On the few rides I've been able to take so far on this trike, the air shocks don't seem to be providing much to the ride, especially when I hit a pot hole or bump in the road. I already new the control panel didn't seem to pump the shocks, it reads 0, but I kind of assumed there was some residual air or spring function still in the shock. I really bottomed out yesterday on a back road I was on.

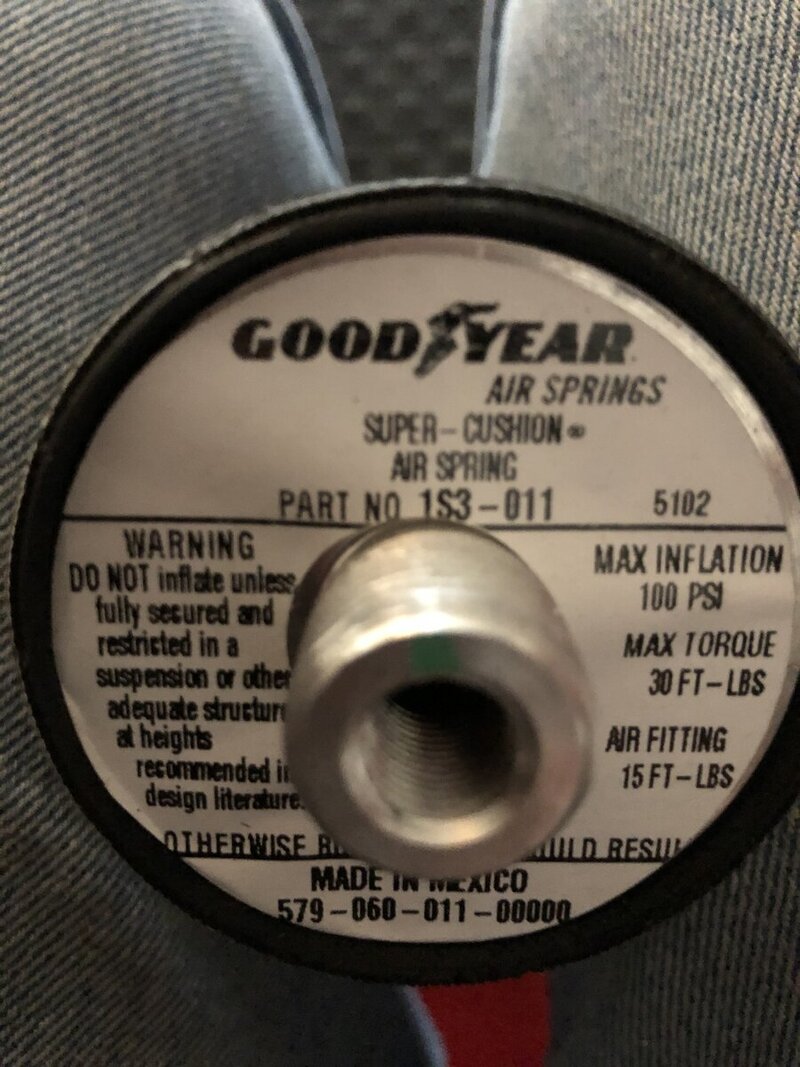

The picture below is of one of the shocks when I had the wheels off that didn't look right where the two halves of the shock meet. Is the rubber that is on the top half of the shock supposed overlap and attach to the bottom of the shock? (I'm assuming most air shocks regardless of the conversion must use similar shocks?) I'm finding more and more things that I think have been neglected on this trike. How do I test the compressor to see if it is pumping? Jack it up so the wheels are hanging and pull both wheels off? How do I test the shocks? How do I even get to the pump?

When I push the button to pump the shocks I get a clicking but no compressor sound. If these shocks need to be replaced are there common automotive brands that I can get or do I have to go to Motor Trike? When I Google up air shocks I see a wide range of prices if I have to replace them or the pump.

Any comments you folks have are appreciated.

The picture below is of one of the shocks when I had the wheels off that didn't look right where the two halves of the shock meet. Is the rubber that is on the top half of the shock supposed overlap and attach to the bottom of the shock? (I'm assuming most air shocks regardless of the conversion must use similar shocks?) I'm finding more and more things that I think have been neglected on this trike. How do I test the compressor to see if it is pumping? Jack it up so the wheels are hanging and pull both wheels off? How do I test the shocks? How do I even get to the pump?

When I push the button to pump the shocks I get a clicking but no compressor sound. If these shocks need to be replaced are there common automotive brands that I can get or do I have to go to Motor Trike? When I Google up air shocks I see a wide range of prices if I have to replace them or the pump.

Any comments you folks have are appreciated.

, all of which were very informative but realize I’m not even sure where the compressor (that only clicks right now), is on my trike???

, all of which were very informative but realize I’m not even sure where the compressor (that only clicks right now), is on my trike???