Have done some reading about my noisy rear brakes and found that Lyndall rear brake pads can do the trick. My problem now is I cannot find the exact fitting pads for my "09" Tri-Glide. Does anyone who have replaced their rears have the part numbers?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lyndall Brake Pads

- Thread starter Offroadmaniac

- Start date

Have done some reading about my noisy rear brakes and found that Lyndall rear brake pads can do the trick. My problem now is I cannot find the exact fitting pads for my "09" Tri-Glide. Does anyone who have replaced their rears have the part numbers?

When I had my 10 tri I installed the Lyndall raceing pads and they made a world of difference -- sorry can't remember the part # but if you get on JP Cycles, or Dennis Kirk or even the Lyndall web site they will have the part # you need -- good luck

A few weeks ago I was looking for the Lyndall pads for the rear brakes on my 2014 TriGlide. Went to J&P website and found some confusing numbers, so I called them. The man said they had them for the front but not the rear. I went to the Lyndall website WWW.lyndallbrakes.com and did not find the Triglide, so I ended up calling them at (800) 400-9490. Jill at Lyndall said that they did indeed have a few sets left, and that they were actually considering discontinuing production on the TriGlide pads! I got the set of part# 7255 ($89.00); these are for 09-14 TriGlide rear, four pads and complete set of replacement bolts. Happy guy!

The Lyndall Pads come with bolts now?? I use to get my pads from Dennis Kirk,Eastern performance.

Ebay has them too..

Pads are 7254 for the gold Plus for the fronts.. 7255 gold plus rear. Surprised to hear they were $89.00 they usually go for over $100.00 for the rears alone.

Have to check my extra sets I have laying around I do not believe any bolts were included.

Ebay has them too..

Pads are 7254 for the gold Plus for the fronts.. 7255 gold plus rear. Surprised to hear they were $89.00 they usually go for over $100.00 for the rears alone.

Have to check my extra sets I have laying around I do not believe any bolts were included.

The Lyndall Pads come with bolts now??

Have to check my extra sets I have laying around I do not believe any bolts were included.

My EBC's came with bolts...

My EBC's came with bolts...

EBC yes..Lyndall usually no..Unless something changed..

- Thread starter

- #7

A few weeks ago I was looking for the Lyndall pads for the rear brakes on my 2014 TriGlide. Went to J&P website and found some confusing numbers, so I called them. The man said they had them for the front but not the rear. I went to the Lyndall website WWW.lyndallbrakes.com and did not find the Triglide, so I ended up calling them at (800) 400-9490. Jill at Lyndall said that they did indeed have a few sets left, and that they were actually considering discontinuing production on the TriGlide pads! I got the set of part# 7255 ($89.00); these are for 09-14 TriGlide rear, four pads and complete set of replacement bolts. Happy guy!

Thanks for the part number, exactly what I needed. I could not find anything on J&P or Lyndall's website either. I searched the part number you gave me and it says that they are $102.81 a pair on Amazon and to order two pair for two discs and on Revzilla they have a set of four pads for $80.95. This is still kind of confusing but I am grabbing the ones on Revzilla.

Is the part number the same for the newer Harley's?? 14-15 years

I know it is for the '14 TG; that is what I bought them for. I have to think that it would be for the '15 as well.

As a side note, when I talked to Jill at Lyndall, she said that they really prefer to sell direct... said that way you could be sure that what you are getting are authentic Lyndall parts and not knock-offs. I guess there have been a few issues...:Shrug:

As a side note, when I talked to Jill at Lyndall, she said that they really prefer to sell direct... said that way you could be sure that what you are getting are authentic Lyndall parts and not knock-offs. I guess there have been a few issues...:Shrug:

I am surprised since the newer model years that have larger rotors they are still using the same brake pads back to the 09 MY..:xzqxz:

I know Lyndall has dealers they sell there products to also .

I know Lyndall has dealers they sell there products to also .

Used Lyndall pads on my '09 and wife's '11 when the OEMs were wearing out. Really felt the difference. Hope they don't discontinue, planned on using them on her '14 and my 'Free. Used them on my Ultra, Dyna, and Softail.

OK, sat down this morning to install the Lyndall 7255 pads, and they are different than the OEM HD pads. No lit included that says anything about this...

Anyone else seen this?

What do you mean by different?

OK, long story short... I just looked at the HD website (guess I should have done this first). The pads I got from Lyndall look just like the ones listed for the '09-'13 TriGlide, HD part# 83911-09B, while the ones for the '14, HD part# 41300033, look completely different.

