Fearless

Gone But Not Forgotten

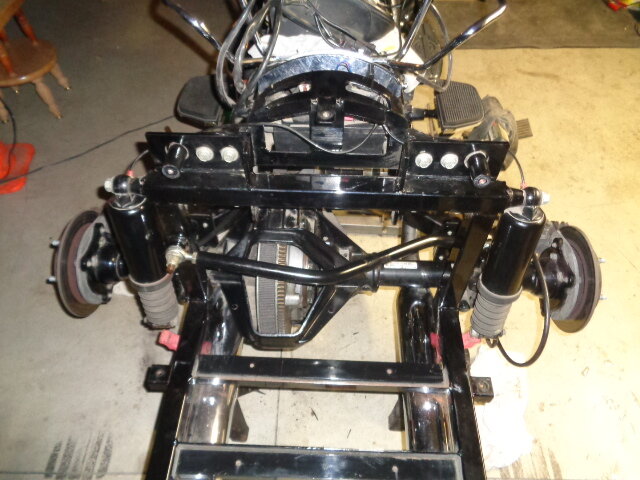

I mean the front pulley change was one great improvement for power and using 6th gear at all. But I was under Old Shiney this afternoon, and the drive pulley is riding the Differential side of the rear pulley. It is really tight and wearing the side of the belt. Either something has shifted or the re-adjustment of the belt after pulley change didn't get checked as it should have. I plan on removing the body and do a complete realignment/adjustment of the rear axle making sure nothing is loose or out of place. I am going to stop by the Harley shop and ask a few questions before I open the tool cabinets. I may even purchase a belt tensioner gage. I will be stopping at Lowes Hardware and pickup two magnetic Lasers to assist in the alignment. I plan on doing step by step pictures, I have a 09' Triglide supplement to assist in the project. this should prove to be interesting to say the least, and of course I will be compelled to clean everything that has been covered for 10 years yeppie. :Shrug:Wrench safely Fred

P.S. Did I ever tell ya I would much rather ride then wrench just sayin...:gah:

P.S. Did I ever tell ya I would much rather ride then wrench just sayin...:gah: