Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Floor jack cross beam to lift rear of Tri-Glide

- Thread starter stratmarshall

- Start date

I’ve used a cut 2x4 and floor Jack for many years , along with tire ramps .

Olddog

150+ Posts

I’ve used a cut 2x4 and floor Jack for many years , along with tire ramps .

How about a photo? That seems like a great, cheap solution.

How about a photo? That seems like a great, cheap solution.

Don’t have photos , but between the mufflers is a cross brace . Lift there with the 2x4 on lift. If not centered it will teeter …

Notgrownup

650+ Posts

I use the 2x4 between the mufflers and then Jack stands

- Thread starter

- #6

I found a video of someone using the crossbeam and lifting the trike/

He comes in from the primary side at a angle and lifts it. I wonder if you can rig something and come in from the rear and lift the entire trike? Id like to bring both sides up at the same time level.

"I’ve used a cut 2x4 and floor Jack for many years , along with tire ramps"

I'd like to see a couple of pixs of that myself.

He comes in from the primary side at a angle and lifts it. I wonder if you can rig something and come in from the rear and lift the entire trike? Id like to bring both sides up at the same time level.

"I’ve used a cut 2x4 and floor Jack for many years , along with tire ramps"

I'd like to see a couple of pixs of that myself.

DK Custom Products

Sponsor

You can see a couple of different ways to lift the rear of the trike in the video below.

I like to lift it from the rear, with a jack, then put jack stands under each side for maximum stability/safety. All this is shown in the video.

Kevin

I like to lift it from the rear, with a jack, then put jack stands under each side for maximum stability/safety. All this is shown in the video.

Kevin

SmittysTrike

100+ Posts

I just got one of those for just lifting the trike. Wont fit under the trike at all! Maybe it will if the lift kit was installed but as it sits from the factory it wont. And I do have a new low profile jack. If you look at the way the guy on you tube has his jack you'll see he's using it after its on ramps which will work to get the ramps out.

Old Road Dog

650+ Posts

Most of the time- like for fluid changes I use 3 car ramps. Put anti skid tape on the front one fore and aft to keep it from skeeching out when I run up it. My HF yellow bike lift will raise the whole trike up! Problem is as the trike service manual says to position it under the derby cover engaging the frame- the rear end lifts up but the front wheel nose dives so I put a piece of 4 × 4 under the front wheel. If lifting the front the rear end will dive so a piece of 4×4 vertically with carpet under the bumper levels it out. Anyway in order to get the lift to clear the frame some 1×4 under each wheel works well. I've also used a couple of 1 ton bottle jacks and pieces of 2x4 under the lifting points as shown in the video and you wont have a floor jack in way.

Trampas

1000+ Posts

I use a J & S trike jack, works for me and it is good for winter storage also, wheels off the ground

All for now Trampas

With the J & S jack lift it up and then lower slowly onto jack stands

All for now Trampas

With the J & S jack lift it up and then lower slowly onto jack stands

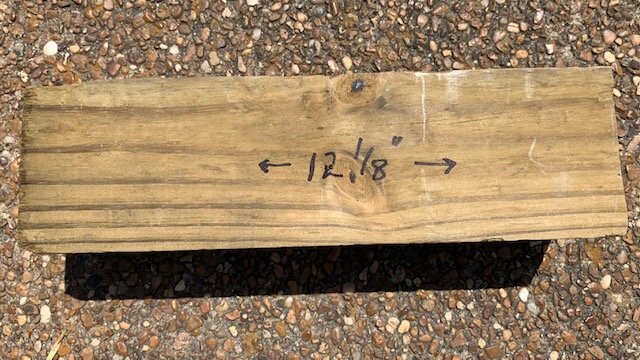

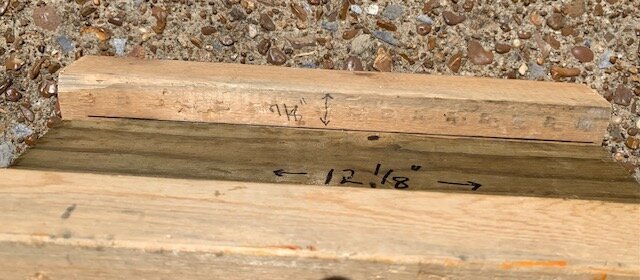

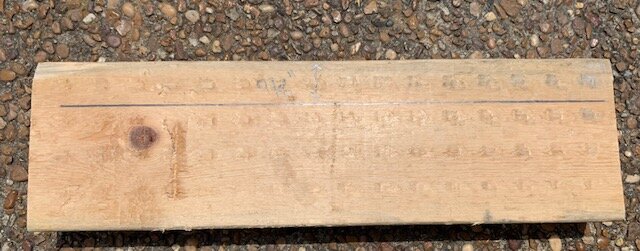

I made a lifting block a while back and while it worked ok I thought about some improvements. So yesterday I made a new one incorporating those improvements.