I guess I will have to contact Lyndall on Monday and get these exchanged. Hope they have the correct ones, or I will be looking to EBC!

I guess I will have to contact Lyndall on Monday and get these exchanged. Hope they have the correct ones, or I will be looking to EBC!

OK, long story short... I just looked at the HD website (guess I should have done this first). The pads I got from Lyndall look just like the ones listed for the '09-'13 TriGlide, HD part# 83911-09B, while the ones for the '14, HD part# 41300033, look completely different.

I guess I will have to contact Lyndall on Monday and get these exchanged. Hope they have the correct ones, or I will be looking to EBC!

You are correct, you have the pads for the 09 - 13 Triglide, 14 and later are a different pad.

- Moderator

- #19

a picture is worth a thousand words. Quite a difference.

- Thread starter

- #20

Got my new Lyndall pads in the mail. Do you need any special tool to replace them? also can you get the tire out from under the fender when you jack up the axle or is there a certain way to remove them?

Got my new Lyndall pads in the mail. Do you need any special tool to replace them? also can you get the tire out from under the fender when you jack up the axle or is there a certain way to remove them?

Make sure the rear axle is hanging down as low as possible to get the tires on and off..maybe even pump up the shocks to push down on the axle to help. They can be a bit of a pain at times..:xzqxz:

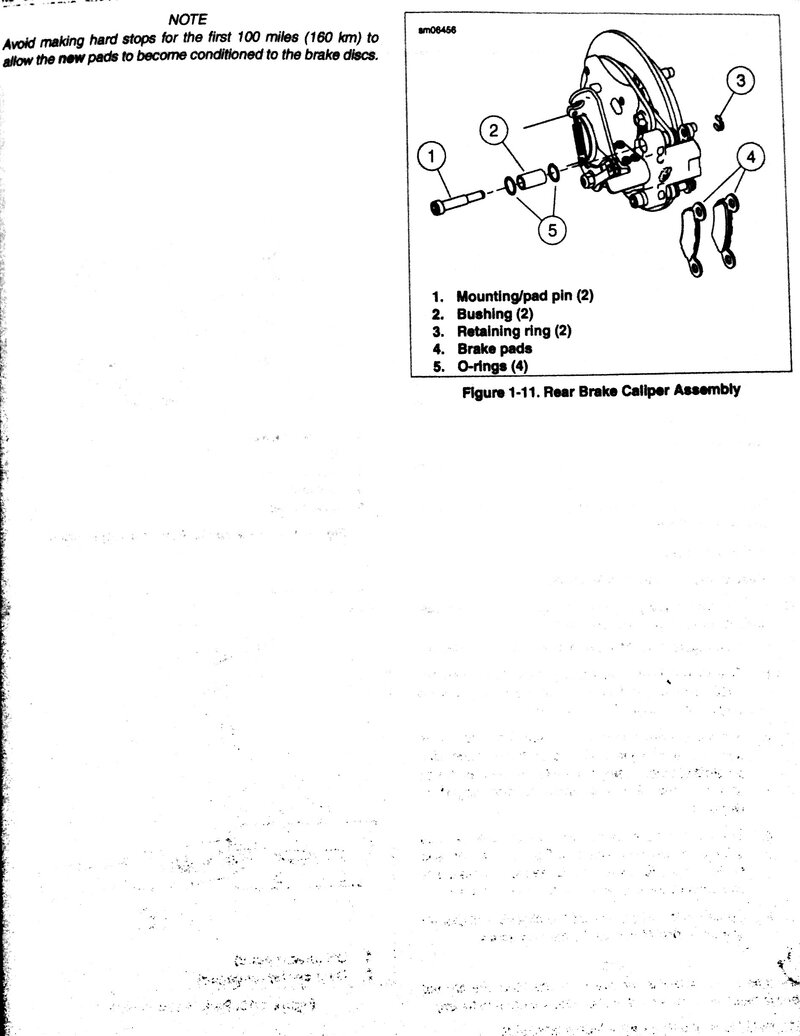

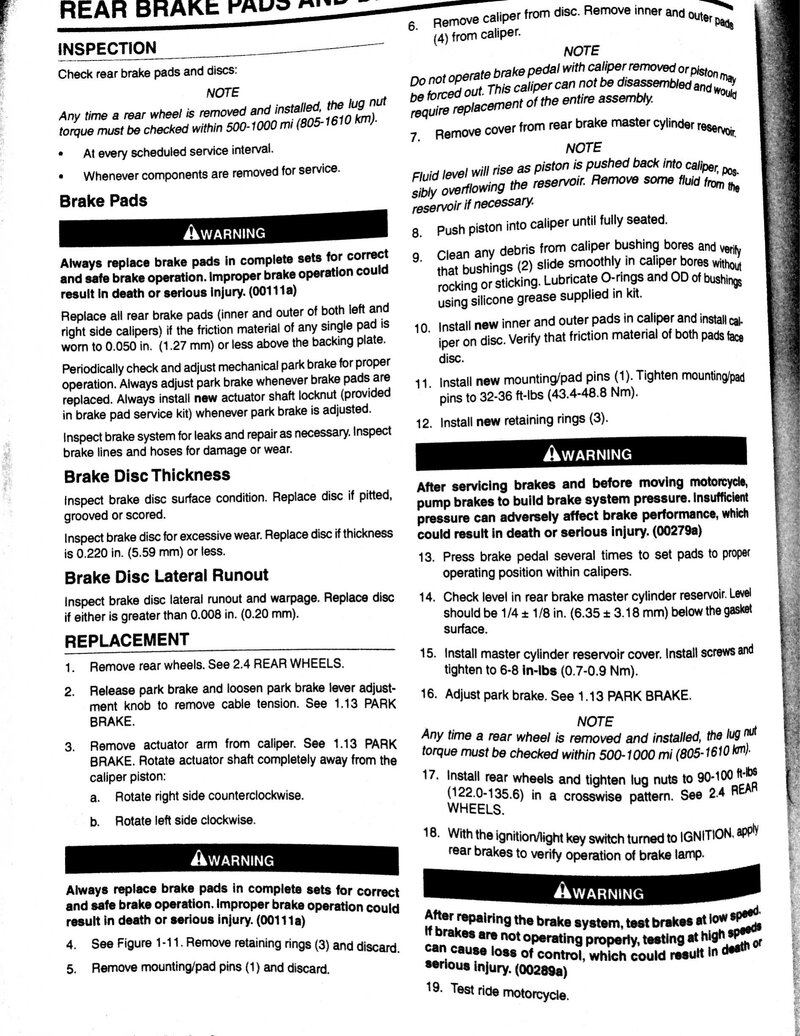

No special tools for brakes wrench,screwdriver,check slider bushings,push back caliper pistons.

Got my new Lyndall pads in the mail. Do you need any special tool to replace them? also can you get the tire out from under the fender when you jack up the axle or is there a certain way to remove them?

Nope, as I recall, Allen wrenches were as special as it got. It was a little awkward getting the top caliper bolts broke loose. I was only able to get the long end of the Allen in there then used an open end wrench to turn the Allen. If you had the Allen sockets, the longer ones preferably with the ball ends, these might work well. I've found a set of those handy in many other areas so might be worth picking up sometime, but not required for this job.

