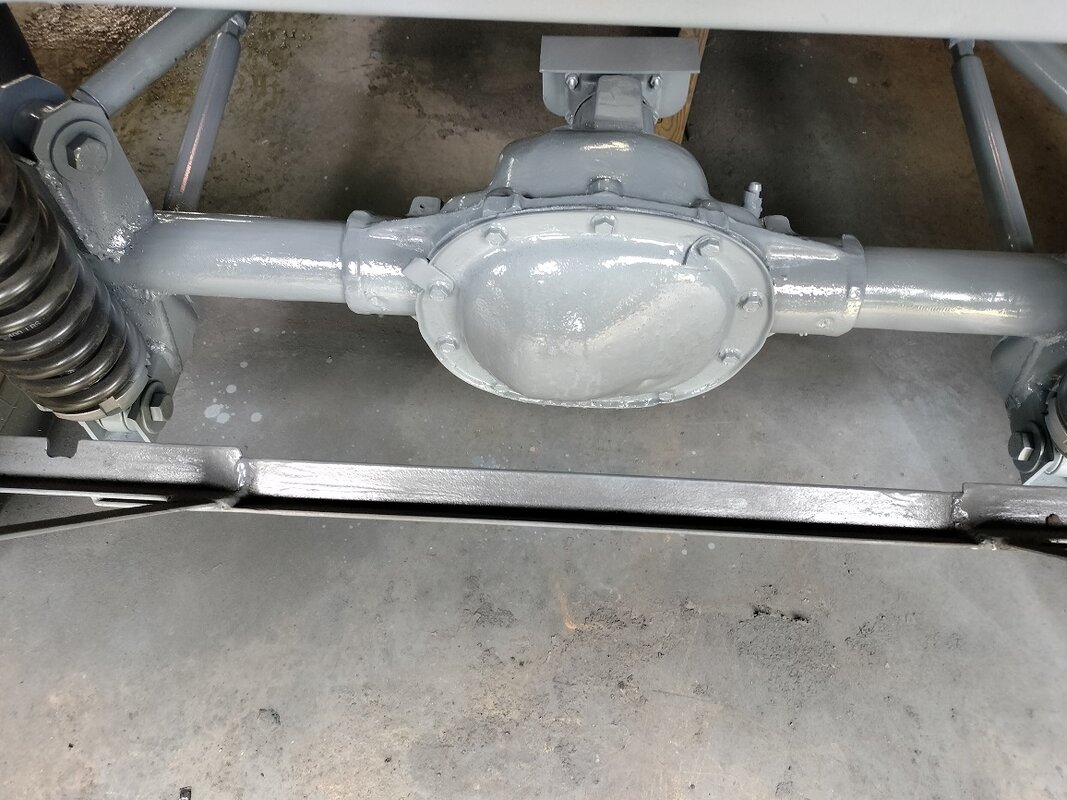

I think my next steps will be to clean up the axle and paint.

Then I think I will go back to the steering again.

But today I have to work on a 2009 Chevy HHR. No electrical power at all. Even with a new battery. I have checked every fuse I can find with no luck. It's been a good car and has close to 300K so if I cant get it fixed today I'm getting rid of it. I will donate it.

Hopefully Friday I will be back to working on the trike. The next couple days I have VA appointments. VA has been trying to talk me into a few different surgeries. I don't want to do it and I keep telling them not yet.

I think my next steps will be to clean up the axle and paint.

Then I think I will go back to the steering again.

But today I have to work on a 2009 Chevy HHR. No electrical power at all. Even with a new battery. I have checked every fuse I can find with no luck. It's been a good car and has close to 300K so if I cant get it fixed today I'm getting rid of it. I will donate it.

Hopefully Friday I will be back to working on the trike. The next couple days I have VA appointments. VA has been trying to talk me into a few different surgeries. I don't want to do it and I keep telling them not yet.

Fowler

◇BUILD IT BOB◇

- Thread starter

- #747

I started putting the steering back together but the forks are stiff. Then I remembered, I forgot a bearing spacer and was going to fix it later. Well its later so that is next.

I have to wait until I can get both my son and my Ol'Lady to help me.

I will jack the trike up to a certain point then my son and I will lift the forks off while my Ol'Lady pulls the bolt out and puts it back in with all the spacers and bearings.

My Ol'Lady is not happy about doing this!

I have to wait until I can get both my son and my Ol'Lady to help me.

I will jack the trike up to a certain point then my son and I will lift the forks off while my Ol'Lady pulls the bolt out and puts it back in with all the spacers and bearings.

