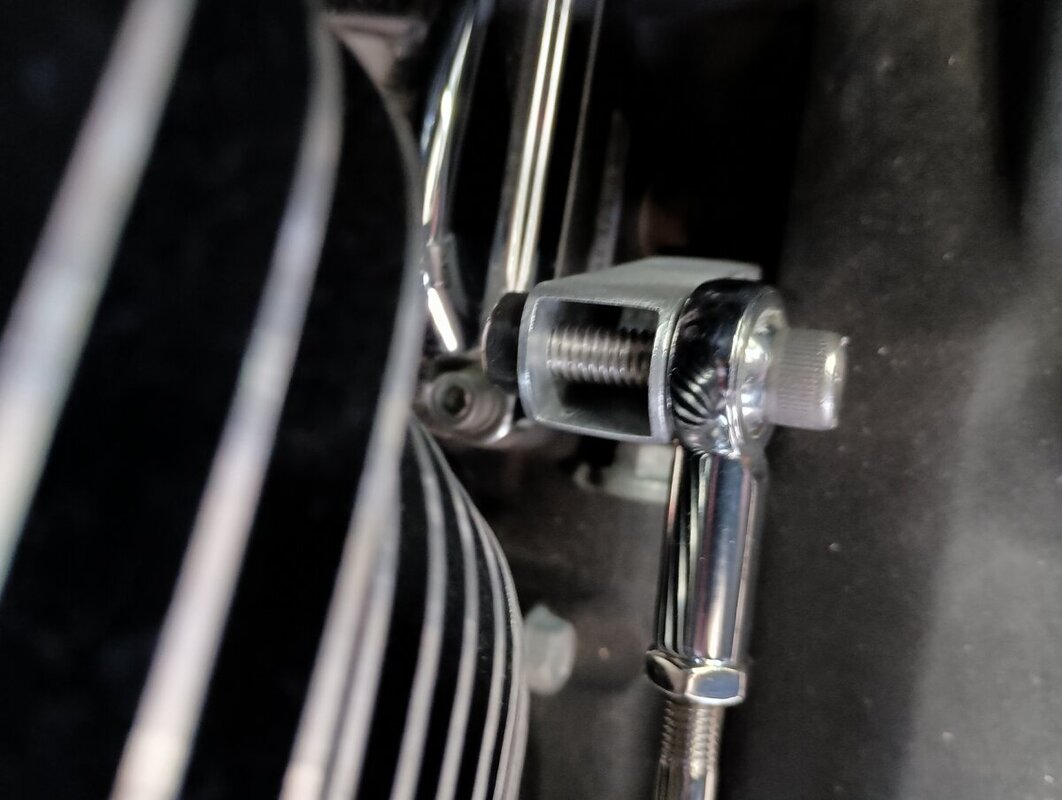

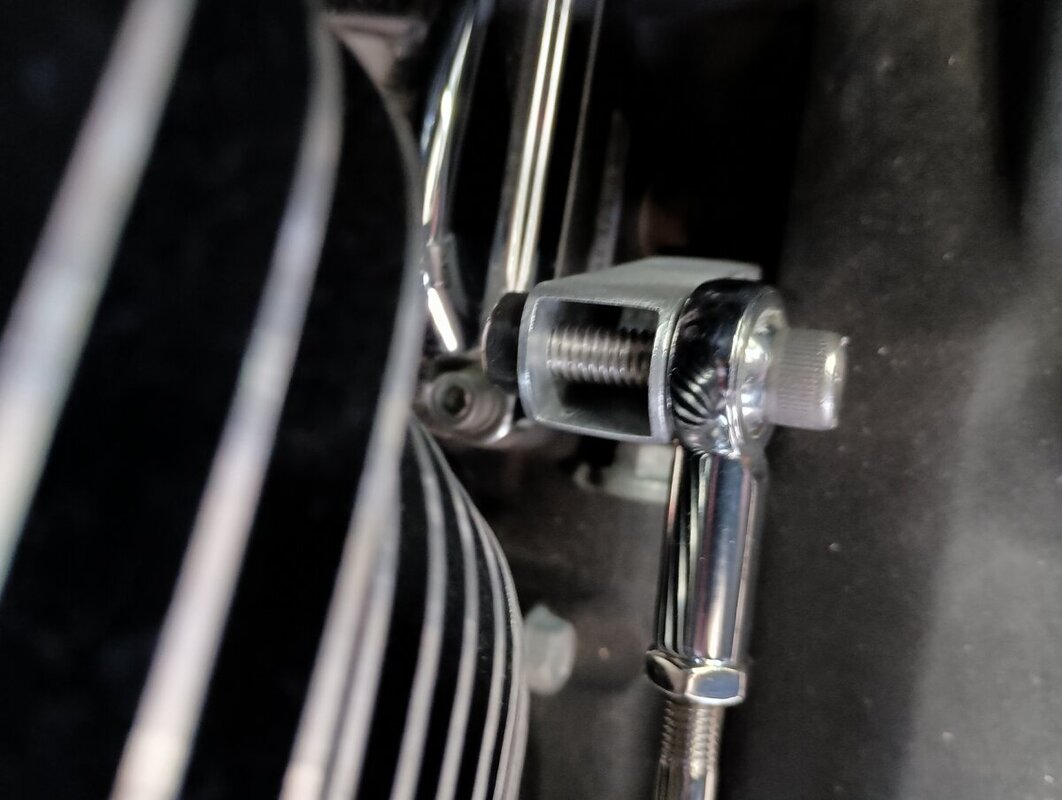

Since I have a 2015 FW with the straight rear shift arm I was looking at ways to easily and cheaply test the Ez Shift theory to see if it actually helps to find neutral. I measured the rear shift arm width to be about 5/8 of an inch. I had a couple ideas but the quick and easy way was taking a piece of Menards steel rack 3/4 inch OD thin wall aluminum square tubing. It slips nicely over the arm

I cut it 2 1/2 inches long and drilled a 5 1/16 thru hole 1 inch from the end then another 17/64 hole another inch up and tapped it thru 5/16 18 . I slid the tube over the shaft and put the bottom bolt in and tightened it securely. I then put a bolt thru the aftermarket rod end and screwed it into the top hole . I then scribed a line around the rod end and removed everything and rounded the end of the tubing for clearance at the top and to match the rod end.

After all that was done I brushed the tubing with my wire wheel on the bench grinder for a bit better appearance. I assembled it again and I added a thin nylock nut to the bottom bolt thru the arm and a regular nut with locktite for the top bolt. I used all stainless bolts also. Now here is the kicker. I just cant believe how much easier this is to find neutral . I did this as a trial but I think it just might be a keeper. I have included pics of the part but dont critique the off center holes and stuff as it was just a test

Besides when its assembled you cant tell the holes are off a bit and it does nothing to hamper the functionality For now I am just going to run this . It was free other than another hour out of my life expectancy