It is a 4x4 piece of wood I use to lift the rear of the trike by placing it under the rear frame crossmember. If you don't have any 4x4 lumber you can screw two pieces of 2x4 together. I cut it 12 1/8 inches long since this is the maximum width that will fit between the stock oem mufflers. I want it to fill the gap so I can mark the centerline and use that as a lifting point for the saddle on my floor jack. That way I can minimize the listing to either port or starboard as I jack the trike.

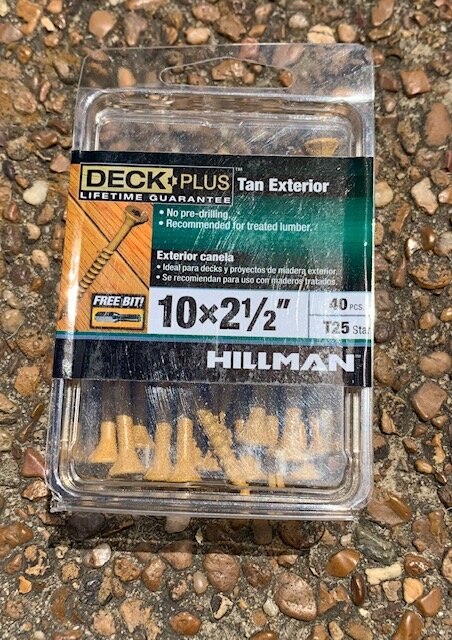

Now I don't want it to be able to slip off the crossmember so I added 2x4s on either side to create a channel for the crossmember to sit in. The 2x4s stand 7/8" proud over the lifting block. This is the maximum height so as not to contact the trike body before the lifting block contacts the crossmember. I secured the 2x4s with deck screws since I had these already on hand.

I've tried all different methods - 2x4 running between the crossmember rails, lifting blocks for the tie down loops which require two jacks or lots ov moving for one jack, etc. This seems to work the best of all I've tried. Hope it helps and appreciate any ideas to improve.

It is a 4x4 piece of wood I use to lift the rear of the trike by placing it under the rear frame crossmember. If you don't have any 4x4 lumber you can screw two pieces of 2x4 together. I cut it 12 1/8 inches long since this is the maximum width that will fit between the stock oem mufflers. I want it to fill the gap so I can mark the centerline and use that as a lifting point for the saddle on my floor jack. That way I can minimize the listing to either port or starboard as I jack the trike.

Now I don't want it to be able to slip off the crossmember so I added 2x4s on either side to create a channel for the crossmember to sit in. The 2x4s stand 7/8" proud over the lifting block. This is the maximum height so as not to contact the trike body before the lifting block contacts the crossmember. I secured the 2x4s with deck screws since I had these already on hand.

I've tried all different methods - 2x4 running between the crossmember rails, lifting blocks for the tie down loops which require two jacks or lots ov moving for one jack, etc. This seems to work the best of all I've tried. Hope it helps and appreciate any ideas to improve.

Attachments

arnie

450+ Posts

That looks really nice Jerry. I'll have to do a lil improvement on mine now. thanks

Olddog

150+ Posts

Anyone have a clear photo of the rear frame crossmember? I’m new to trikes and don’t want to screw anything up. Thanks, Al.

Jack Klarich

Gold Member

Anyone have a clear photo of the rear frame crossmember? I’m new to trikes and don’t want to screw anything up. Thanks, Al.

With the body removed you can see the cross members

- Thread starter

- #15

Kevin, thanks for the video in post #7. Did you just use 2 - 2x4's on top of the floor jack?

ultra fxr, thanks for the pixs. That looks like the easiest way to lift the rear of the trike.

I found a video of the the wood blocks used to lift the trike one wheel at a time. He shows it at 7:43 in the video then he shows how he made them.

The J$S trike jack would be perfect. I have one for my ultra it works great. To bad it can not convert it to work on the trike.

ultra fxr, thanks for the pixs. That looks like the easiest way to lift the rear of the trike.

I found a video of the the wood blocks used to lift the trike one wheel at a time. He shows it at 7:43 in the video then he shows how he made them.

The J$S trike jack would be perfect. I have one for my ultra it works great. To bad it can not convert it to work on the trike.

DK Custom Products

Sponsor

Kevin, thanks for the video in post #7. Did you just use 2 - 2x4's on top of the floor jack?

ultra fxr, thanks for the pixs. That looks like the easiest way to lift the rear of the trike.

I found a video of the the wood blocks used to lift the trike one wheel at a time. He shows it at 7:43 in the video then he shows how he made them.

The J$S trike jack would be perfect. I have one for my ultra it works great. To bad it can not convert it to work on the trike.

Yes, 2x4's is what we use between the jack and the crossmember.

Kevin

DK Custom Products

Sponsor

With the body removed you can see the cross members

Hey, I recognize that dirty TG. :laugh:

Kevin

Hey, I recognize that dirty TG. :laugh:

Kevin

The vape device on the passenger footboard is a dead giveaway!

DK Custom Products

Sponsor

The vape device on the passenger footboard is a dead giveaway!

haha, good eye. I did not see that at first. :laugh:

Kevin

I made a lifting block a while back and while it worked ok I thought about some improvements. So yesterday I made a new one incorporating those improvements.