My Ol'Lady is not happy about doing this!

Fowler

◇BUILD IT BOB◇

- Thread starter

- #748

I have the front end ready to pull, just waiting on the Ol'Lady.

While I am waiting I made a cross brace at the very front

I still need to trim the front of the frame

I was going to weld it on but it makes it easier without it when pulling the engine.

So I bolted it on with 4 3/8" grade 8 bolts

I put angle steel on the sides as you can see and also on the bottom (you can't see it in the picture)

This pipe was longer and I was putting it under the frame as a jack point. So I made this to make it easier.

While I am waiting I made a cross brace at the very front

I still need to trim the front of the frame

I was going to weld it on but it makes it easier without it when pulling the engine.

So I bolted it on with 4 3/8" grade 8 bolts

I put angle steel on the sides as you can see and also on the bottom (you can't see it in the picture)

This pipe was longer and I was putting it under the frame as a jack point. So I made this to make it easier.

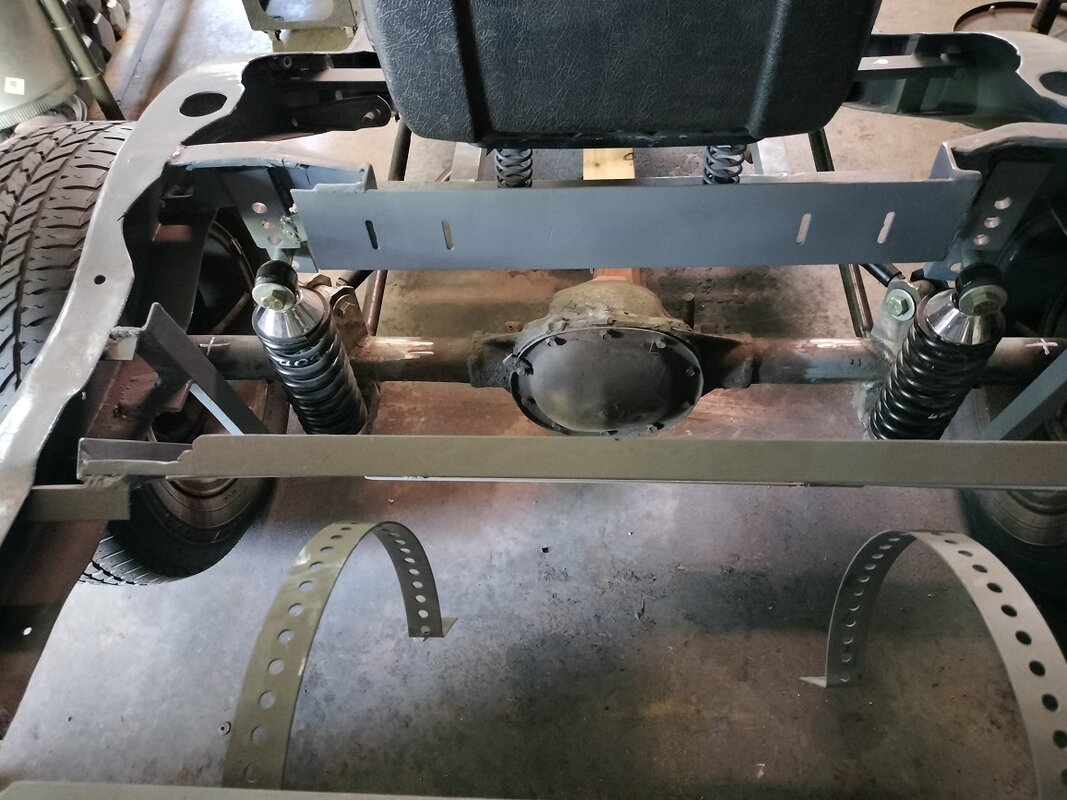

While you are at the rear end, make damn sure you check the fluid level, and grease the bearings??? just saying...I was cleaning up the rear and found some identifying marks

have not looked them up yet

View attachment 133875View attachment 133876

View attachment 133877

Cleaned up and painted

View attachment 133878

View attachment 133879

Fowler

◇BUILD IT BOB◇

- Thread starter

- #750

Thanks,While you are at the rear end, make damn sure you check the fluid level, and grease the bearings??? just saying...

I plan to pull it apart anyway.

Still have not gotten the front done yet. Still waiting on the Ol'Lady. She says she will help when we get back from the beach. If not I will get my neighbor to help.

Similar threads

- Sticky

- Replies

- 1

- Views

- 609

- Replies

- 3

- Views

- 5,668