For now I am just going to run this . It was free other than another hour out of my life expectancy  Oh I didnt apply for a patent so if you think you want one then go for it . I also want to add that it seems HD didnt want to find a way to actually keep the linkage straight from the front arm to the rear arm . Neither up or down or side to side. The rear rod end could come out more but thats all an appearance thing. I sure wish I had a nice Bridgeport mill in the garage as I have more ideas !

Oh I didnt apply for a patent so if you think you want one then go for it . I also want to add that it seems HD didnt want to find a way to actually keep the linkage straight from the front arm to the rear arm . Neither up or down or side to side. The rear rod end could come out more but thats all an appearance thing. I sure wish I had a nice Bridgeport mill in the garage as I have more ideas !

Have a great holiday weekend

Dave Jackson,Michigan

I cut it 2 1/2 inches long and drilled a 5 1/16 thru hole 1 inch from the end then another 17/64 hole another inch up and tapped it thru 5/16 18 . I slid the tube over the shaft and put the bottom bolt in and tightened it securely. I then put a bolt thru the aftermarket rod end and screwed it into the top hole . I then scribed a line around the rod end and removed everything and rounded the end of the tubing for clearance at the top and to match the rod end.

After all that was done I brushed the tubing with my wire wheel on the bench grinder for a bit better appearance. I assembled it again and I added a thin nylock nut to the bottom bolt thru the arm and a regular nut with locktite for the top bolt. I used all stainless bolts also. Now here is the kicker. I just cant believe how much easier this is to find neutral . I did this as a trial but I think it just might be a keeper. I have included pics of the part but dont critique the off center holes and stuff as it was just a test

Besides when its assembled you cant tell the holes are off a bit and it does nothing to hamper the functionality

Have a great holiday weekend

Dave Jackson,Michigan