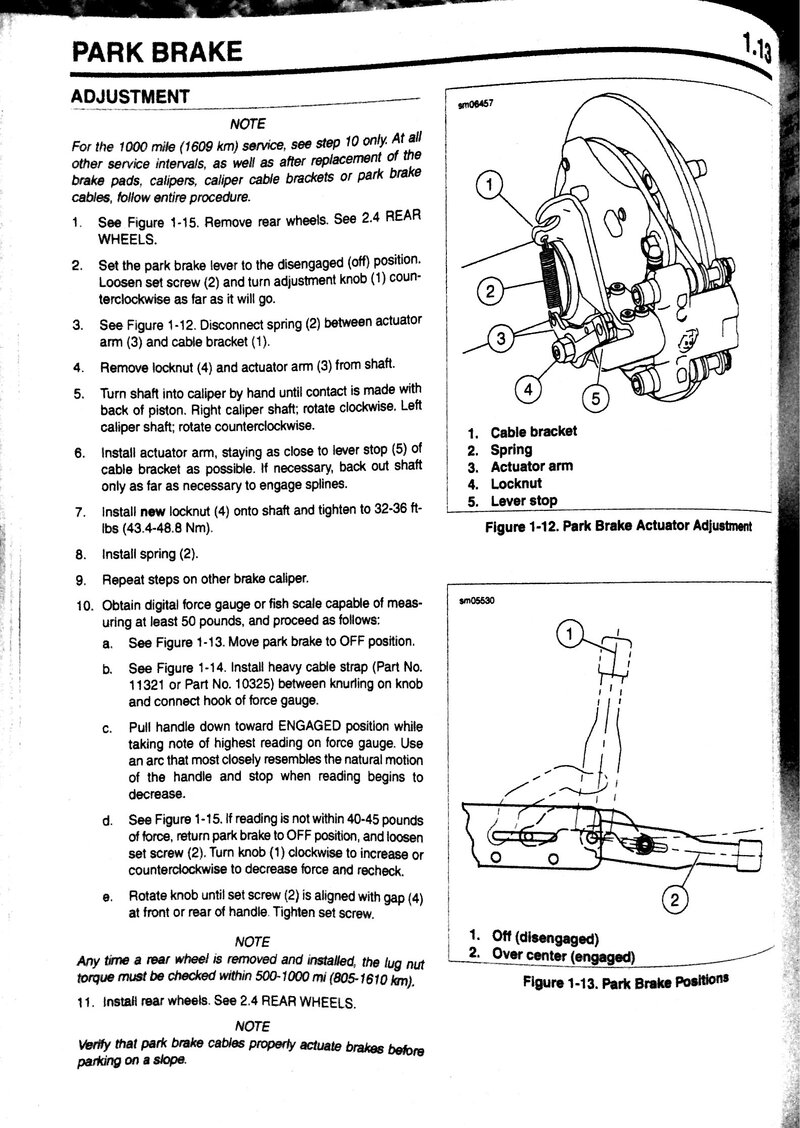

Do you have the service manual and trike supplement? It's pretty straight forward in there. If not, we should get the requisite pages for you. You need to disconnect the parking brake and back off the adjusting bolt behind the caliper piston in order to press the piston back in. Not like most cars where you can just c clamp the piston back a little. I went this route myself before reading the manual-I'm a bit ashamed to say. Sometimes I get ahead of myself and assume based on past experience. Better to read the whole section first and get it in your head then re-read as you go/as needed in my opinion.

As far as getting the tires off, yes you have to get it up a ways to clear the fenders. You can start to rotate the tire up, back, and then start turning it towards the center (high point) of the fender. You can get away with a little less height that way versus trying to keep the tire in the same position as it comes out if that makes sense.

I guess I should have done a bit more research up front... I just figured the person at Lyndall that took my order knew what she was talking about when she asked me what year and I told her a '14 TG.:Shrug:

Final update (for a while at least) :gah: Lyndall has not started production on the pads for the '14 and '15 MY. and has no plans for them, probably for this season (?) They are sending me a shipping tag, and said will give me a full refund.:clapping:

NOW... since I still need new rear pads, can anyone tell me if they have found EBC (or other equal) rear pads for the '14s? All my searches for them also return '09-'13 pads. Really don't want to go back to the OEM HD pads, especially since I saw all the voids in the friction material on mine.

Thanks in advance!

- Thread starter

- #24

Make sure the rear axle is hanging down as low as possible to get the tires on and off..maybe even pump up the shocks to push down on the axle to help. They can be a bit of a pain at times..:xzqxz:

No special tools for brakes wrench,screwdriver,check slider bushings,push back caliper pistons.

Nope, as I recall, Allen wrenches were as special as it got. It was a little awkward getting the top caliper bolts broke loose. I was only able to get the long end of the Allen in there then used an open end wrench to turn the Allen. If you had the Allen sockets, the longer ones preferably with the ball ends, these might work well. I've found a set of those handy in many other areas so might be worth picking up sometime, but not required for this job.

Do you have the service manual and trike supplement? It's pretty straight forward in there. If not, we should get the requisite pages for you. You need to disconnect the parking brake and back off the adjusting bolt behind the caliper piston in order to press the piston back in. Not like most cars where you can just c clamp the piston back a little. I went this route myself before reading the manual-I'm a bit ashamed to say. Sometimes I get ahead of myself and assume based on past experience. Better to read the whole section first and get it in your head then re-read as you go/as needed in my opinion.

As far as getting the tires off, yes you have to get it up a ways to clear the fenders. You can start to rotate the tire up, back, and then start turning it towards the center (high point) of the fender. You can get away with a little less height that way versus trying to keep the tire in the same position as it comes out if that makes sense.

Thanks for the input, I would have tried the old c-clamp bit also. Any idea how I can get those pages from the service manual?

Thanks for the input, I would have tried the old c-clamp bit also. Any idea how I can get those pages from the service manual?

I could probably get some info for you tomorrow night.. I'm out of town and away from the shop at the moment. I should be back by tomorrow night. If someone else doesn't get them to you first, I will try to post the pertinent information.

- - - Updated - - -

Thanks for the input, I would have tried the old c-clamp bit also.

Once you back off the bolts behind the pistons, I was able to push them back in enough with my thumbs.. no c clamp needed in my case.

Also, I remember the manual said to replace the caliper bolts and the retaining clips. I reused them, but they were showing some wear and I will probably replace them next time. This was at about 13,000 miles. I don't know where you're at mileage-wise.

I wasn't able to find them sold separately, Harley sold them as a kit with new pads. They may have a separate part number though.. The kit number was 83911-09B. $80-$90 including the pads which you don't need if you're going lyndall.

I wasn't able to find them sold separately, Harley sold them as a kit with new pads. They may have a separate part number though.. The kit number was 83911-09B. $80-$90 including the pads which you don't need if you're going lyndall.

Also, I remember the manual said to replace the caliper bolts and the retaining clips. I reused them, but they were showing some wear and I will probably replace them next time. This was at about 13,000 miles. I don't know where you're at mileage-wise.

I wasn't able to find them sold separately, Harley sold them as a kit with new pads. They may have a separate part number though.. The kit number was 83911-09B. $80-$90 including the pads which you don't need if you're going lyndall.

They're available separately, PN 83907-09 for the pin and PN 83908-09 for the clip.

Just a heads up , If you're going to replace the front pads you'll need spline sockets to remove the caliper bolts..

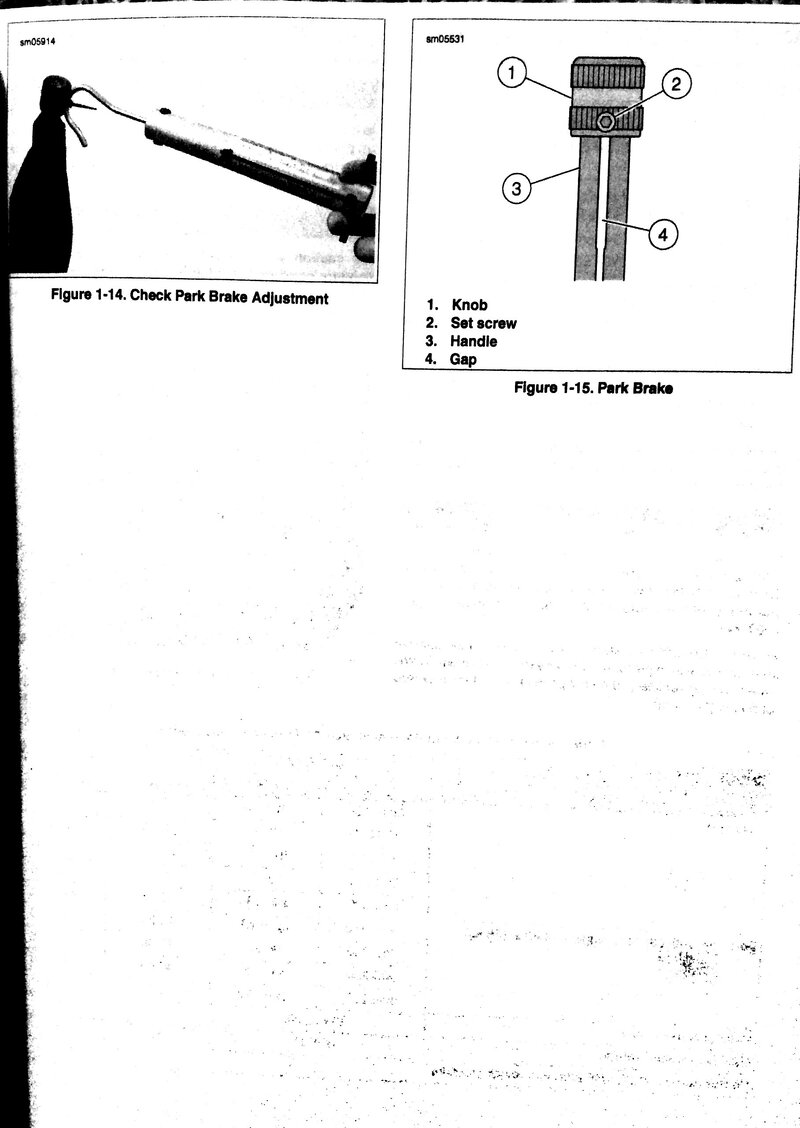

Here are some pictures with the steps to do the job. Let me know if you are unable to blow them up and read them.