It is a 4x4 piece of wood I use to lift the rear of the trike by placing it under the rear frame crossmember. If you don't have any 4x4 lumber you can screw two pieces of 2x4 together. I cut it 12 1/8 inches long since this is the maximum width that will fit between the stock oem mufflers. I want it to fill the gap so I can mark the centerline and use that as a lifting point for the saddle on my floor jack. That way I can minimize the listing to either port or starboard as I jack the trike.

Now I don't want it to be able to slip off the crossmember so I added 2x4s on either side to create a channel for the crossmember to sit in. The 2x4s stand 7/8" proud over the lifting block. This is the maximum height so as not to contact the trike body before the lifting block contacts the crossmember. I secured the 2x4s with deck screws since I had these already on hand.

I've tried all different methods - 2x4 running between the crossmember rails, lifting blocks for the tie down loops which require two jacks or lots ov moving for one jack, etc. This seems to work the best of all I've tried. Hope it helps and appreciate any ideas to improve.

Looking at Kevin's Trike pic - do you see any problem using the first cross member [nearest the bumper]? - the second in cross member is closer to the reinforced right angle braced frame, may be a better choice, as it closer to the load and reinforcement. Which are you using? Another thought, if you use the second cross member for jacking and the first member for the stabilizing jacks. [ would you have enough room to place the stabilizing jacks and then remove the floor jack?]

Ron

Jack Klarich

Gold Member

Looking at Kevin's Trike pic - do you see any problem using the first cross member [nearest the bumper]? - the second in cross member is closer to the reinforced right angle braced frame, may be a better choice, as it closer to the load and reinforcement. Which are you using? Another thought, if you use the second cross member for jacking and the first member for the stabilizing jacks. [ would you have enough room to place the stabilizing jacks and then remove the floor jack?]

Ron

Ron, my Freewheeler has the same frame as a Triglide

I have used the rear cross member to jack it up, I place jack stands under the lower shock mounts or under the swing arm depending on what service I may be doing

I hope this helps

Looking at Kevin's Trike pic - do you see any problem using the first cross member [nearest the bumper]? - the second in cross member is closer to the reinforced right angle braced frame, may be a better choice, as it closer to the load and reinforcement. Which are you using? Another thought, if you use the second cross member for jacking and the first member for the stabilizing jacks. [ would you have enough room to place the stabilizing jacks and then remove the floor jack?]

Ron

I've thought about that but don't really see any problem. I've jacked it several times this way with no problem.

DK Custom Products

Sponsor

Looking at Kevin's Trike pic - do you see any problem using the first cross member [nearest the bumper]? - the second in cross member is closer to the reinforced right angle braced frame, may be a better choice, as it closer to the load and reinforcement. Which are you using? Another thought, if you use the second cross member for jacking and the first member for the stabilizing jacks. [ would you have enough room to place the stabilizing jacks and then remove the floor jack?]

Ron

We've used both with no problems...been doing this for over a decade now...zero issues. AND, we do it a lot. Our last round of testing for the development of the NexGen Shocks had us jacking up the TG well over 100 times....probably closer to 300 times.

The front crossmember is closer to the frame right angle, and there is less leverage on the frame. The rear crossmember has a VERY HEAVY solid bar of steel sitting in the crossmember channel, giving it some serious extra rigidity. The whole frame is over engineered and strong...either one is fine.

Kevin

We've used both with no problems...been doing this for over a decade now...zero issues. AND, we do it a lot. Our last round of testing for the development of the NexGen Shocks had us jacking up the TG well over 100 times....probably closer to 300 times.

The front crossmember is closer to the frame right angle, and there is less leverage on the frame. The rear crossmember has a VERY HEAVY solid bar of steel sitting in the crossmember channel, giving it some serious extra rigidity. The whole frame is over engineered and strong...either one is fine.

Kevin

Thanks Kevin - your every day functional testing results, speak for themselves.

Ron

SmittysTrike

100+ Posts

I have a hitch on my trike so I came up with this. The bar sits about an eighth of an inch below the mounting brackets so I had to add the shims(?) Notice how the jack is off center. That keeps the load centered so it lifts level. It does teeter while up so if doing ANY work you have to use jack stands as soon as its where you want it.

I've been using the J&S trike lift since 2015

Hey Smitty I have that same jack/crossbeam setup. It doesn't quite clear the stock exhaust so I just drive the rear wheels on a 2x6 or 2x8 piece of scrap lumber, then it will clear.

I do like Ultra's crossmember idea though... probably gonna try that.

I do like Ultra's crossmember idea though... probably gonna try that.

I just got one of those for just lifting the trike. Wont fit under the trike at all! Maybe it will if the lift kit was installed but as it sits from the factory it wont. And I do have a new low profile jack. If you look at the way the guy on you tube has his jack you'll see he's using it after its on ramps which will work to get the ramps out.

SmittysTrike

100+ Posts

Hey Smitty I have that same jack/crossbeam setup. It doesn't quite clear the stock exhaust so I just drive the rear wheels on a 2x6 or 2x8 piece of scrap lumber, then it will clear.

Didn't think of doing that. Good idea!

Similar threads

- Replies

- 19

- Views

- 23,749