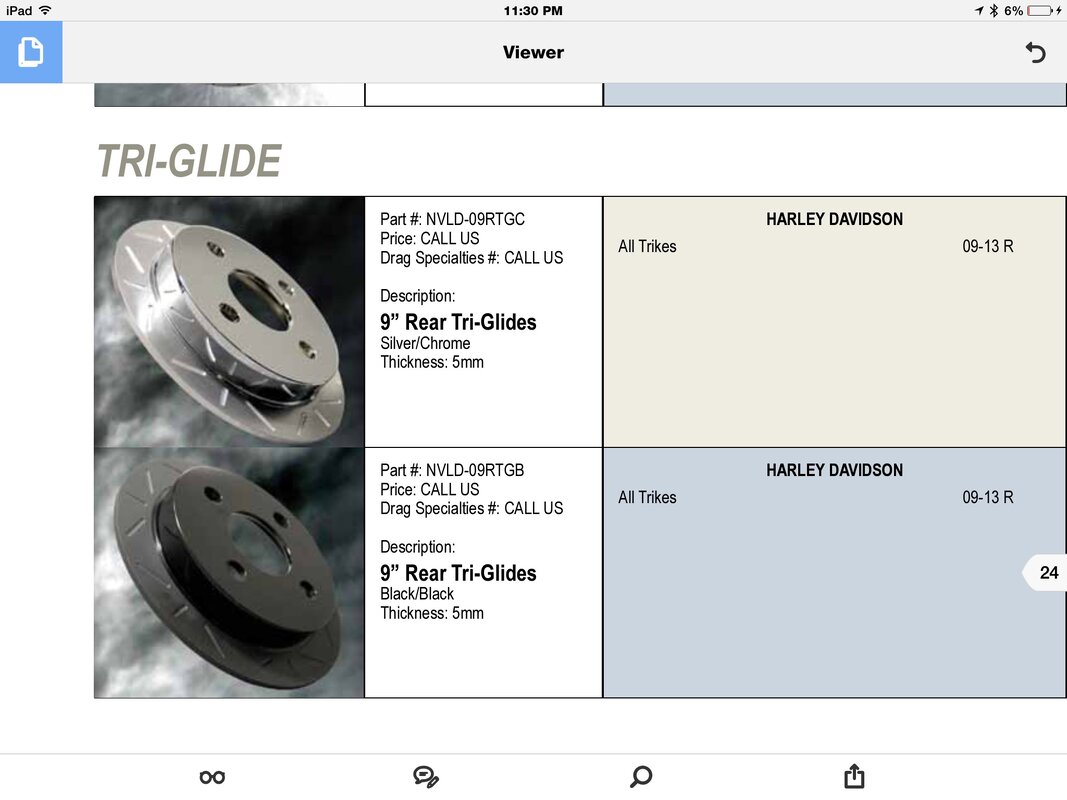

When I did my dad's, his discs were scarred enough that I wanted to have them turned. They can't turn these on a regular brake disc machine because these are steel. I ended up going to a guy who had a machine for turning flywheels which worked out. Just had him take enough to clean them up. I think .022 is the minimum tolerance and they don't start out much thicker than that. Also Lyndall makes a rotor for these trikes too, if you wanted to replace them. I attached the page from their catalog at the bottom.

When I did my dad's, his discs were scarred enough that I wanted to have them turned. They can't turn these on a regular brake disc machine because these are steel. I ended up going to a guy who had a machine for turning flywheels which worked out. Just had him take enough to clean them up. I think .022 is the minimum tolerance and they don't start out much thicker than that. Also Lyndall makes a rotor for these trikes too, if you wanted to replace them. I attached the page from their catalog at the bottom.

Attachments

- Thread starter

- #30

Here are some pictures with the steps to do the job. Let me know if you are unable to blow them up and read them.

When I did my dad's, his discs were scarred enough that I wanted to have them turned. They can't turn these on a regular brake disc machine because these are steel. I ended up going to a guy who had a machine for turning flywheels which worked out. Just had him take enough to clean them up. I think .022 is the minimum tolerance and they don't start out much thicker than that. Also Lyndall makes a rotor for these trikes too, if you wanted to replace them. I attached the page from their catalog at the bottom.

Thank you very much, they printed great.